Anti-slip and drainage floor

A floor and anti-skid technology, applied in the field of drainage floor and anti-skid, can solve problems such as inconvenience of movement, increase construction difficulty and construction period, affect anti-skid effect, etc., and achieve the effect of increasing self-cleaning of drainage, improving anti-skid effect and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

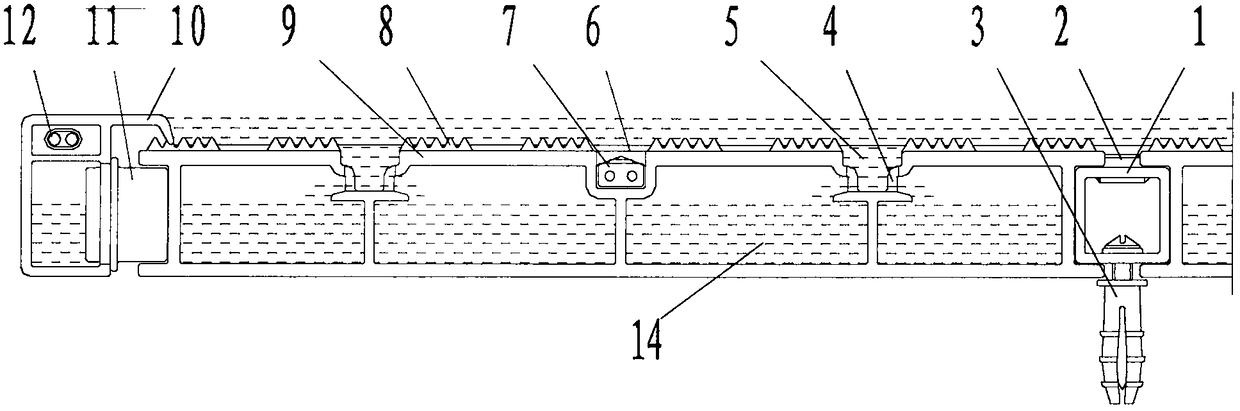

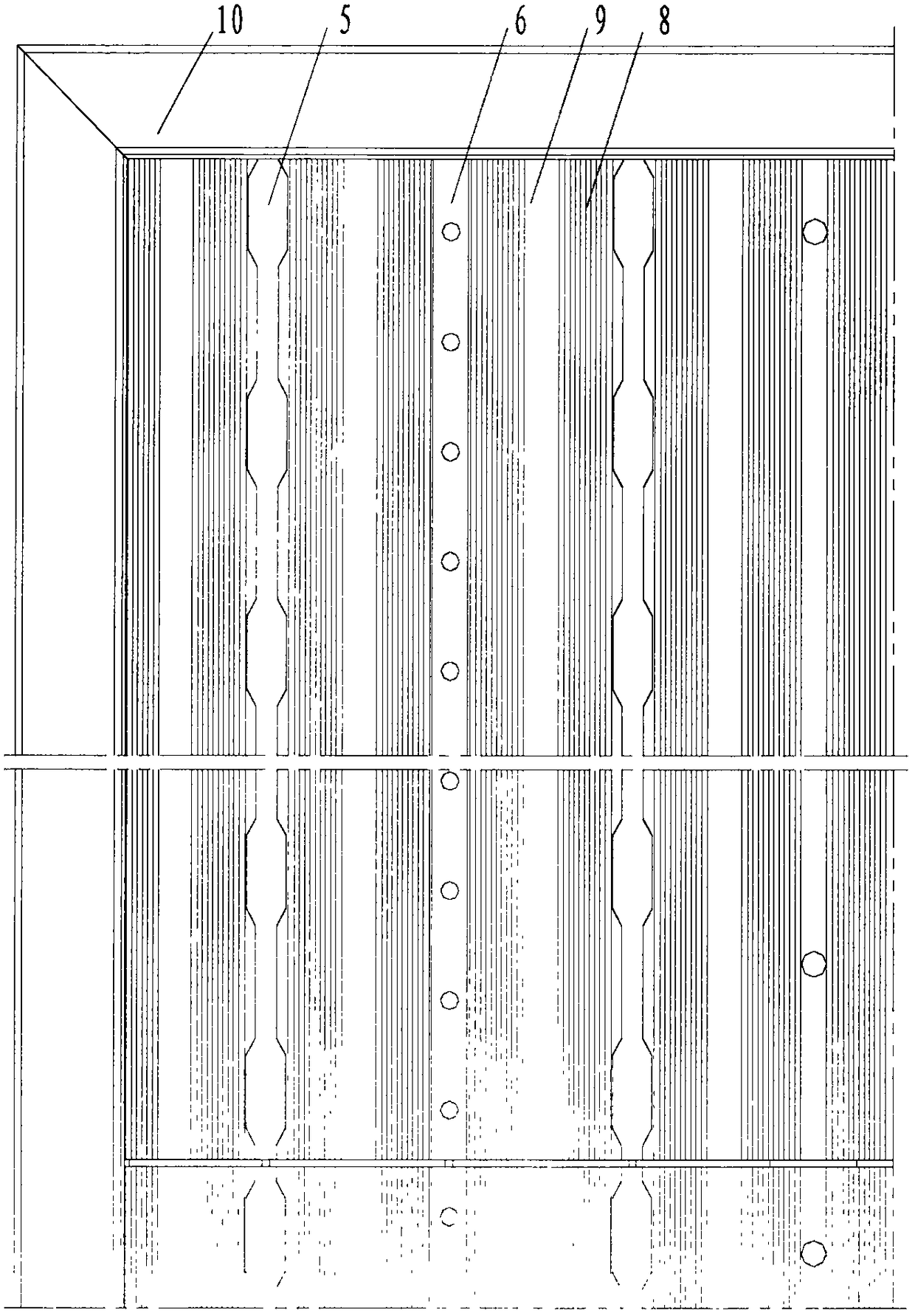

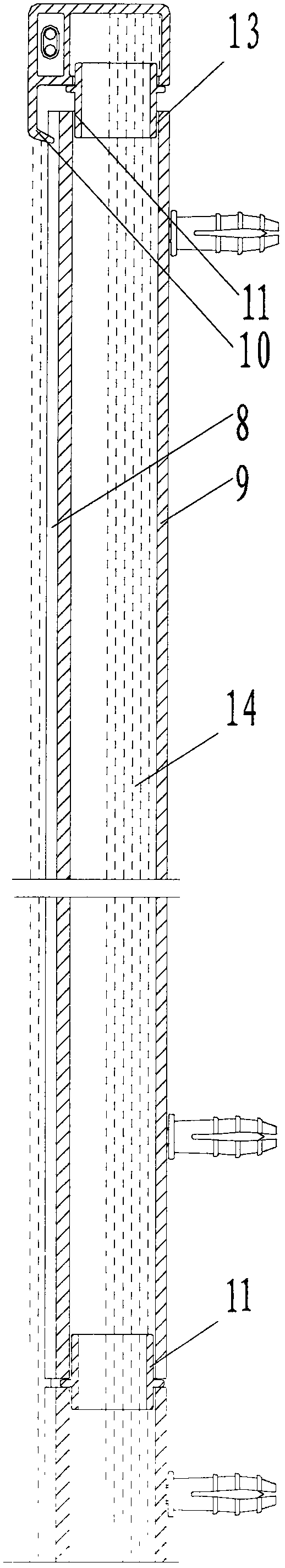

[0030] The present invention as figure 1 , 2 , 3, including the floor base material, edge protection profile 10, installation connector 1, light strip 7 and connection plug-in 11, the width direction of the floor base material is expanded by the installation connection profile 1 and fixedly installed through it, and the length direction is passed through the connection plug-in 11 is expanded, and the edge protection profile 10 is installed on the peripheral edge of the floor substrate.

[0031] Floor substrates such as Figure 5 As shown, it is composed of a floor profile 9, an anti-skid surface 8 and a lampshade 6. Several surface drainage grooves 5 and lampshades 6 are arranged on the upper surface of the floor profile 9, and several internal drainage grooves 14 are arranged inside. The light strip 7 is installed in the lampshade 6, and the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com