Flexible and convenient drop hammer impact testing machine for building material testing

A technology of drop weight impact test and building materials, applied in the direction of impact test, machine/structural component test, measuring device, etc., which can solve the problems of secondary impact, deviation of results, displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

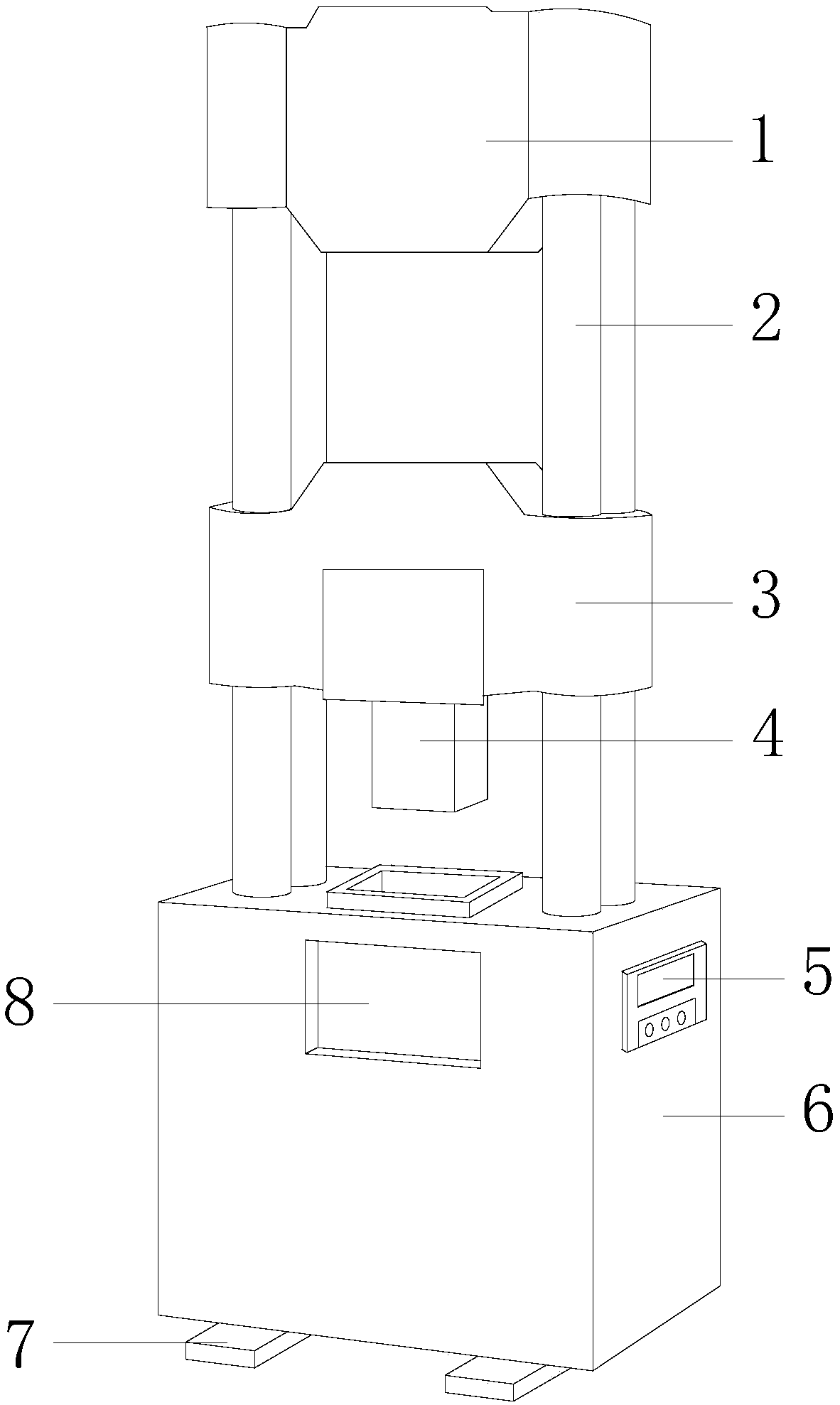

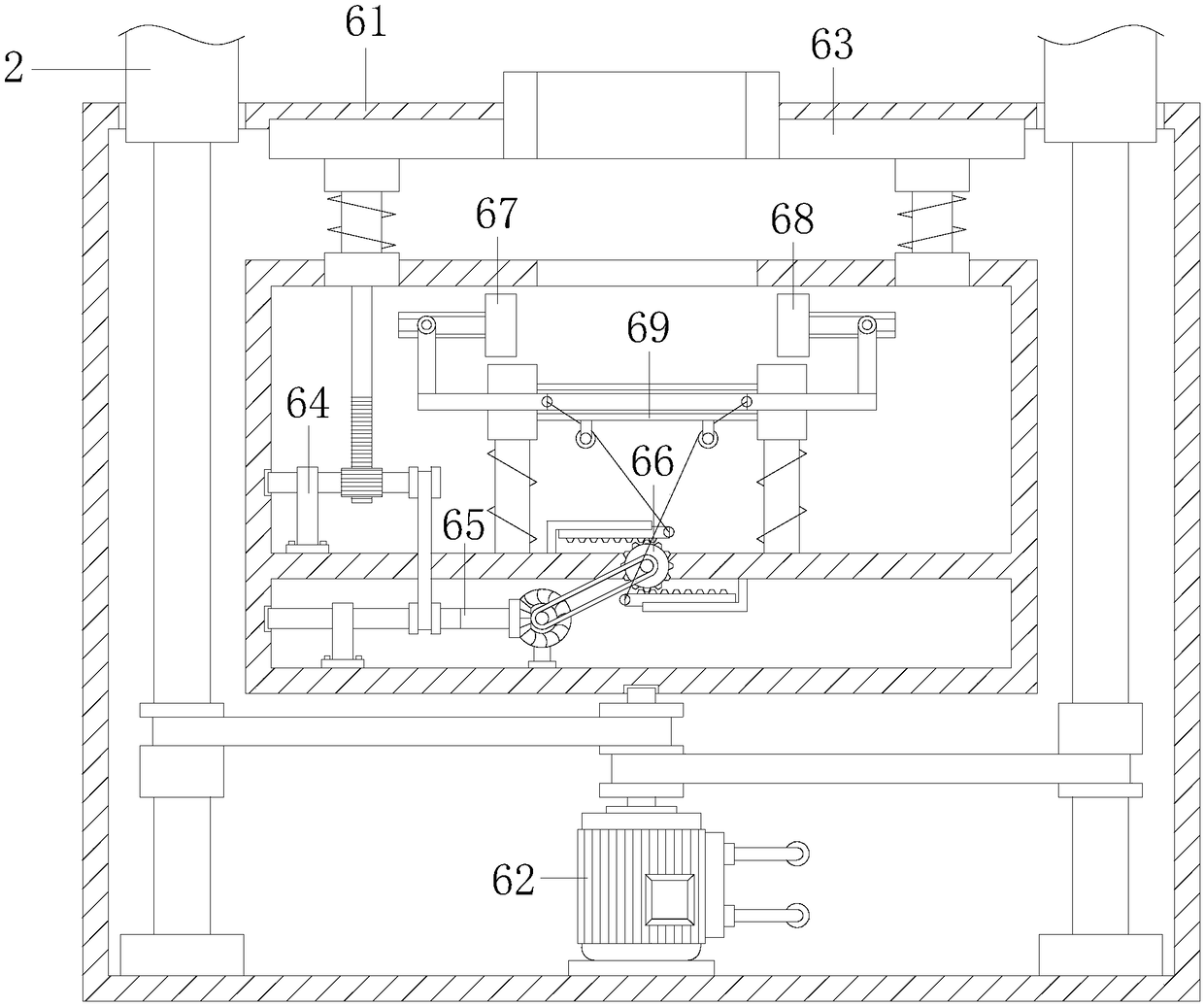

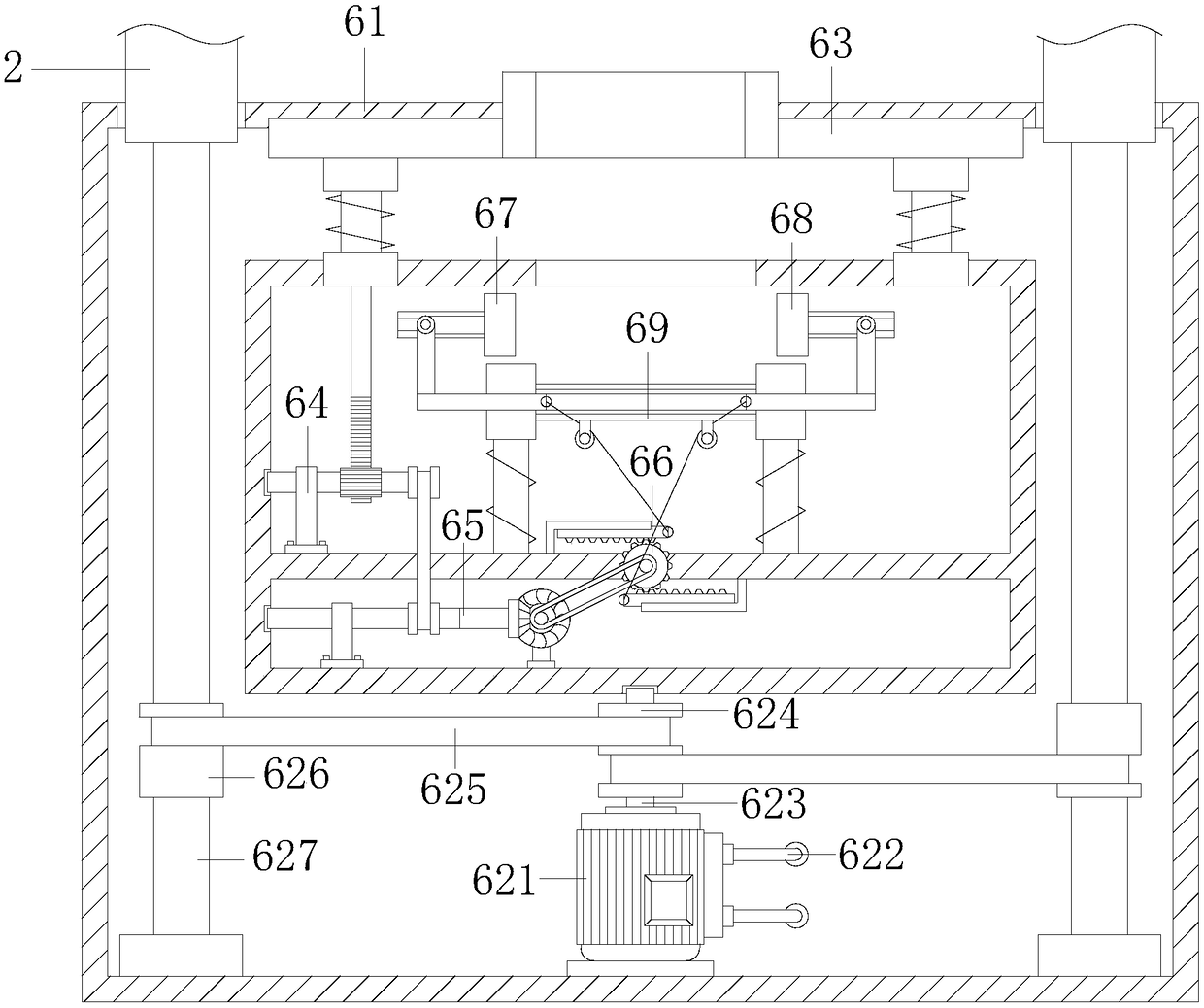

[0024] see Figure 1-Figure 4 , the present invention provides a flexible and convenient drop weight impact testing machine for building material detection, its structure includes a limit top seat 1, a polished rod 2, a lifter 3, a drop weight 4, a control panel 5, an impact detection host 6, and a foot 7. Viewing window 8, the limit top seat 1 is fixedly installed on the upper end of the polished rod 2, the polished rod 2 runs through the interior of the lifter 3, the bottom end of the lifter 3 is provided with a drop hammer 4, and the control panel 5 is embedded in the The outer surface of the impact detection host 6 is electrically connected by wires. The lower end of the polished rod 2 is installed inside the impact detection host 6 in an embedded manner. There are two feet 7 and they are fixedly installed at the bottom of the impact detection host 6. The window 8 is embedded in the front surface of the impact detection host 6, and the impact detection host 6 includes a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com