Waterproof USB socket and manufacturing method thereof

A technology of waterproof glue and connectors, which is applied to the assembly/disassembly of the base/housing, contact parts, electrical components, etc., and can solve the problems of being unable to achieve waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

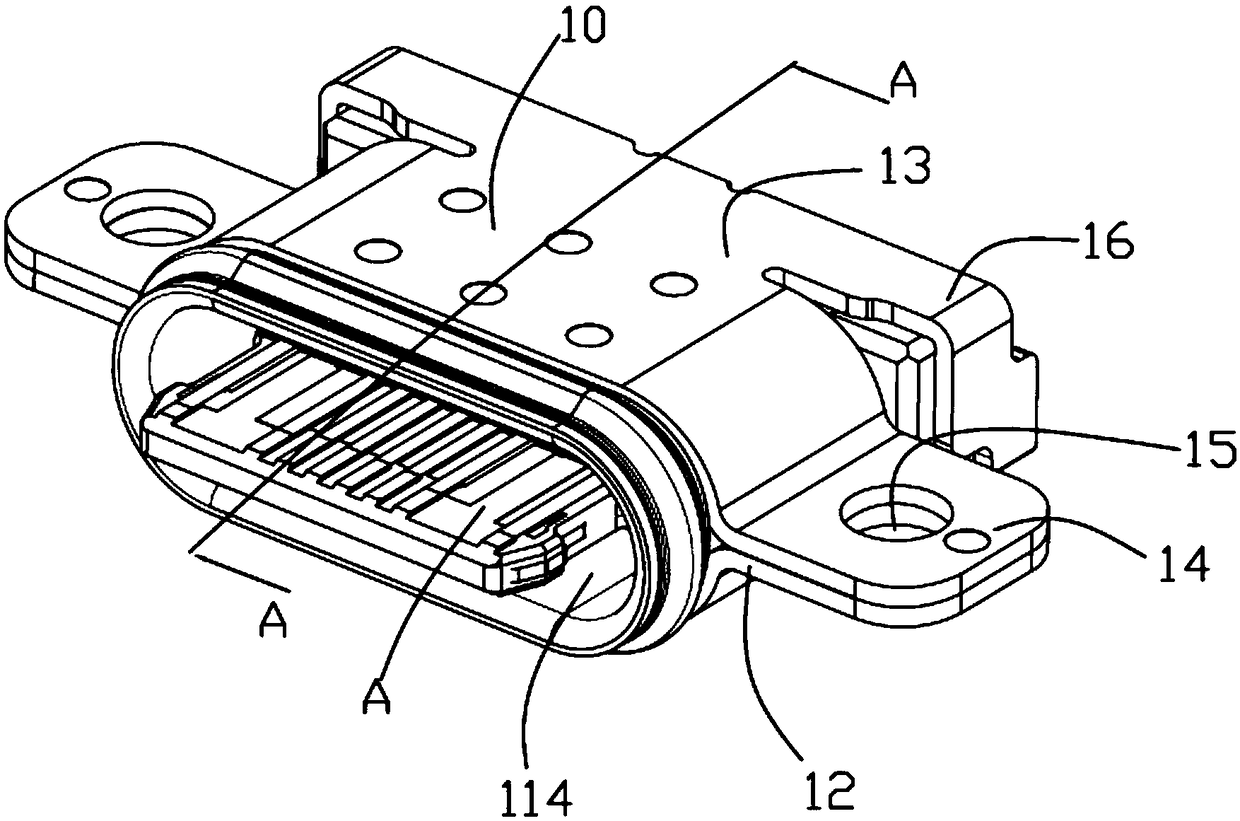

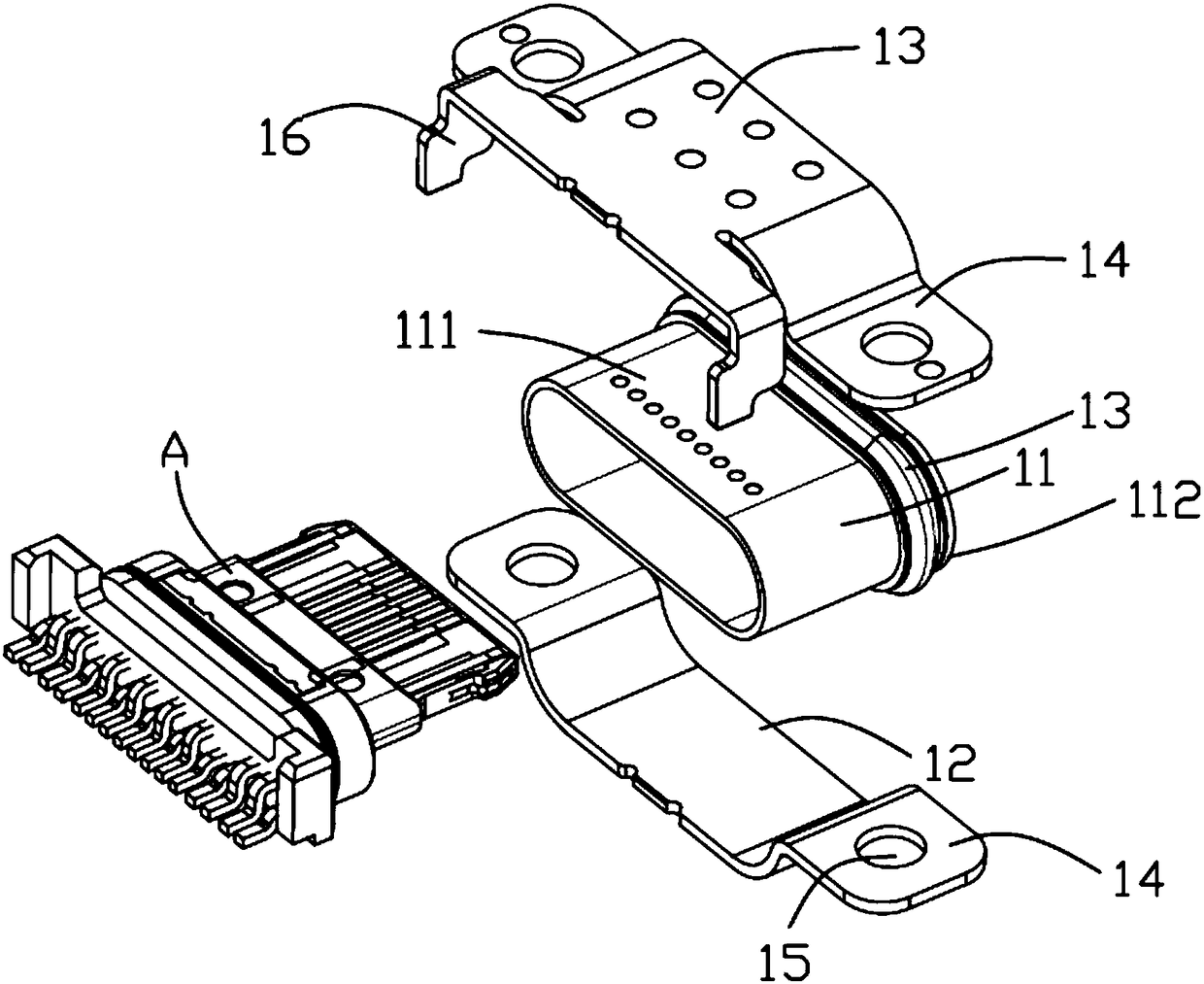

[0036] see Figure 1 to Figure 9 As shown, the waterproof USB socket of the present application includes a connector A, a metal shell 10 sleeved on the periphery of the connector A, waterproof glue filled in the tail of the connector A, and a metal shell sleeved on the metal shell. 10 the waterproof ring 113 of front end portion.

[0037] The connector A includes terminal groups 20 , 30 , a metal middle plate 70 , and an insulating body 40 integrally forming the terminal groups 20 , 30 and the metal middle plate 70 . The insulating body 40 includes a base portion 42 , a step portion 43 extending forward from the base portion 42 , and an abutting portion 41 extending forward from the step portion 43 . Parts of the terminal groups 20 , 30 are exposed on the upper and / or lower surfaces of the docking portion 41 to be in electrical contact with the docking connector.

[0038] The metal shell 10 includes a metal inner shell 11 sleeved on the periphery of the insulating body 40 , ...

Embodiment 2

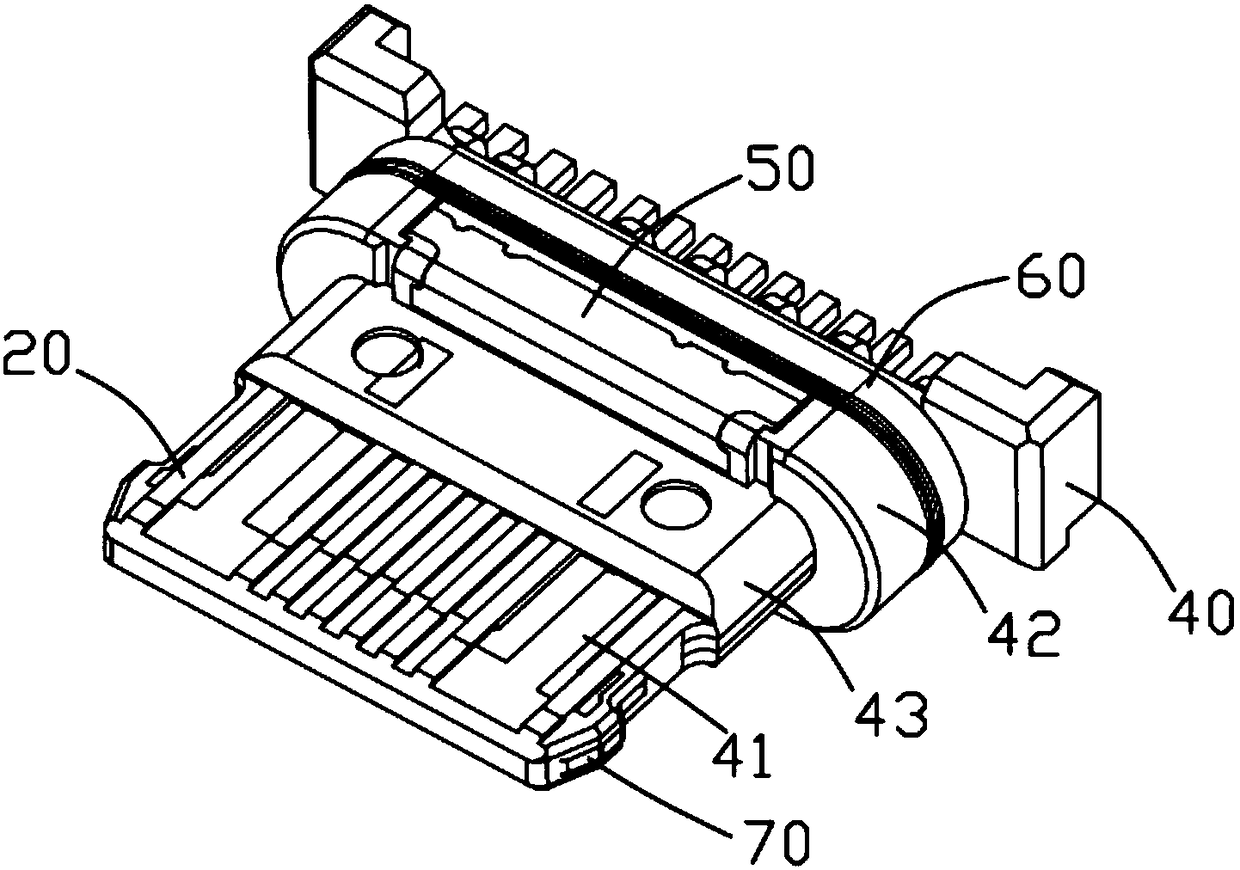

[0055] see Figure 10 to Figure 13 As shown, the first embedded portion 54 of the blocking member 50 in this embodiment further includes a barb 543 bent and extended downward from the horizontal portion 542 . The second embedding portion 53 further includes a locking portion 531 bent vertically from the end of the second embedding portion 53 . The resisting portion 52 of the blocking member 50 also defines a positioning notch 56 .

[0056] In the first embodiment, the first and second plastic bodies 44 , 45 correspond to the accommodating groove 441 at the position of the base part 42 , and in the second embodiment, the accommodating platform 441 is used. The removal part 442 on the lateral outer side of the receiving platform 441 is provided with a card hole 443, and the rear end edge of the receiving platform 441 is provided with a card slot 444 for inserting the third embedded part 55, and the front end surface of the receiving platform 441 A positioning block 445 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com