Binder for inorganic fiber and inorganic fiber mat

A technology of inorganic fibers and binders, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of not necessarily obtaining water-soluble binders, lack of solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

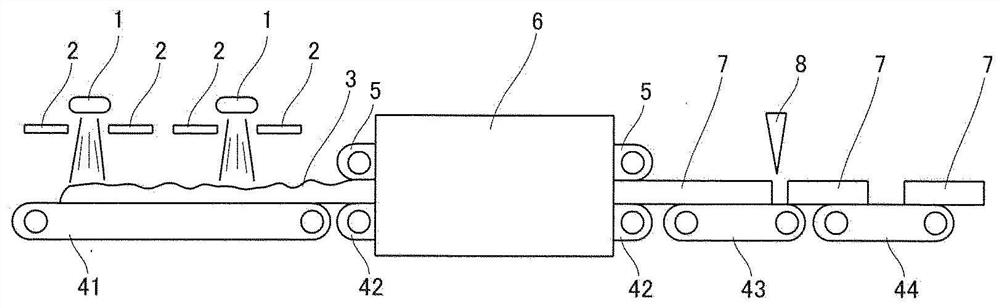

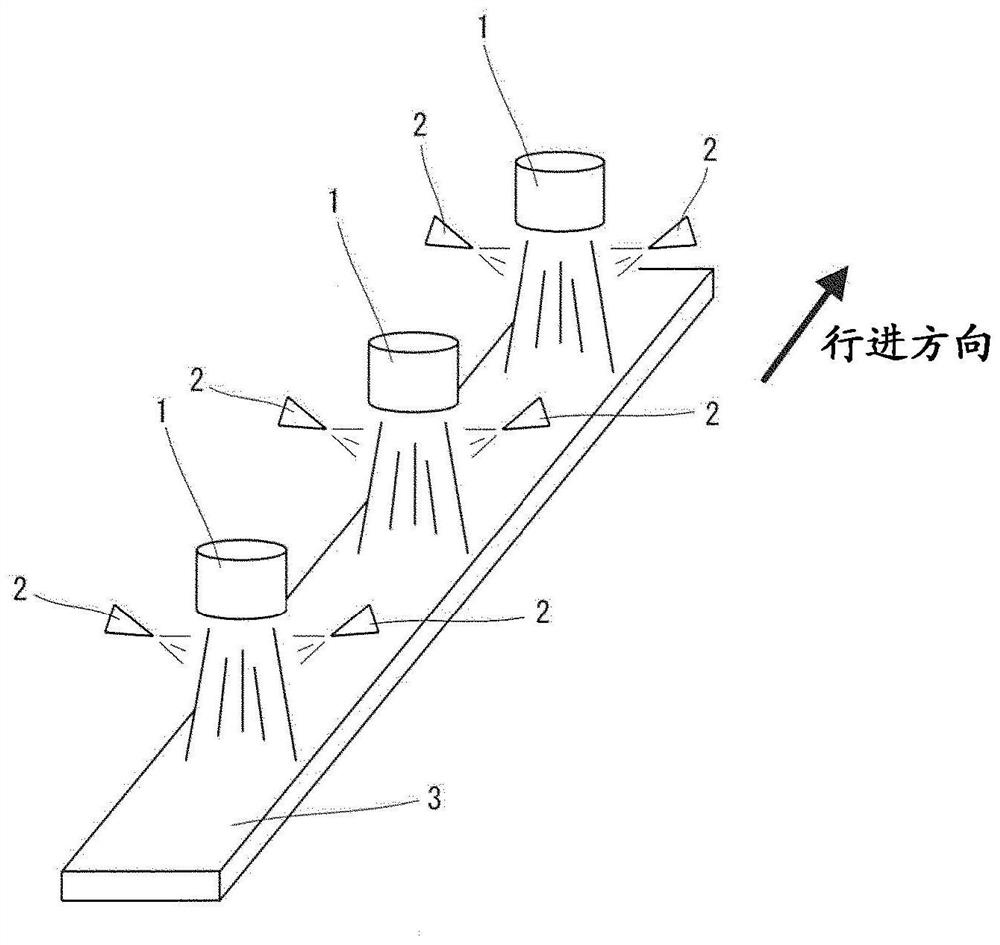

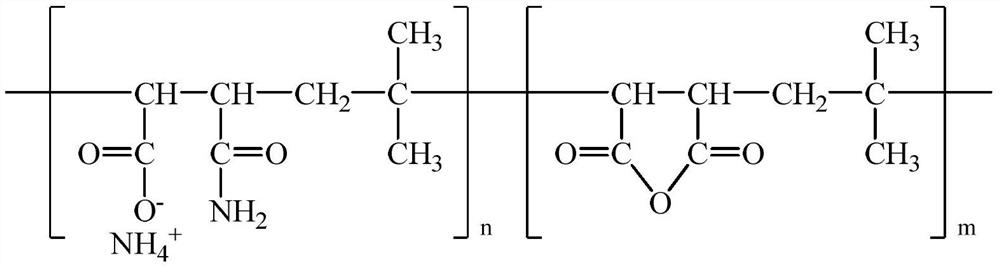

[0081] 100 parts of polyvinyl alcohol described in Table 1 and 5 parts of an ammonia-modified isobutylene-maleic anhydride copolymer were dissolved in ion-exchanged water to prepare an aqueous binder solution for inorganic fibers having a concentration of 2% by mass. As the inorganic fibers, glass wool was used, and the prepared inorganic fiber binder aqueous solution was used to spray the glass wool, and the glass wool was treated by heating and drying at 200° C. for 180 seconds under the treatment conditions in the examples to produce an inorganic fiber mat. The treated amount of the binder for inorganic fibers to the inorganic fiber mat was based on the mass of the treated inorganic fiber mat so that the amount of adhesion to the inorganic fibers was 4% in terms of the solid content ratio of the binder for inorganic fibers.

Embodiment 5~8

[0083] In Example 1, except that the amount of the ammonia-modified product of the isobutylene-maleic anhydride copolymer was changed to 3 parts, 7 parts, 10 parts, and 20 parts, the same manufacturing method as in Example 1 was used to prepare inorganic fibers. Binder aqueous solution, produced inorganic fiber mat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com