Air suction and blow cleaning device used in spinning frame

A cleaning device and air suction technology, which is applied in the direction of textiles and papermaking, can solve the problems of inability to clean roving slopes, high labor costs, low production quality and production efficiency, and achieve labor cost savings, improved production quality and production efficiency, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

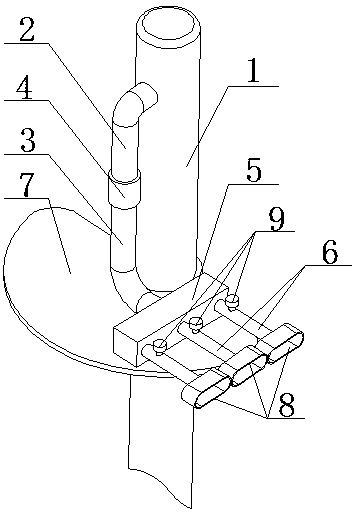

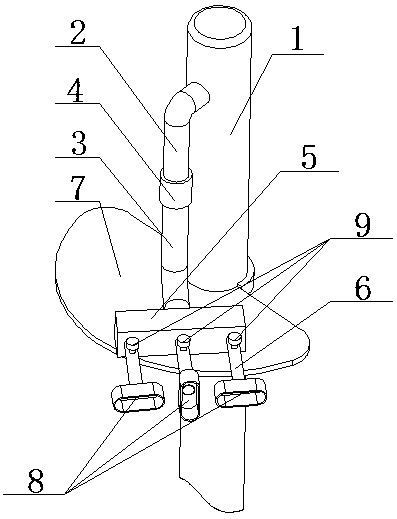

[0026] A blowing suction cleaning device for spinning frame of the present invention comprises blowing pipe 1 and blowing nozzle 2, blowing nozzle 2 is arranged on the outer wall of blowing pipe 1; the lower end of blowing nozzle 2 is provided with corrugated hose 3, blowing nozzle 2 There is a rotary sealing joint 4 between the corrugated hose 3, which is used for the corrugated hose 3 to rotate around the blowing nozzle 2; the lower end of the corrugated hose 3 is connected to the shunt bellows 5, and the other end of the shunt bellows 5 is connected to three air outlet pipes 6, The air outlet of the air outlet pipe 6 is movably provided with a nozzle 8 in the shape of a straight notch, and the nozzle 8 can rotate around the air outlet pipe 6; each air outlet pipe 6 is provided with a throttle valve 9 for controlling the outlet of the nozzle 8. The size of the air volume; the fan-shaped support frame 7 is movably socketed on the outer wall of the blowing pipe 1, and the split...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com