Piezoelectric ceramic conversion device capable of controlling deformation of piezoelectric ceramic piece and manufacturing method thereof

A piezoelectric ceramic sheet, piezoelectric ceramic technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Electric ceramic sheets have problems such as high lead content and environmental pollution to achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

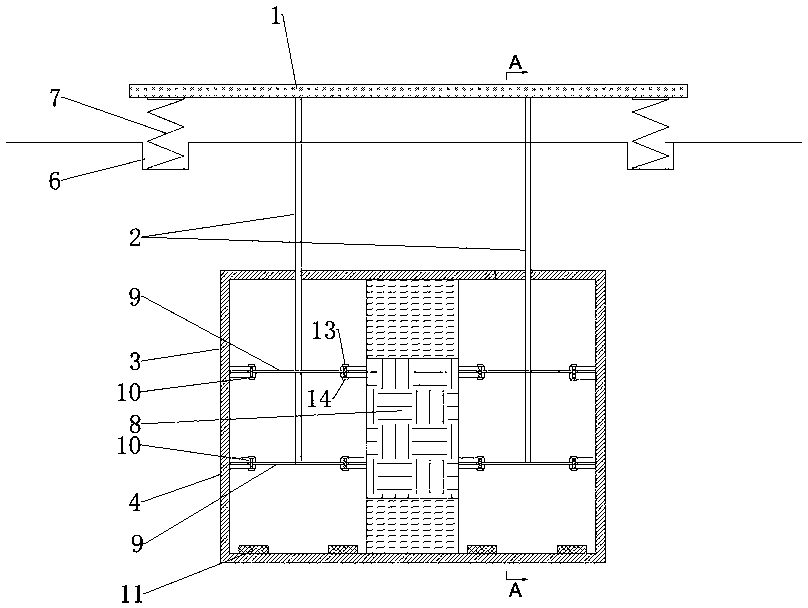

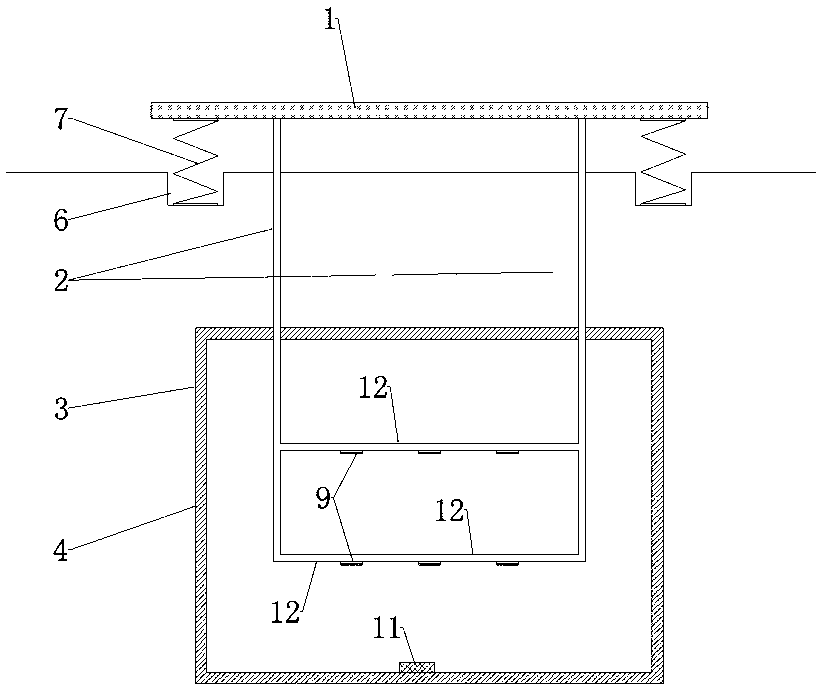

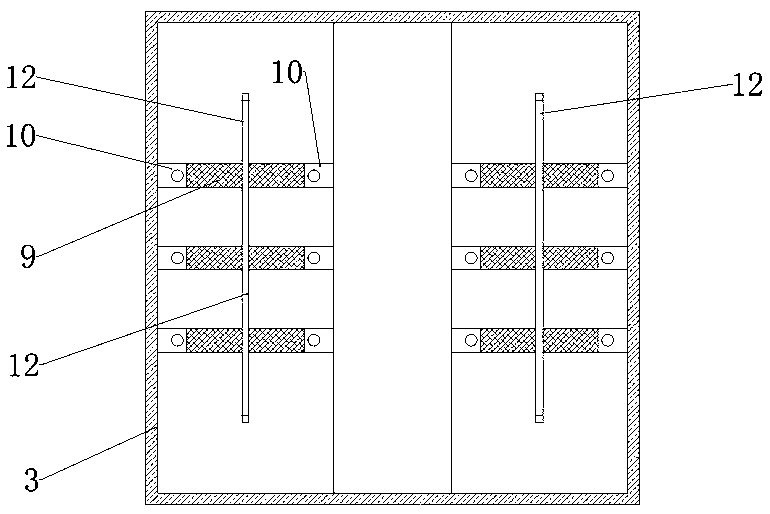

[0029] refer to Figure 1-6As shown, the present invention provides a piezoelectric ceramic conversion device that can control the deformation of piezoelectric ceramic sheets, including a pressure plate 1, a metal frame 2 and a packaging box 3. The pressure plate 1 is installed in the installation groove 4 on the road surface, and the pressure plate 1 is configured with elastic The recovery mechanism, the elastic recovery mechanism includes a spring installation groove 6 and a spring 7, the spring installation groove 6 is set on the road surface below the four corners of the pressure plate 1, and the spring 7 is arranged in the spring installation groove 6; the inner space of the packaging box 3 is divided horizontally There are three compartments, the middle compartment places the circuit board 8, and the side plates of the compartments on both sides are provided with multiple pairs of clamping devices 10 for fixing the piezoelectric ceramic sheet 9, and each pair of clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com