An automatic brush plating repair device for automobile engine connecting rod

A technology of automobile engine and electric brush plating, which is applied in the direction of electrolytic components, electrolytic process, cells, etc., can solve the problems of inconvenient and flexible cleaning and maintenance of devices, easy precipitation of solutions, and inconvenient and flexible addition and treatment of electroplating solutions, etc., so as to facilitate maintenance and maintenance Stirring structure, convenient and quick cleaning, and the effect of preventing pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

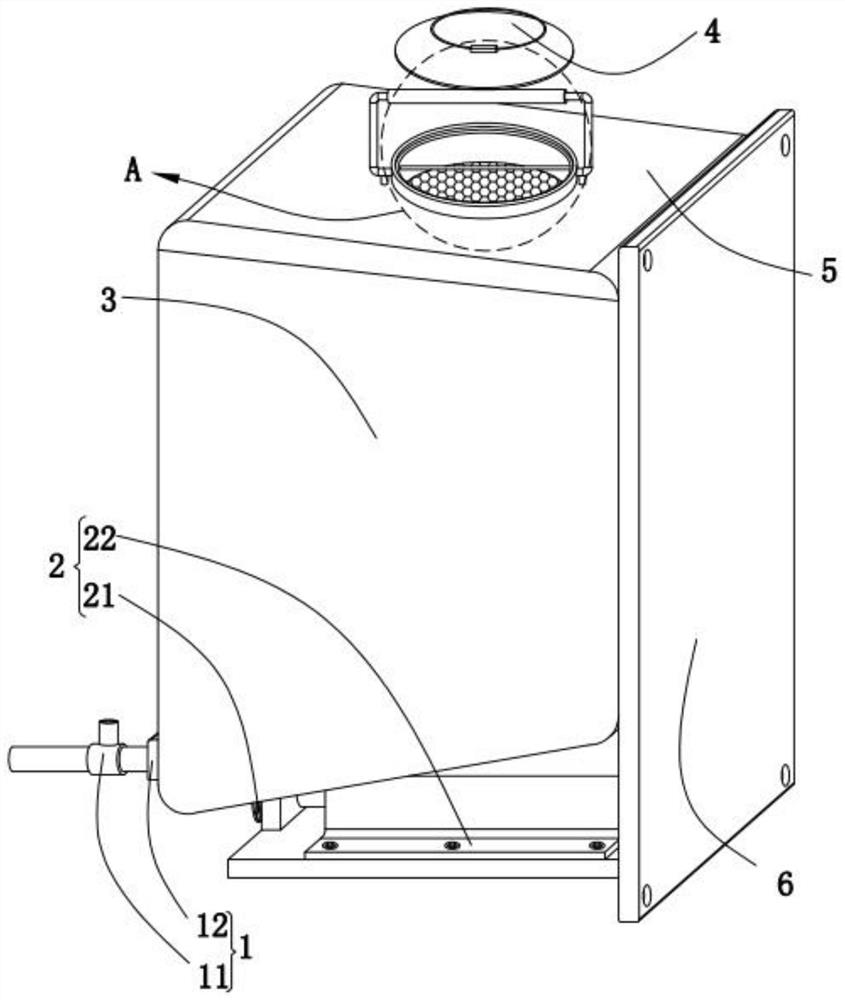

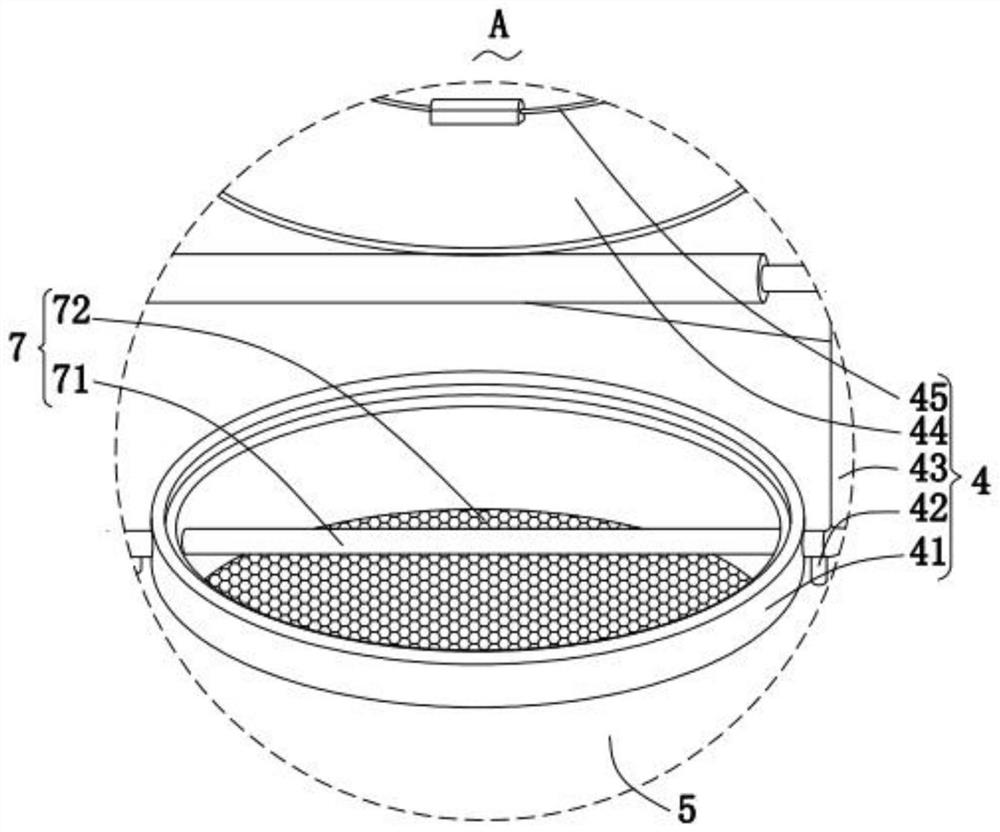

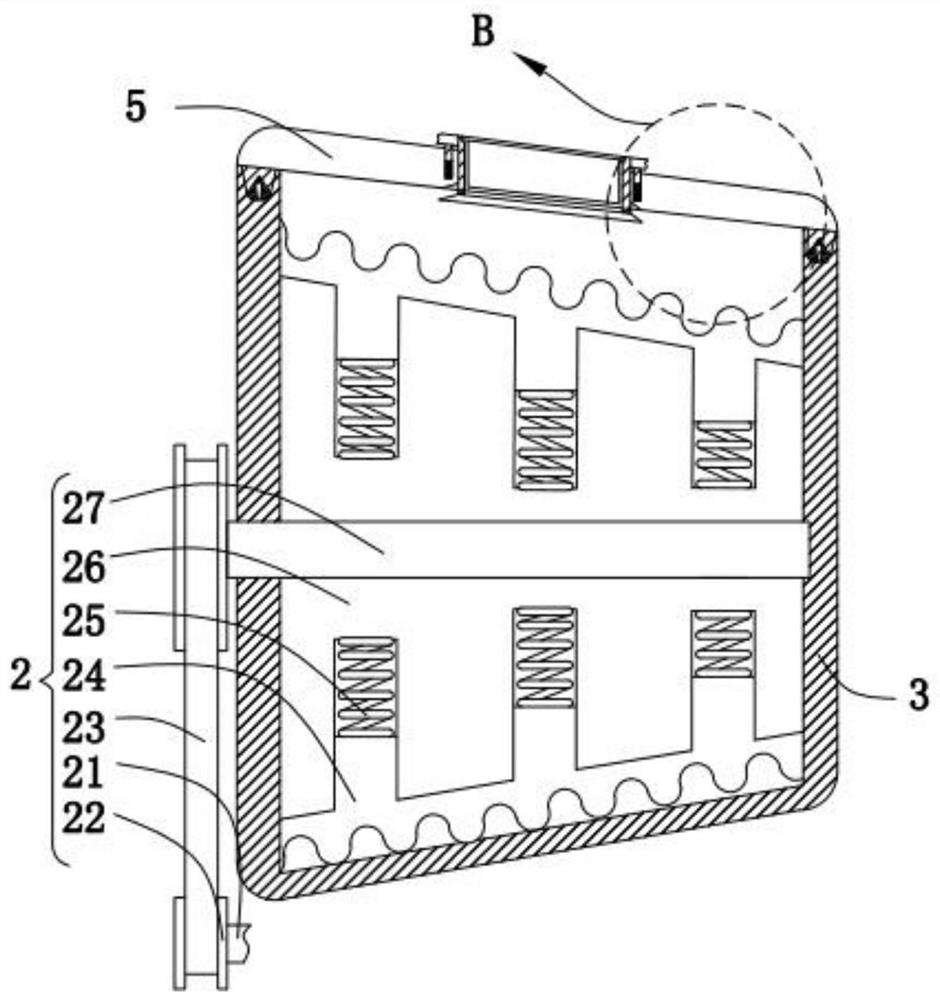

[0026] Such as figure 1 , figure 2 and image 3 As shown, an automatic brush plating repair device for an automobile engine connecting rod according to the present invention includes a diversion structure 1, a stirring structure 2, a storage tank 3, a liquid adding structure 4, an inspection structure 5, a fixing plate 6 and a filtering structure 7; the side wall of the fixed plate 6 for installing the device in a rectangular structure is provided with the storage box 3 for storing the electroplating solution with a square truss structure on the outside, and the inside of the storage box 3 is provided with a bottom It is a semi-circular frustum-shaped accommodation space; the bottom of the storage box 3 is provided with the guide structure 1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com