Explosion-proof compact pressure switch and use method thereof

A pressure switch, explosion-proof technology, applied in electrical switches, electrical components, circuits, etc., can solve safety accidents, explosions and other problems, achieve the effect of safe and reliable use, wide application range, and avoid serious safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

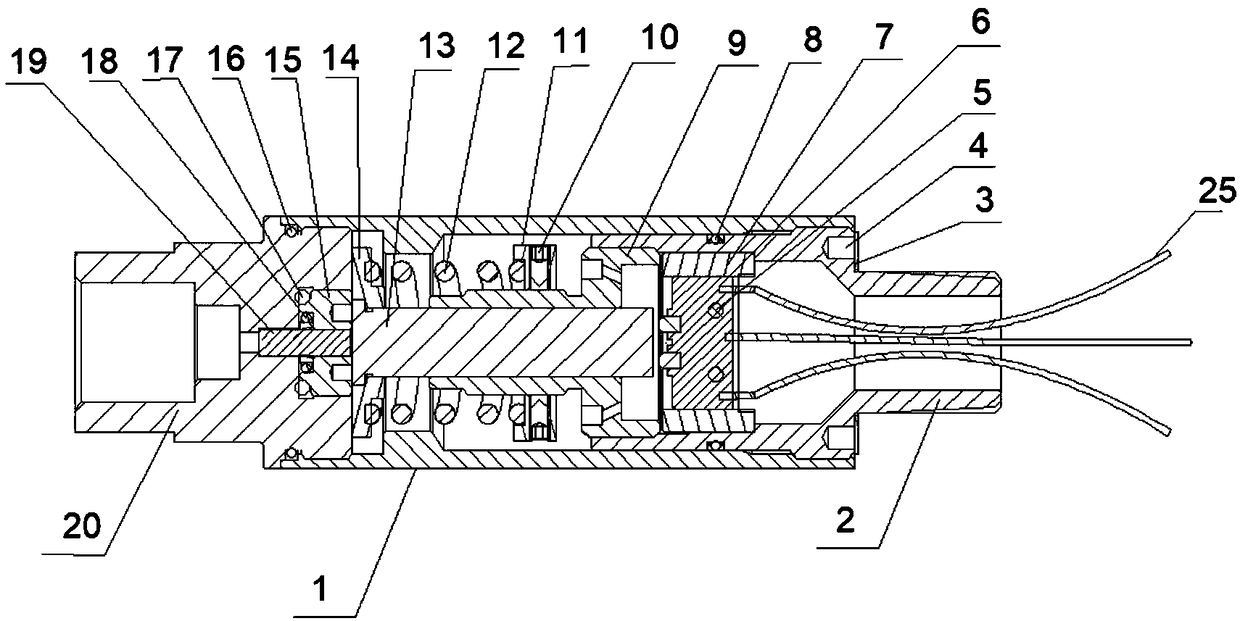

[0021] The magnetic differential pressure gauge of the present invention and its method of use are further described below in conjunction with the accompanying drawings and embodiments:

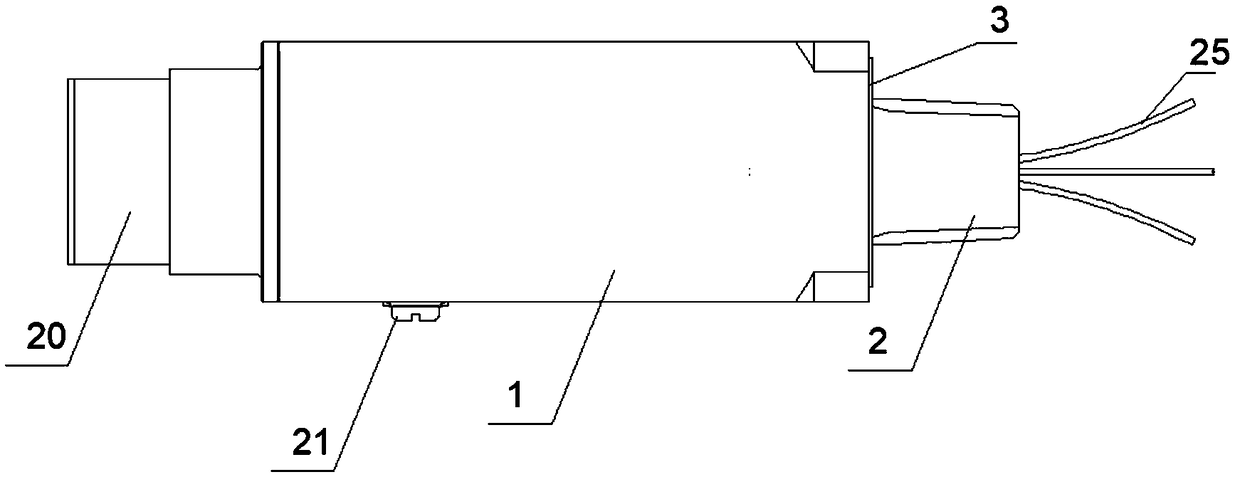

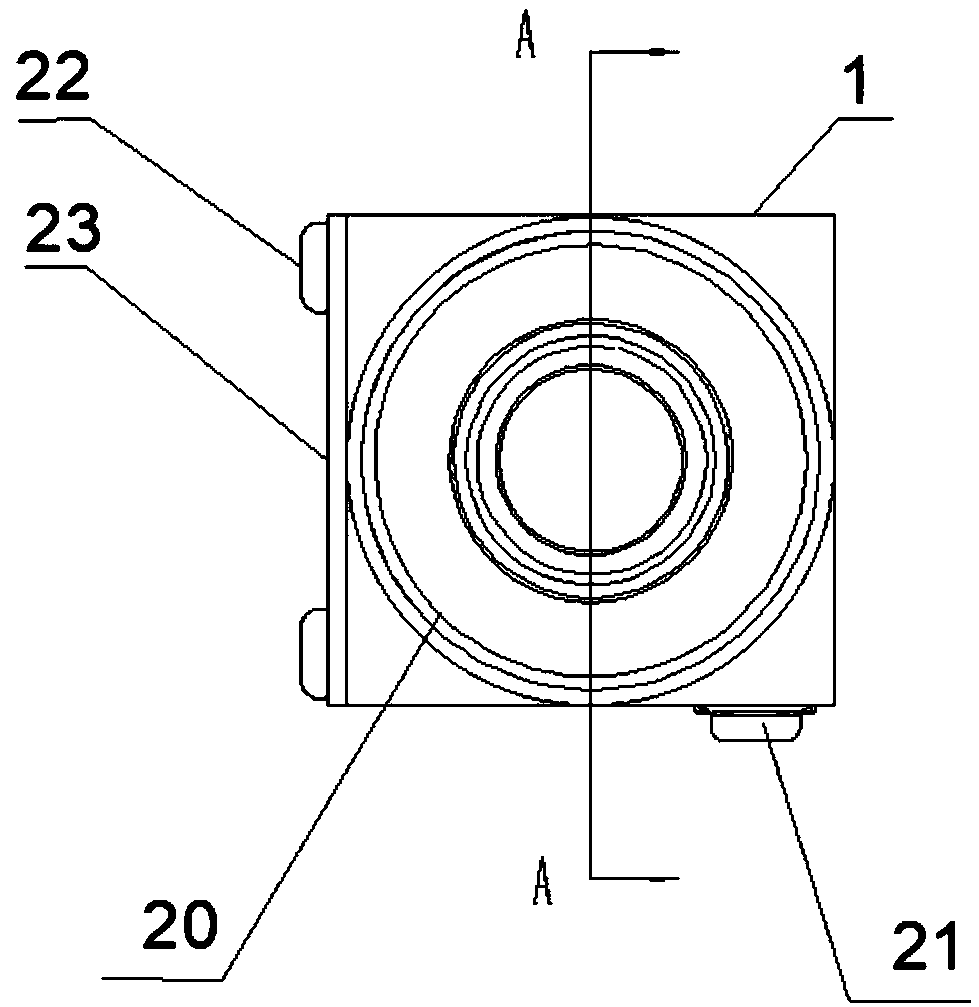

[0022] An explosion-proof compact pressure switch, including a housing 1, an electrical connector 2 and a process connector 20, the housing 1 is a cuboid with a cylindrical cavity inside, the left end of the housing 1 is connected to a pressure source The process joint 20 is threaded and sealed by the second sealing ring 16 , the right side of the process joint 20 and the inside of the housing 1 are provided with a cylindrical piston rod 19 , and the outside of the piston rod 19 is provided with a shaft sleeve 15 A third sealing ring 17 is provided between the bushing 15 and the process joint, a step seal 18 is provided between the bushing 15 and the piston rod 19, and a seal ring 18 is provided on the right side of the piston rod 19. Cylindrical push rod 13, the outer side of the push rod 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com