Tensile-strengthened rubber isolation bearing

A rubber vibration isolation bearing and reinforced technology, which is applied in the direction of earthquake resistance, building type, building components, etc., can solve the problems of affecting structural safety, rupture and damage of the rubber layer of the bearing, and the upper structure swaying and shaking, so as to increase the material cost, The effect of improving deformation capacity and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

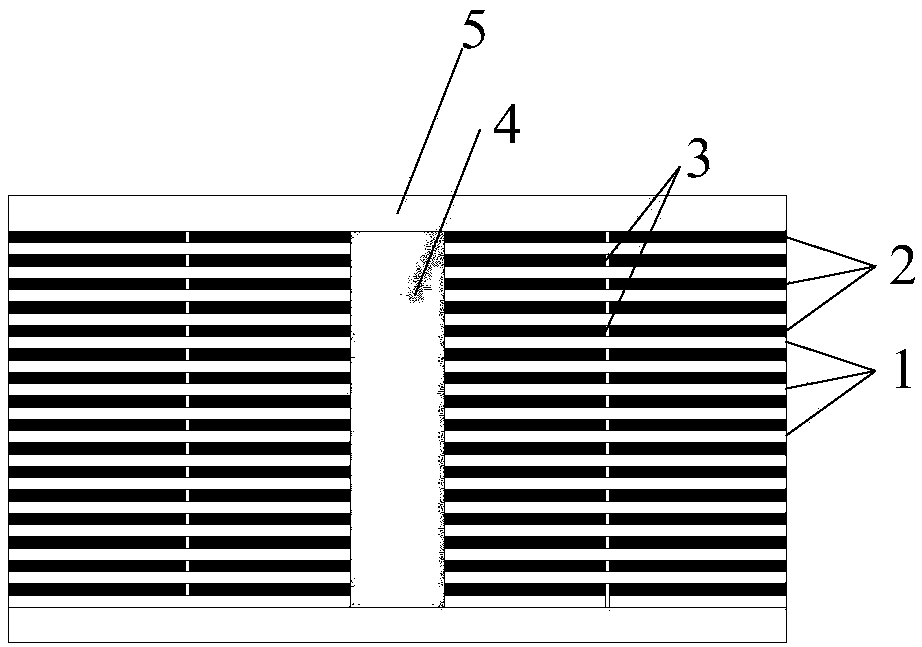

[0024] There are rubber layers (2) between the steel plate layers (1) of the shock-isolation support, and a vertical gap (3) is set in the middle of each rubber layer (2) on both sides of the symmetry plane, and all steel plate layers (1) and rubber layers (2) After forming, energy-consuming components (4) are filled at the symmetrical axis, and finally sealing plates are arranged at the upper and lower ends.

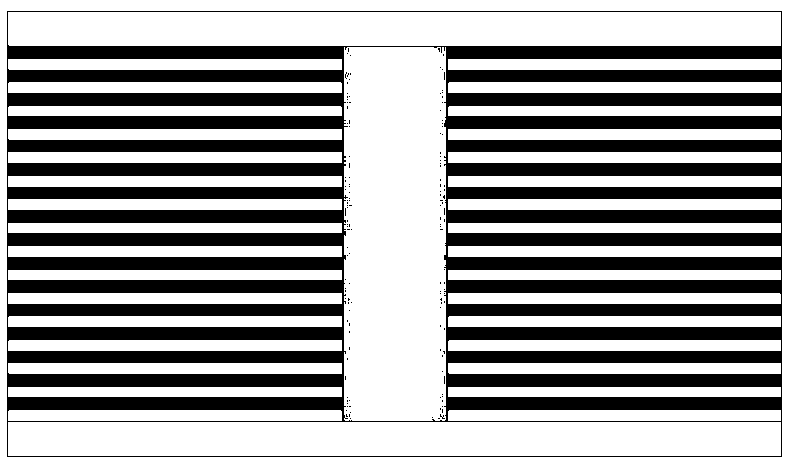

[0025] figure 1 It is a schematic diagram of the front section of the tensile reinforced rubber shock-isolation bearing of the present invention; figure 2 is a frontal cross-sectional schematic diagram of a common rubber shock-isolation bearing; image 3 It is a schematic diagram of the positive section deformation of the tensile reinforced rubber shock-isolating bearing of the present invention under the action of tension F; Figure 4 is the schematic diagram of normal section deformation of ordinary rubber shock-isolating bearing under the action of tension F; Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com