Household garbage compressing mechanism

A technology for garbage compression and household use, applied in presses, manufacturing tools, etc., can solve the problem of reducing garbage compression time and achieve the effect of reducing garbage compression time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

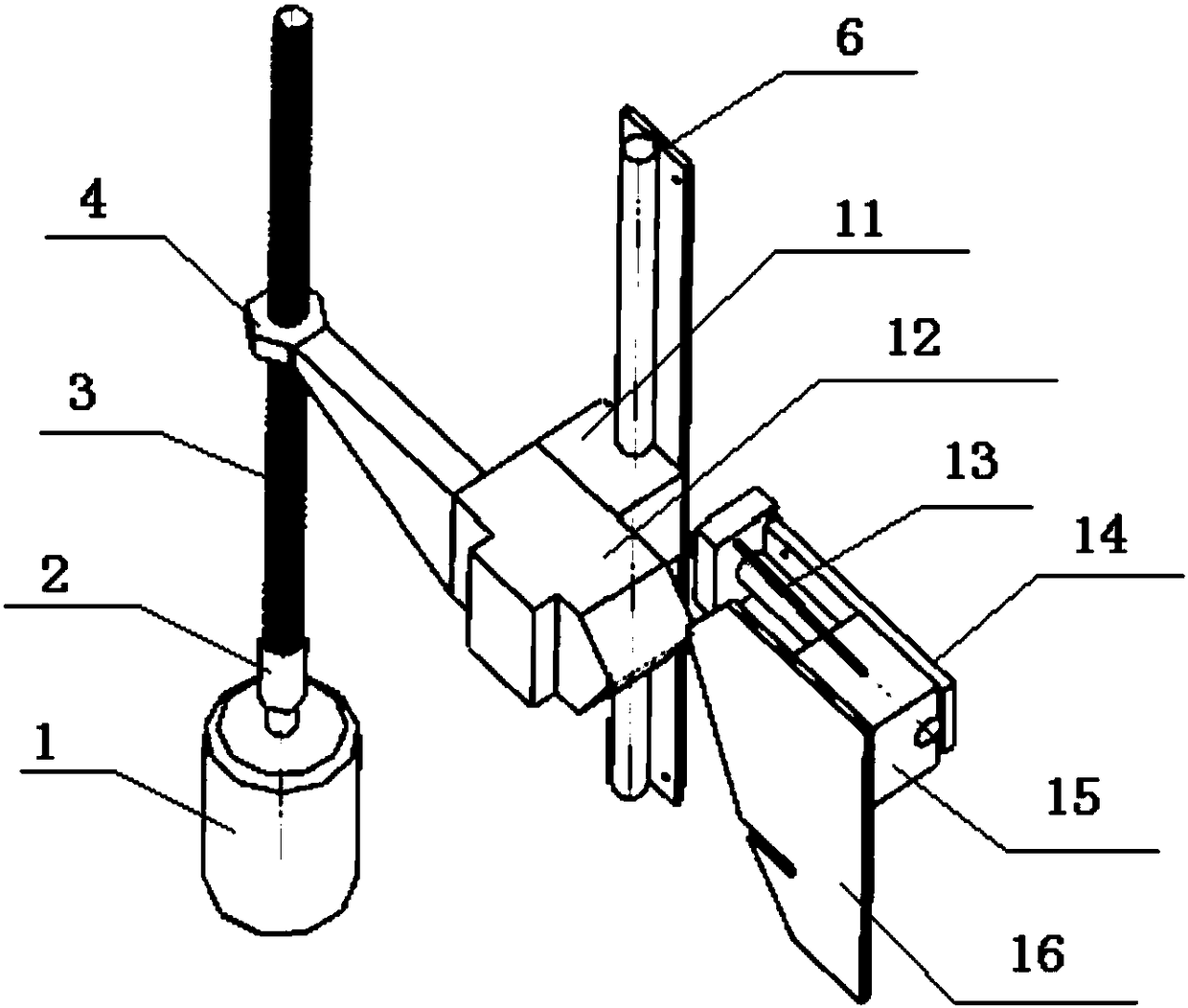

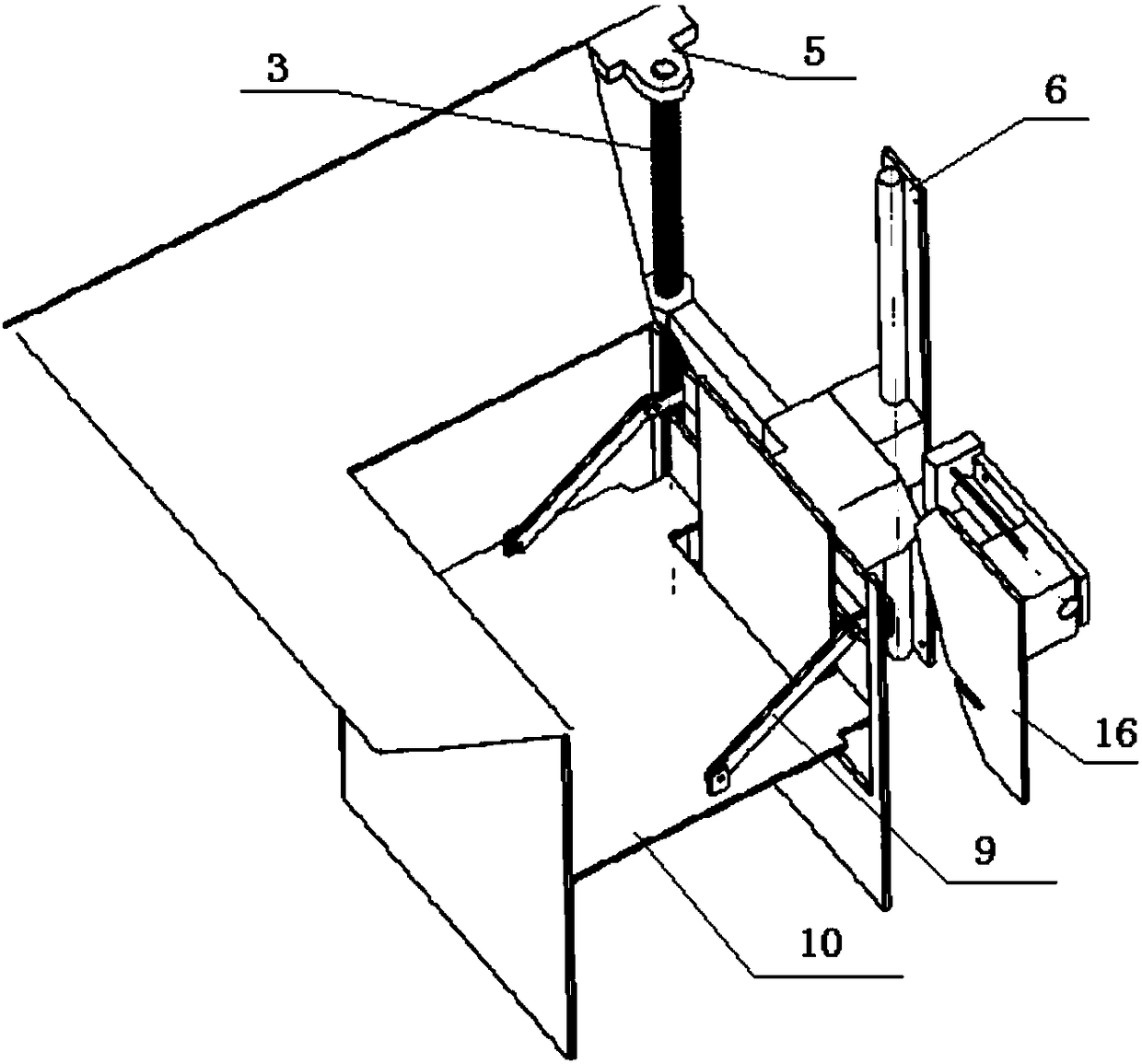

[0006] An automatic compression device driven by a stepping motor, comprising a stepping motor (1), a guide rail (6), a shaft coupling (2), a transmission screw rod (3), a rolling bearing (5), a compression plate (10), a coupling Rod (9), double-slope top block (12), stopper (16), upper top plate (7), lower top plate (8), upper slider (11), lower slider, short guide rail (14), short guide rail Slider (15), return spring one (13); the stepper motor (1) is connected with the transmission screw rod (3) through the shaft coupling (2), and the upper part of the transmission screw rod (3) is connected with the rolling bearing one (5) , the transmission nut (4) is connected with the double-slope top block (12), the double-slope top block (12) is connected with the upper top plate (7) and the upper slider (11), and the upper top plate (7) is connected with the connecting rod (9) Connecting, connecting rod (9) connects compression plate (10) and lower top plate (8), and block (16) is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com