Black titanium oxynitride pigment, method for producing the same, and resin compound for encapsulating semiconductor using black titanium oxynitride pigment

A technology of titanium oxynitride and manufacturing method, which is applied in the direction of titanium oxide/hydroxide, nitrogen compound, semiconductor devices, etc., to achieve the effect of improving covering, high electrical insulation, and high α-ray shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

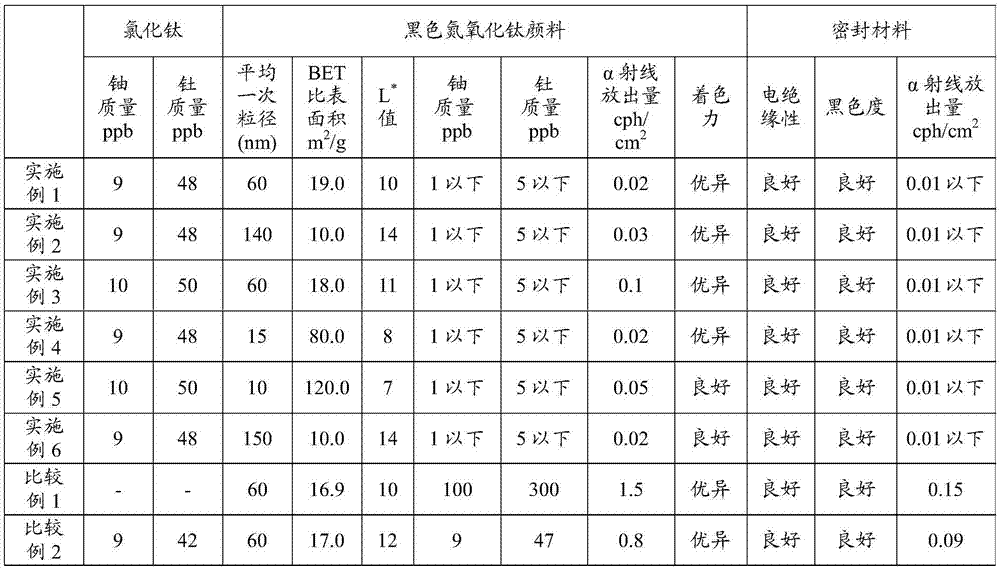

[0035] Next, examples of the present invention will be described in detail together with comparative examples.

[0036]

[0037] First, titanium chloride is treated by distillation (impurity reduction method) at a temperature range of 130 to 140° C. to reduce uranium content and thorium content in titanium chloride, respectively. Next, 45 moles of isopropanol (alcohol) was added to 10 moles of distilled titanium chloride, and titanium chloride and isopropanol (alcohol) were reacted to produce titanium tetraisopropoxide (titanium alkoxide). . Furthermore, titanium tetraisopropoxide was distilled for 5 hours by vacuum distillation (temperature 130-150° C., pressure 10-20 Pa) to reduce the content of uranium and thorium in titanium tetraisopropoxide. Next, the distilled titanium tetraisopropoxide was hydrolyzed to produce a white titanium oxide pigment (TiO 2 ). And, utilize the ammonia gas of flow rate 10 liters / min to above-mentioned white titanium oxide pigment (TiO 2 ) ...

Embodiment 2

[0039] Utilize ammonia gas to the white titanium oxide pigment (TiO2) used in embodiment 1 2 ) is reduced to obtain a black titanium oxynitride pigment, but the ammonia flow rate and the reaction time during this reduction are each set as half of that of Example 1. Ethanol was added as alcohol to the black titanium oxynitride pigment, the black titanium oxynitride pigment was dispersed in ethanol, and wet pulverized by a bead mill to obtain a black titanium oxynitride pigment dispersion with an average primary particle size of 140 nm. The black titanium oxynitride pigment is composed of the chemical formula: TiN X o Y (wherein, X=0.2, Y=0.8). Furthermore, the above-mentioned dispersion liquid was subjected to solid-liquid separation and dried to obtain a black titanium oxynitride pigment. This black titanium oxynitride pigment was referred to as Example 2.

Embodiment 3

[0041] A black titanium oxynitride pigment was obtained in the same manner as in Example 1 except that the temperature during vacuum distillation of tetraisopropoxytitanium was 180°C. This black titanium oxynitride pigment was referred to as Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com