On-line detection method for siphon tube damage of steam drying cylinder

A technology of a steam dryer and a detection method, which is applied to the detection of the safety performance of the internal parts of the steam dryer and the online detection of the siphon damage of the steam dryer, which can solve the problems of energy utilization, increased operating costs, increased maintenance costs and downtime, Problems affecting the heat exchange effect of the steam drying cylinder, etc., to achieve the effects of reducing steam consumption, stabilizing the hand feeling of falling cloth, and improving the quality of dyeing and finishing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

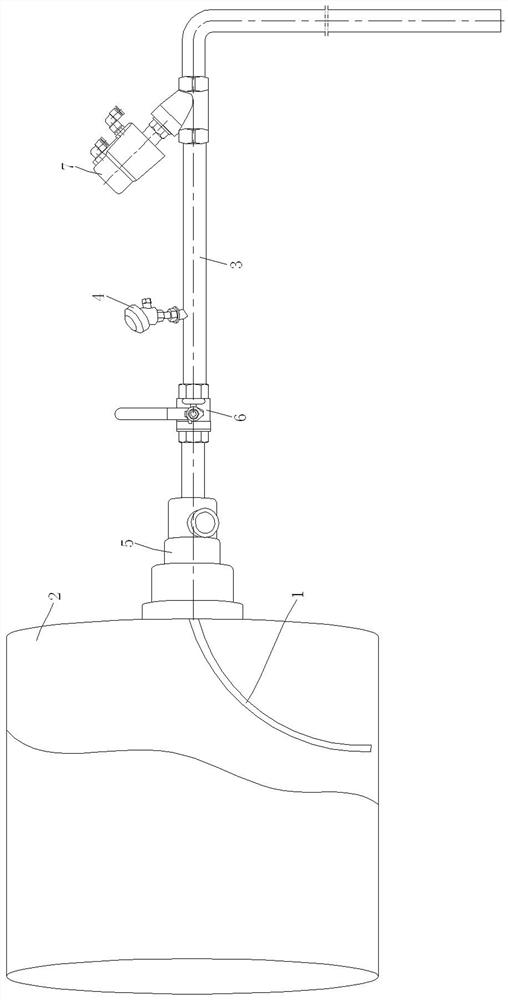

[0029] In order to find out whether the siphon tube 1 is damaged in time, prevent the condensed water in the steam dryer 2 from being discharged, and avoid various accidents, the present invention adopts an online detection method for the damage of the siphon tube of the steam dryer, see figure 1 , the siphon tube 1 is placed in the inner cavity of the steam drying drum 2, a drain pipe 3 is installed at one end of the steam dryer 2, and a pipe for detecting the temperature in the drain pipe 3 is installed on the pipeline of the drain pipe 3. The temperature sensor 4, the siphon pipe 1 is in fluid communication with the drain pipe 3, and the temperature sensor 4 is electrically connected with the steam dryer drying equipment or an independently installed electric controller. The electric controller is not shown in the figure. In the present invention Among them, a steam rotary joint 5, a manual shut-off valve 6 and a control valve 7, etc. can also be installed on the pipeline of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com