Special speed reducer for offshore pulling steel cable

A technology of reducer and steel cable, applied in mechanical equipment, transmission parts, gear transmission and other directions, can solve problems such as affecting the service life of the reducer, bumping vibration affecting the power transmission of the winch workshop, etc., to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

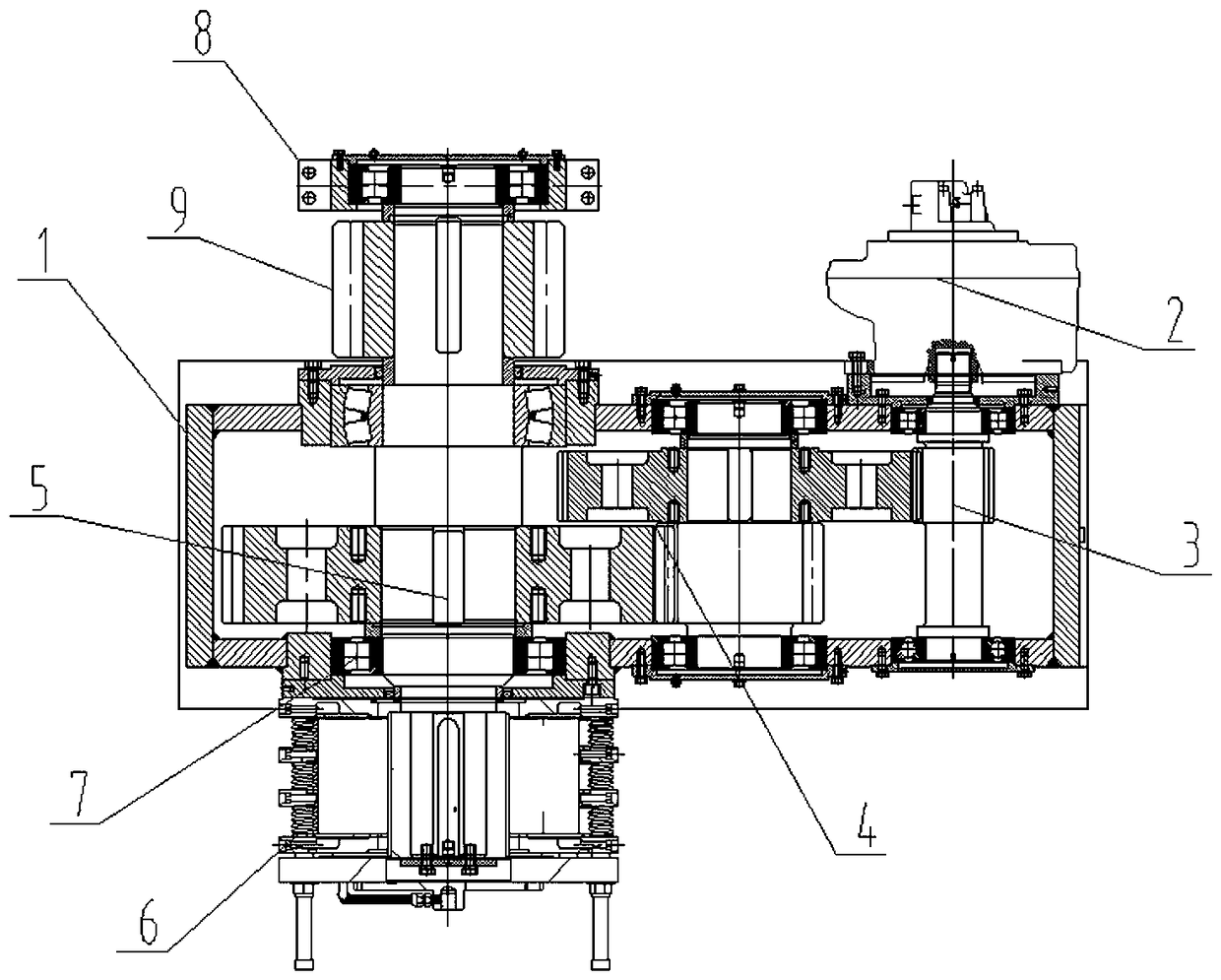

[0010] figure 1 A special reducer for pulling steel cables at sea includes a box body 1, a motor 2, an input shaft 3, a cylindrical gear transmission mechanism 4, an output shaft 5, a damper 6, an NJ bearing 7, a bearing seat 8, and a winch meshing gear 9. The two-stage cylindrical gear transmission mechanism 4 is not in the same horizontal plane and supported in the box body 1, the motor 2 is connected to the input shaft 3, and the input shaft 3 drives the output shaft 5 through the two-stage cylindrical gear transmission mechanism 4, and one end of the output shaft 5 extends out of the box body 1 Connect the damper 6 and this end is supported in the box by the NJ bearing 7, the other end of the output shaft 5 extends out of the box and is supported on the bearing seat 8 by the NJ bearing, and the other end of the output shaft extends out of the box and is connected by a key The winch engages gear 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com