Transformer thermometer embedded groove replacing device

A technology for thermometers and transformers, which is applied in the field of replacement devices for embedded grooves in transformer thermometers, and can solve problems such as long working hours and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

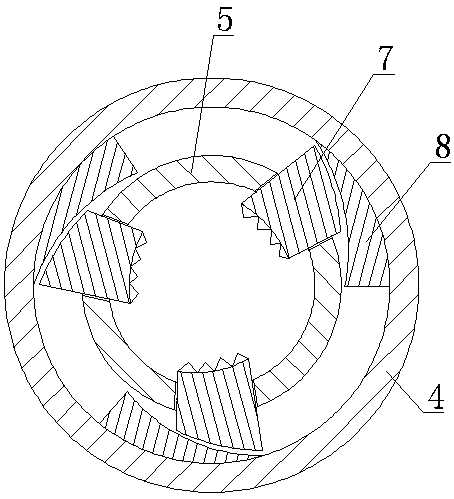

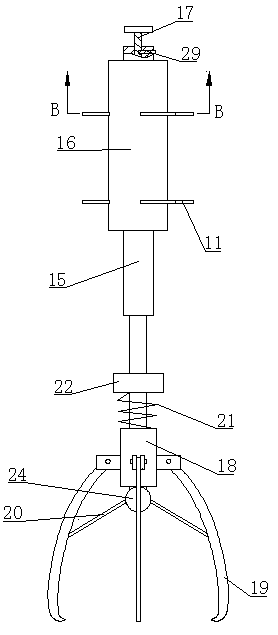

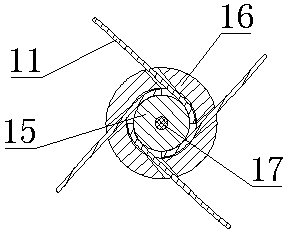

[0018] Such as figure 1 with figure 2 As shown, the replacement device for the embedded groove of the transformer thermometer includes a main body cover 1 with openings at both ends in the axial direction. For easy observation, the main body cover 1 can be made of a transparent material with suitable strength, which is convenient for observing the liquid level of the oil and the outer cylinder. s position. The lower end of the main body cover 1 is provided with a compression plate 2 perpendicular to the axis of the main body cover 1, and the upper surface of the compression plate 2 is provided with a fixed magnet that can be magnetically attracted to the transformer 25 to compress the compression plate 2 on the transformer. 3. In this embodiment, the compression plate 2 is in the shape of a step with a large bottom and a small top. The shape of the fixed magnet 3 is adapted to the shape of the compression plate 2. The compression plate 2 and the fixed magnet 3 of this struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com