A test bench for oil cylinder seals

A technology of oil cylinder sealing and test bench, which is applied in the testing of fluid pressure actuation system, mechanical equipment, fluid pressure actuating device, etc., can solve the problem that the sealing performance of oil cylinder cannot be directly measured, so as to improve the test efficiency and reduce the work content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

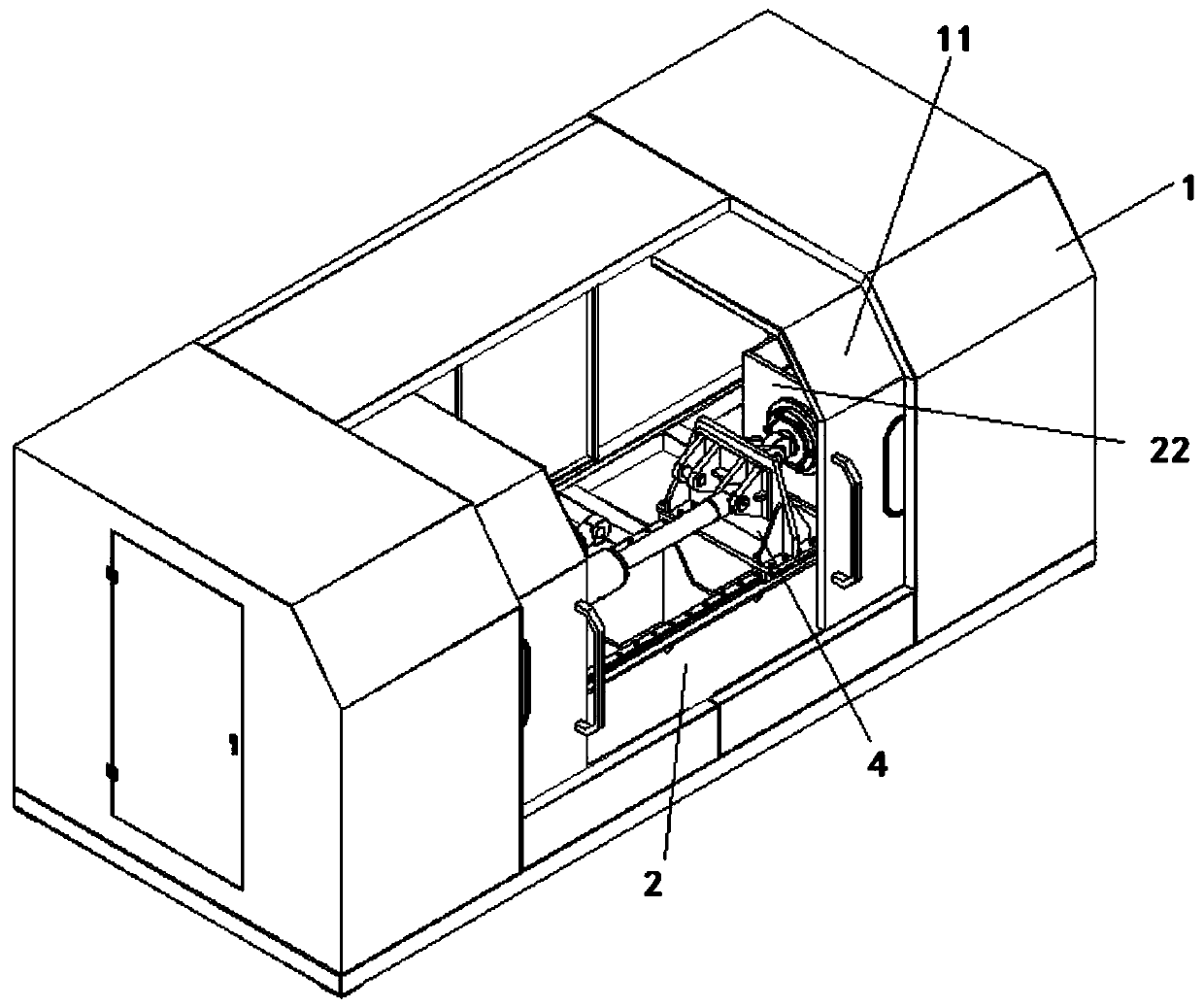

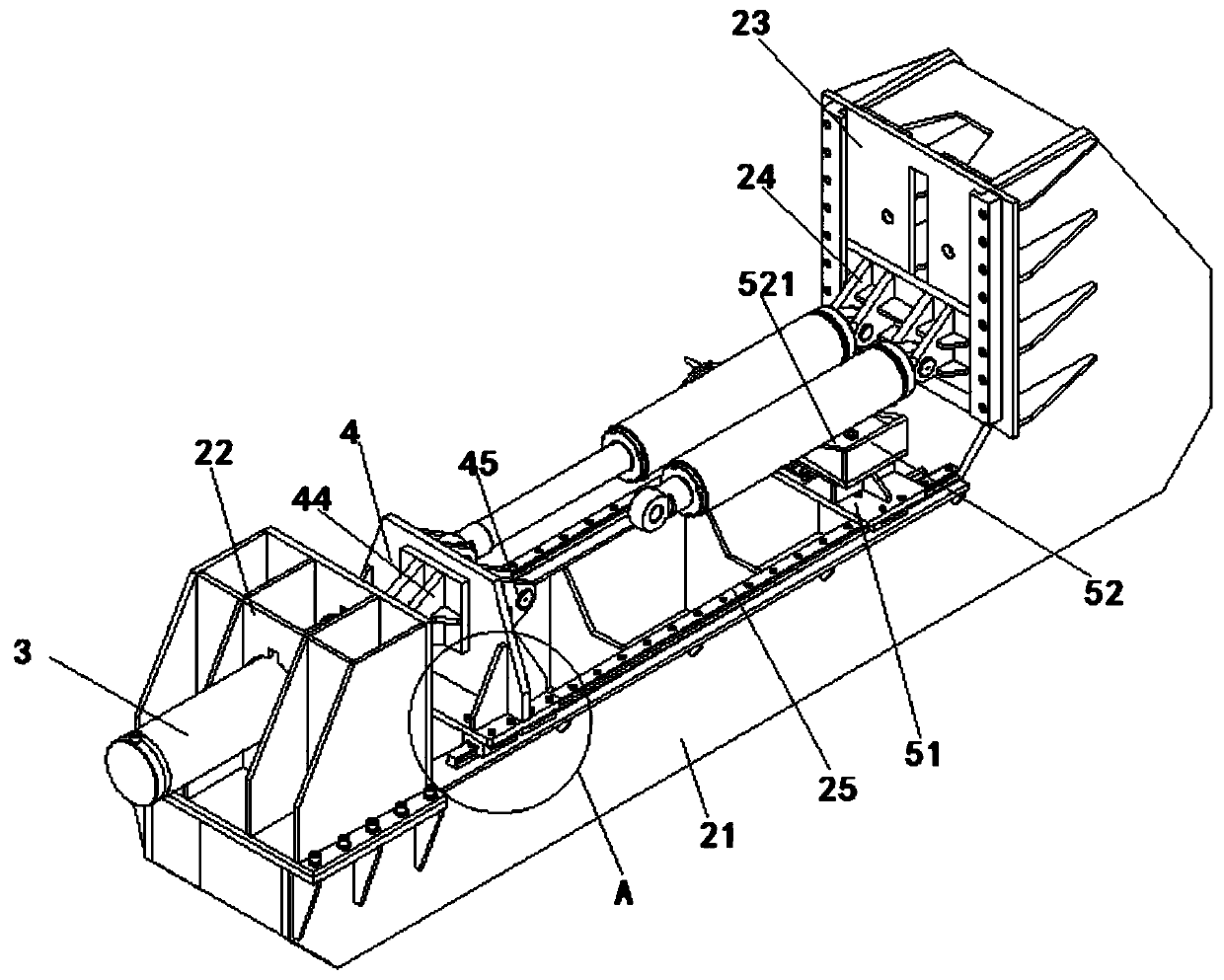

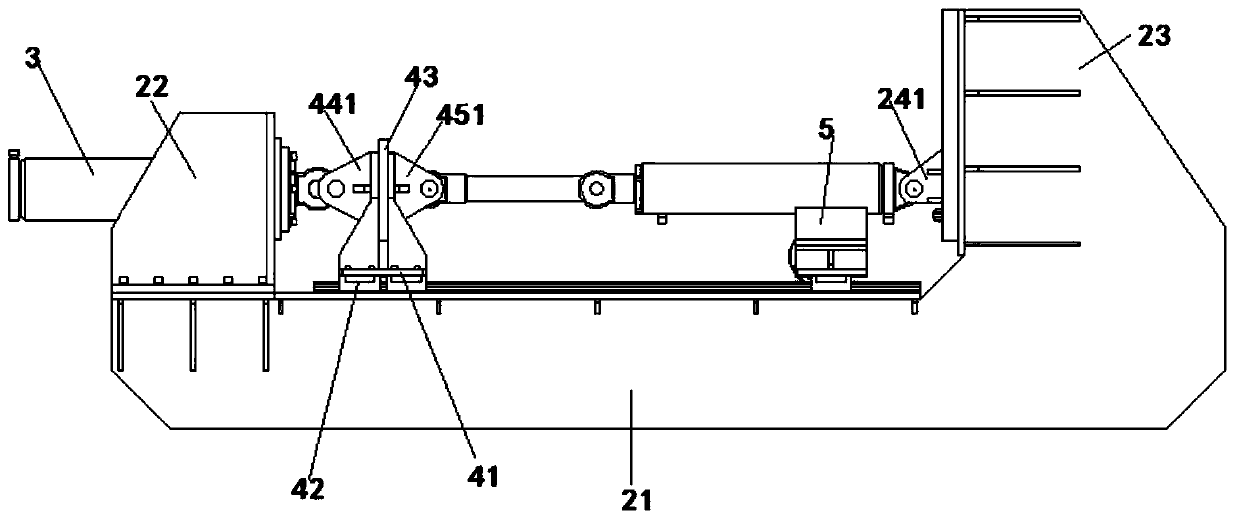

[0017] A cylinder seal test bench, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a cabinet 1 and a rack 2 installed in the cabinet 1. A sliding door 11 is provided in the middle of the front side of the cabinet 1. The opening and closing of the sliding door 11 can prevent dust from entering, and at the same time, the experimental oil cylinder can be put into the rack. 2 for testing;

[0018] The frame 2 comprises a support frame 21 and a first positioning seat 22 and a second positioning seat 23 installed and fixed on both sides of the support frame 21 top, the first positioning seat 22 and the second positioning seat 23 are arranged oppositely, and the first positioning seat 22 The middle part of the loading cylinder 3 is installed, the power end of the loading cylinder 3 is equipped with a sliding seat assembly 4, the loading cylinder 3 is connected to the hydraulic power station, and the hydraulic power station is connected to the computer; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com