Blasting method and application of using mud as blockage of blasting blast

A blast hole plugging and blast hole technology, which is applied in the field of blasting technology, can solve problems such as unbalanced shear strength and resistance, and achieve the effects of low block rate, high blasting efficiency, and high block uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The blasting concentrator uses ordinary TNT explosive packs;

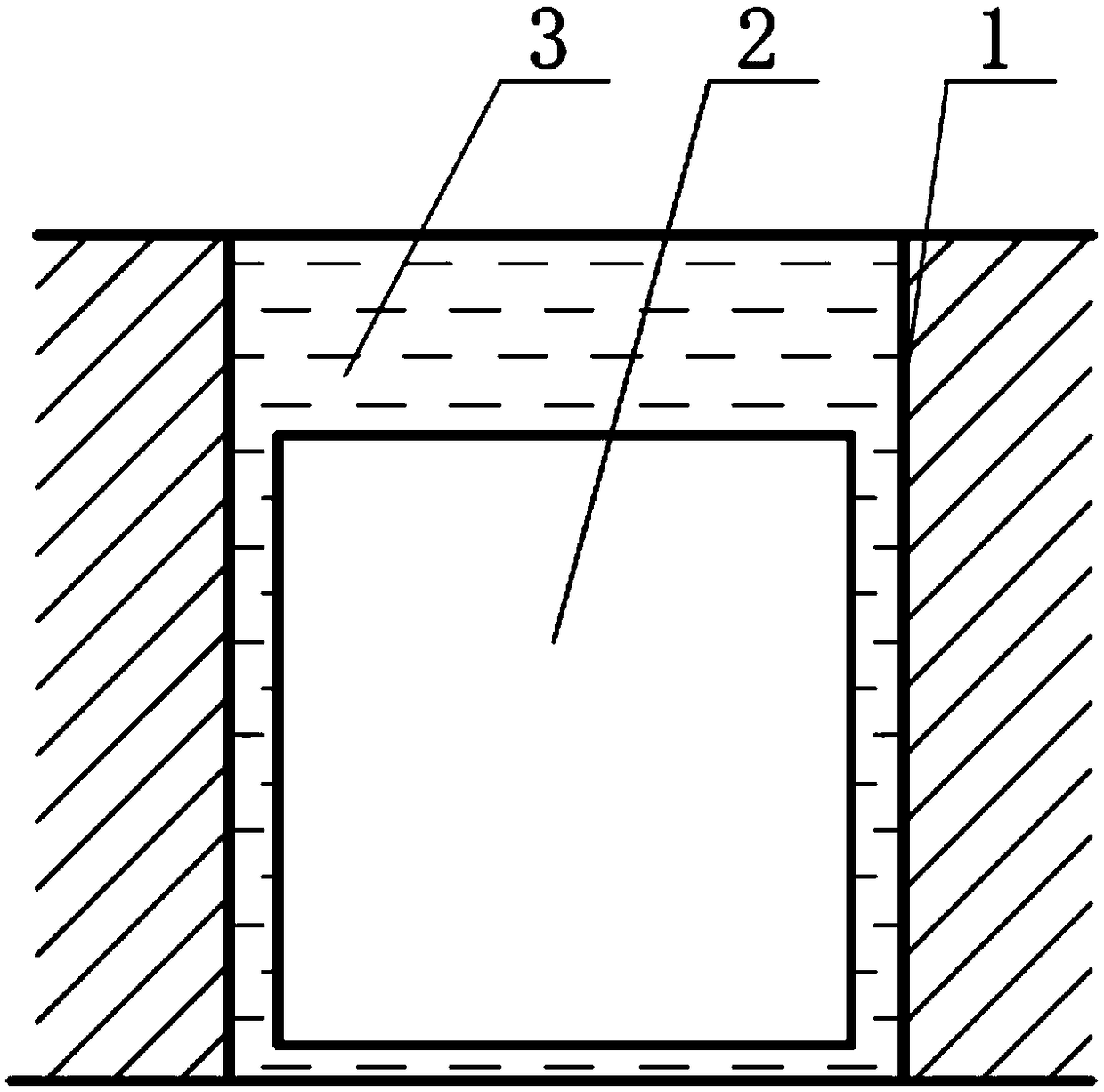

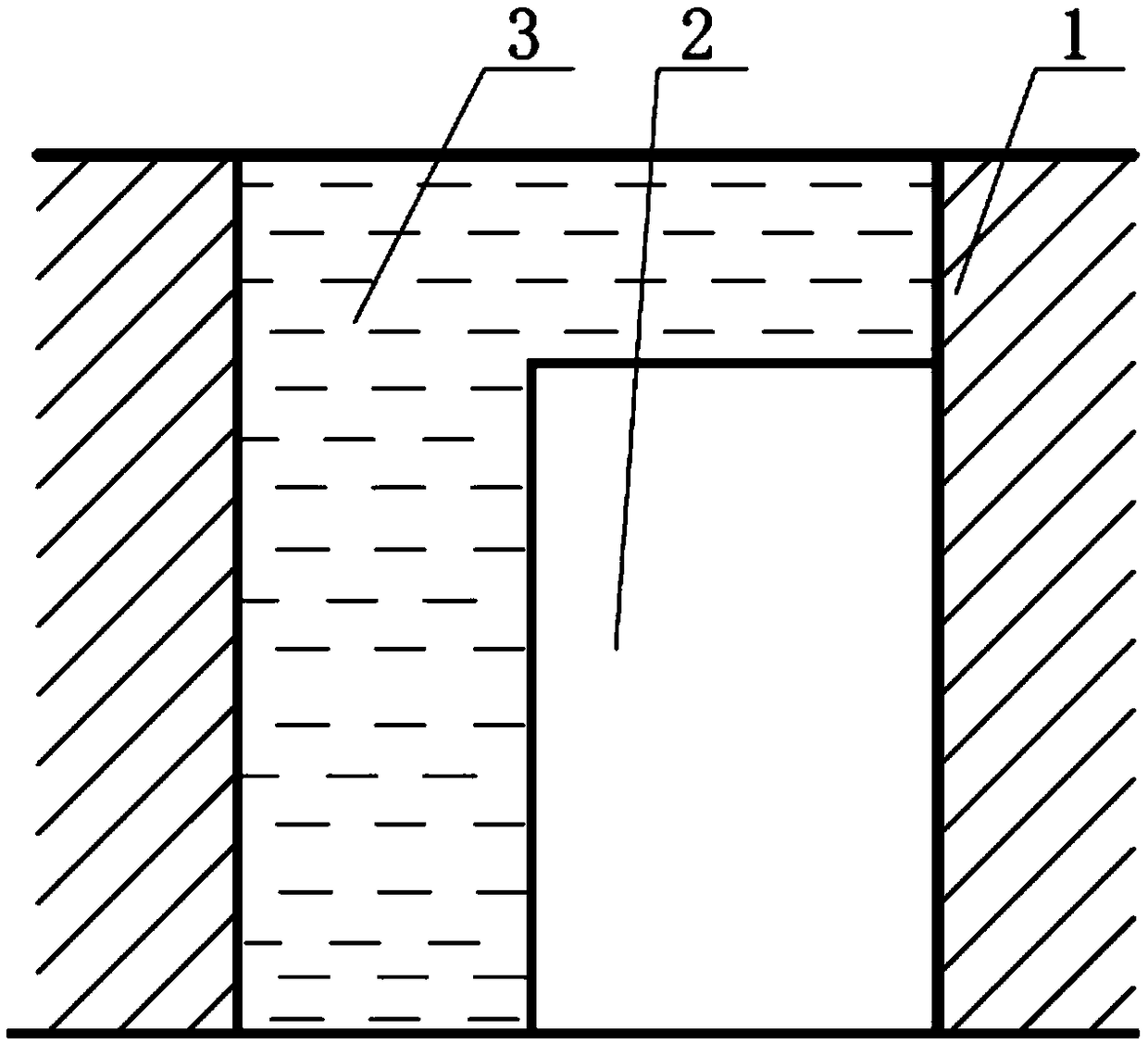

[0093] Excavate a blast hole at the position to be blasted, and place the common TNT explosive pack in the blast hole;

[0094] Pour the mud into the blasting hole where the common TNT explosive pack is arranged, so as to fill the mud between the blasting gun hole and the common TNT explosive pack; wherein, the mud completely seals the blasting gun hole, to completely bury the blasting concentrator in the blasting hole;

[0095] Detonates the blast concentrator.

Embodiment 2

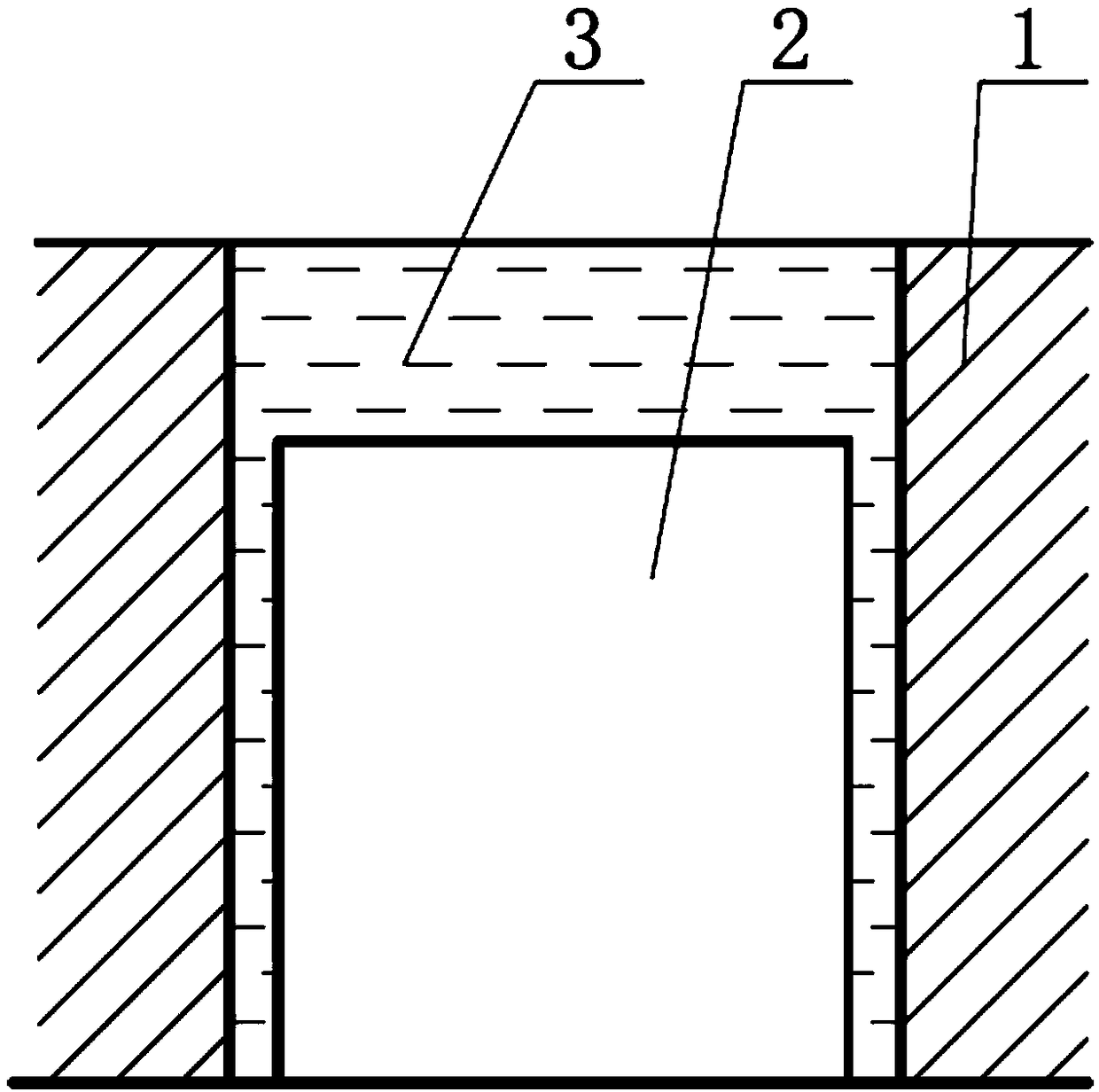

[0097] The blasting concentrator uses gas blasting equipment. For example, in an optional embodiment, CN106643314A can be used. The applicant Guo Yuanjun filed an application on December 21, 2016. , the blaster has the advantages of high power and controllable direction;

[0098] Excavate a blast hole at the position where blasting is to be carried out, and place the gas blasting equipment in the blast hole; pour mud into the blast hole where the gas blast equipment is installed, so that the blast hole and the blast hole The gas blasting equipment is filled with mud; wherein, the mud completely seals the blasting hole, so that the blasting concentrator is completely buried in the blasting hole;

[0099] Detonates the blast concentrator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com