Leather-adhering velcro tape mounting mechanism realizing automatic grasping of velcro tapes

A technology of installation mechanism and Velcro, applied in the direction of tools for sewing clothes, etc., can solve the problems of low efficiency and trouble, achieve high efficiency, ensure adhesion effect, and ensure the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

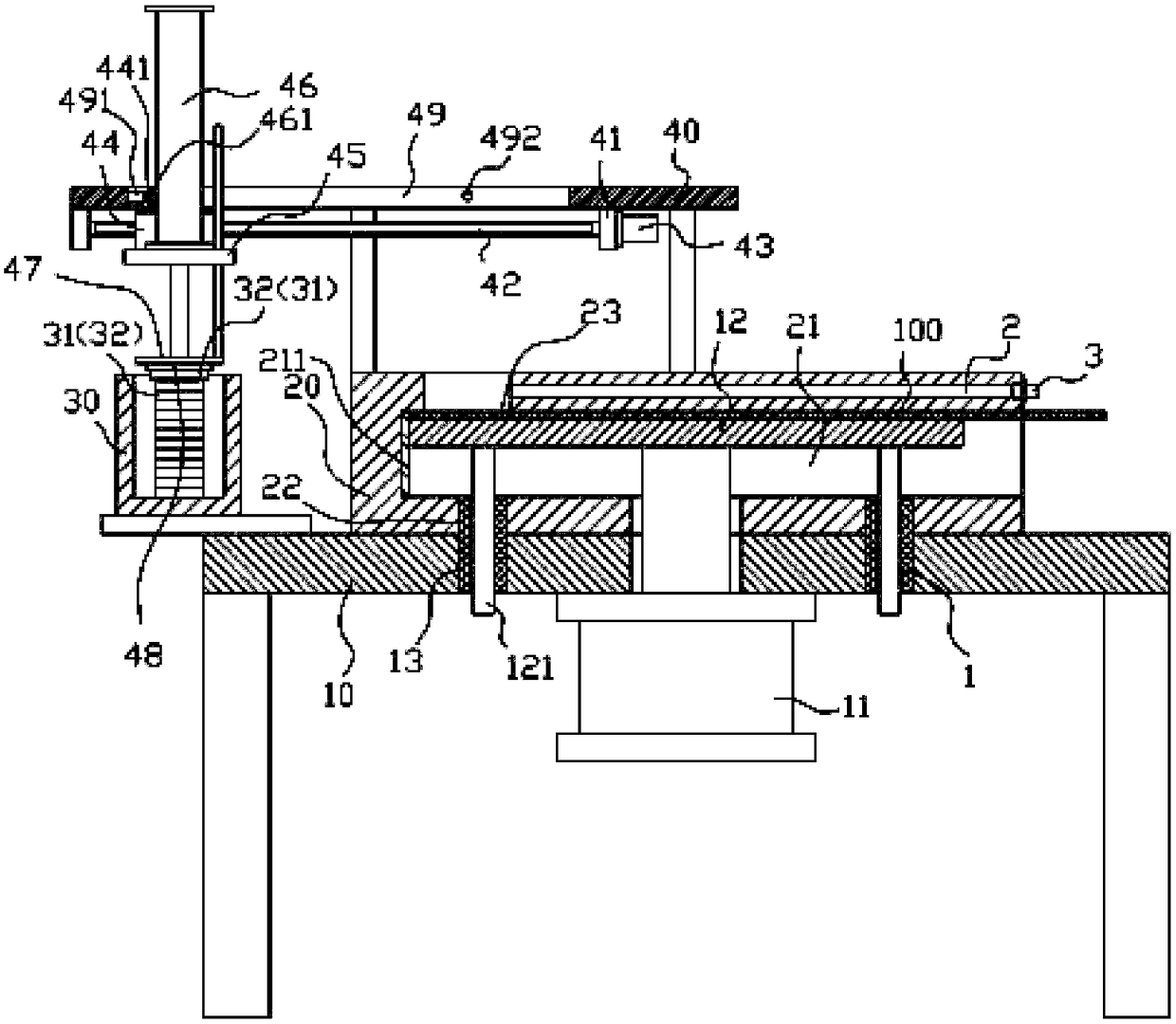

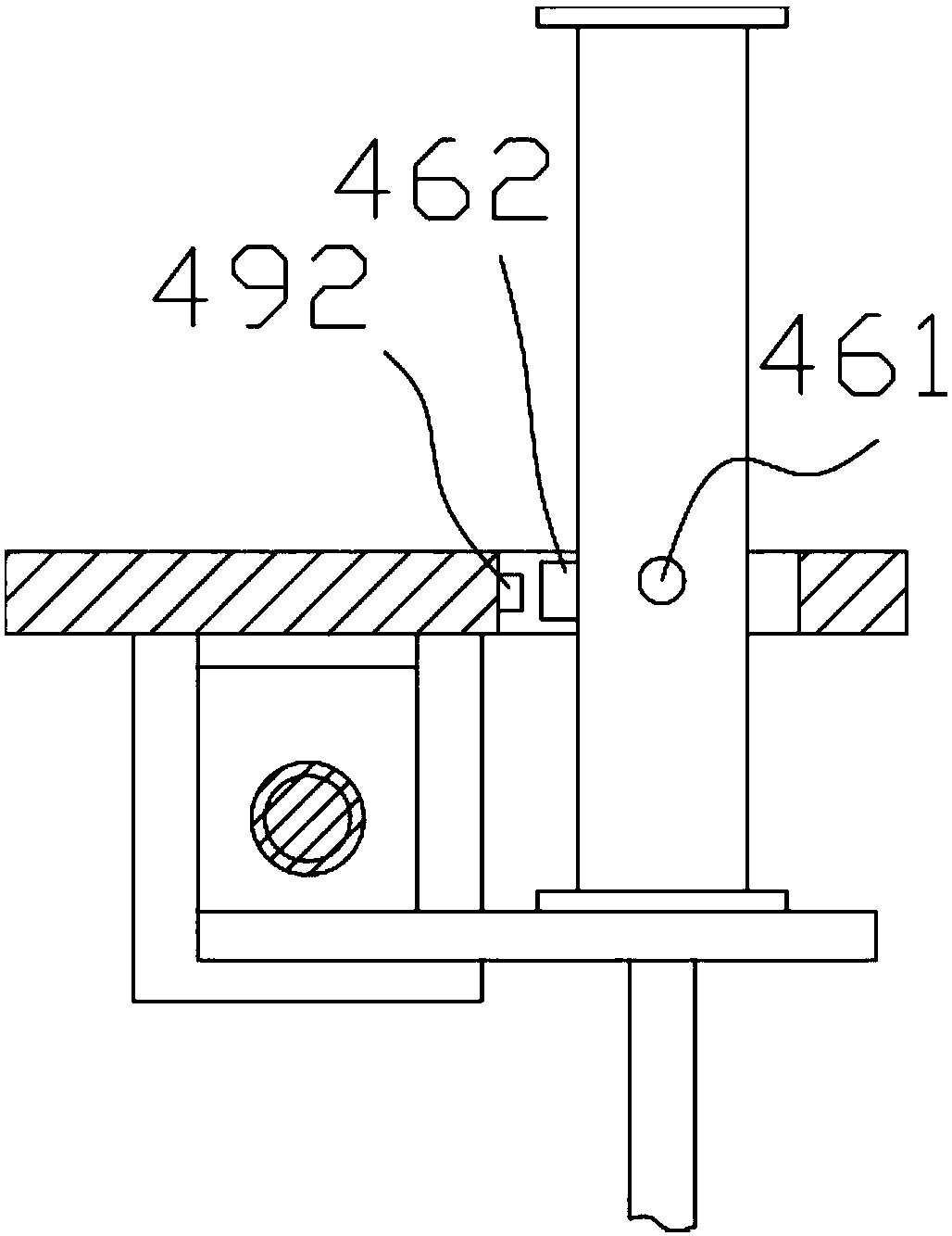

[0018] Example: see Figure 1 to Figure 2 Shown, a kind of Velcro automatically grasps the leather material adhesion Velcro installation mechanism, comprises frame 10, and the middle part top surface of the top plate of described frame 10 is fixed with fixing block 20, and the left side of the top plate of frame 10 The side top surface is fixed with a Velcro discharge tank 30, and the Velcro male sticker 31 or the Velcro female sticker 32 to be adhered to be stacked up and down is placed in the Velcro discharge tank 30, and the top surface of the fixed block 20 is installed An upper support frame 40 is fixed, and the left end of the top plate of the upper support frame 40 is above the Velcro discharge tank body 30. The left and right ends of the top plate of the upper support frame 40 are fixed with a vertical plate 41, and the two sides of the horizontal screw rod 42 Both ends are hinged on two vertical plates 41 through bearings, and a mobile motor 43 is fixed on the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com