Method for forcibly dismantling concrete support by using high-pressure hydrostatic pressure

A technology of concrete and high-pressure water, which is applied in building maintenance, construction, building construction, etc., can solve problems such as difficult to accurately control pressure changes, affect the construction process, and enlarge the deformation of foundation pits, so as to achieve green, safe, environmentally friendly installation and short construction period. Short, less peripheral effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

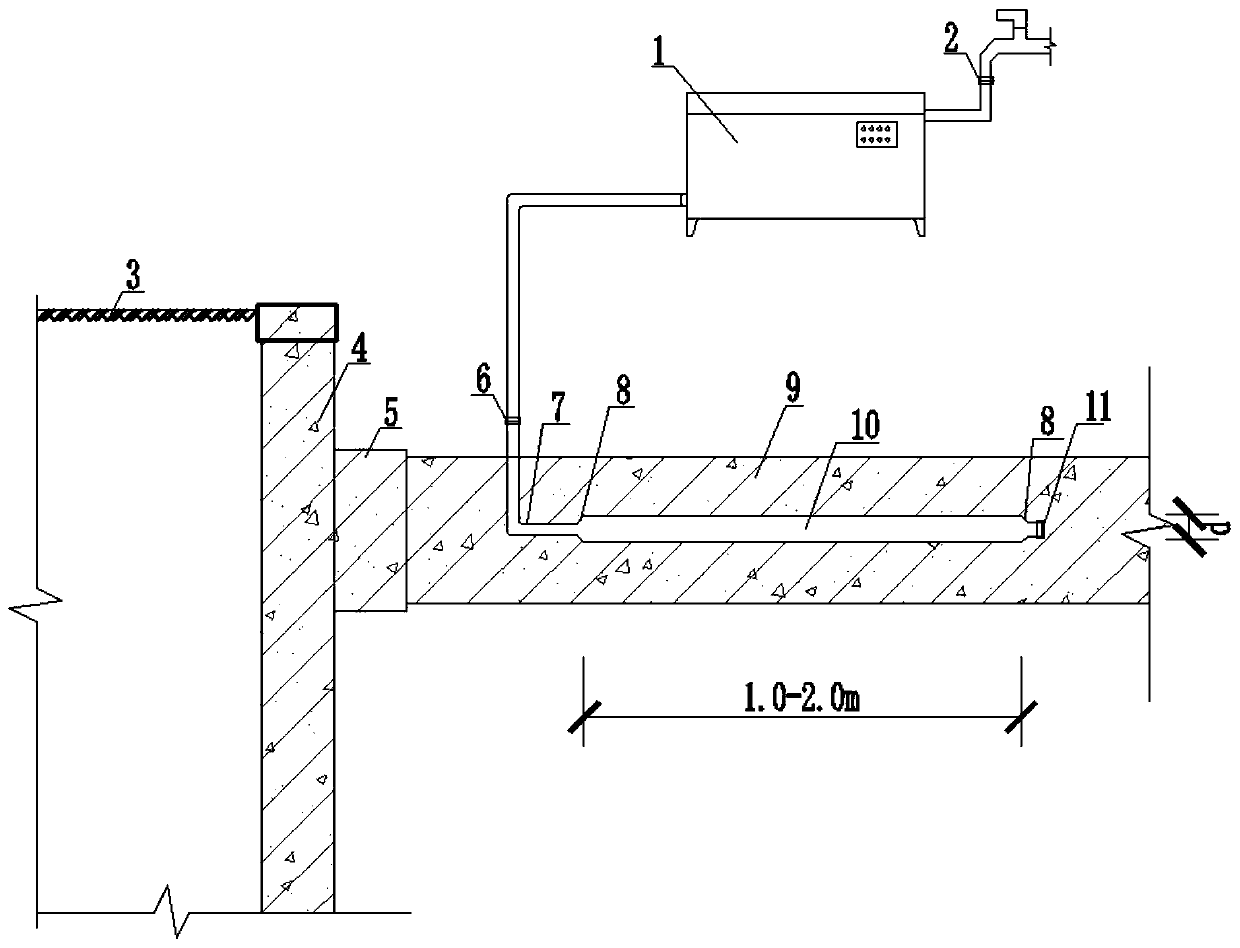

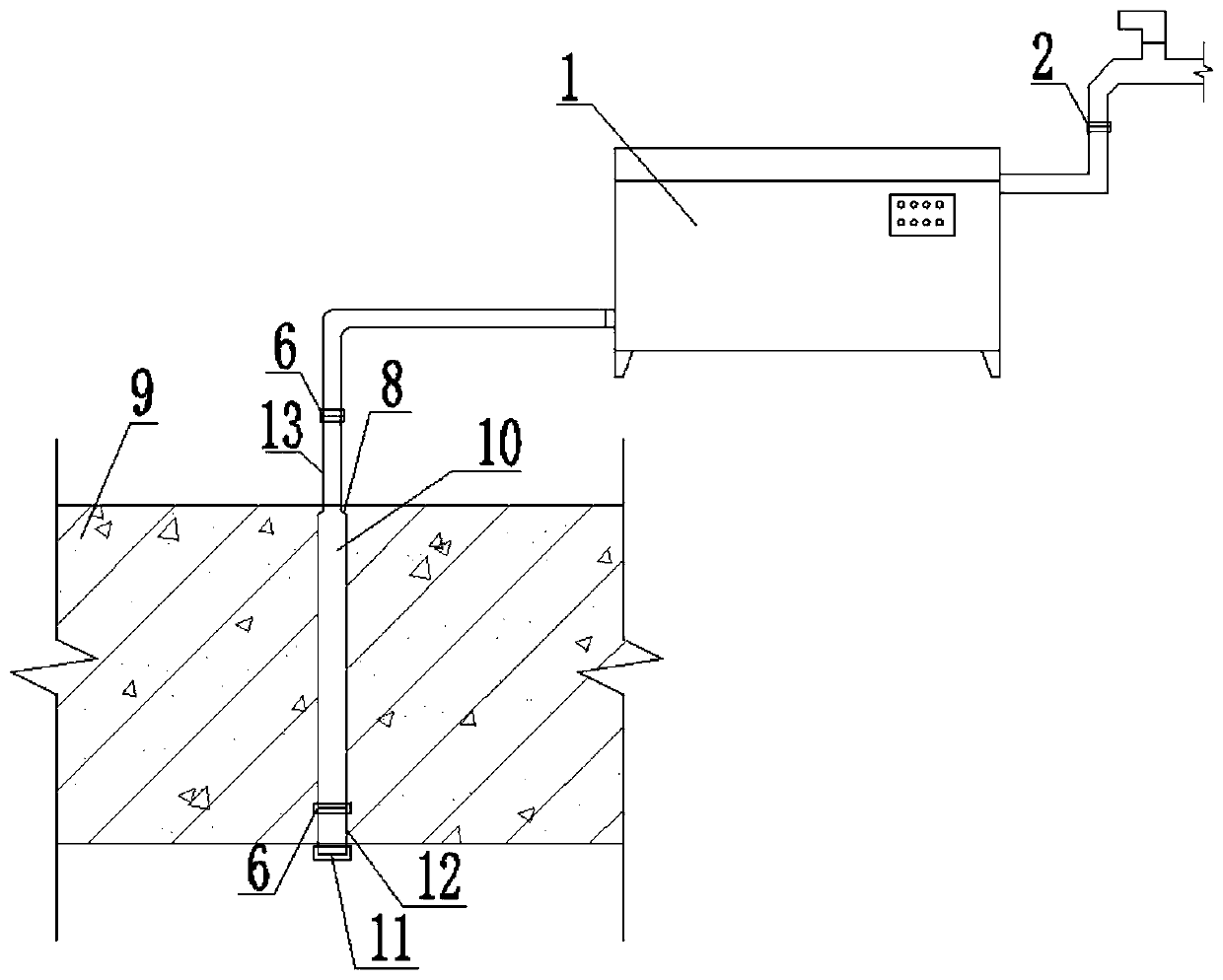

[0027] refer to figure 1 with figure 2 , a method of using high-pressure hydrostatic pressure to demolish concrete supports. The structure of utilizing high-pressure hydrostatic pressure to demolish concrete supports mainly includes: 1-ultra-high water pressure generator, 2-water inlet, 3-ground, 4-surrounding Parapet wall, 5-purlin, 6-joint, 7-elbow, 8-reducing joint, 9-concrete support, 10-high hydrostatic pressure pipe, 11-bulk head, 12-first pipe, 13-second pipe .

[0028] refer to figure 1 As shown, the diameter of the high hydrostatic pressure pipe 10 is d. Before the concrete support 9 is poured, one end of the high hydrostatic pressure pipe 10 is sealed with a bulkhead 11, and the other end is connected to the horizontal port of the elbow 7 through a reducing joint 8. Arrange the assembled high hydrostatic pressure pipe 10 in the middle of the concrete sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com