Loading automobile field maintenance tool placement box

A technology for repairing tools and placing boxes, which is applied to tool storage devices, vehicle maintenance/repair, manufacturing tools, etc., can solve the problems of not being able to maintain tools in classified placement, taking a lot of time to find, and inconvenient to find quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

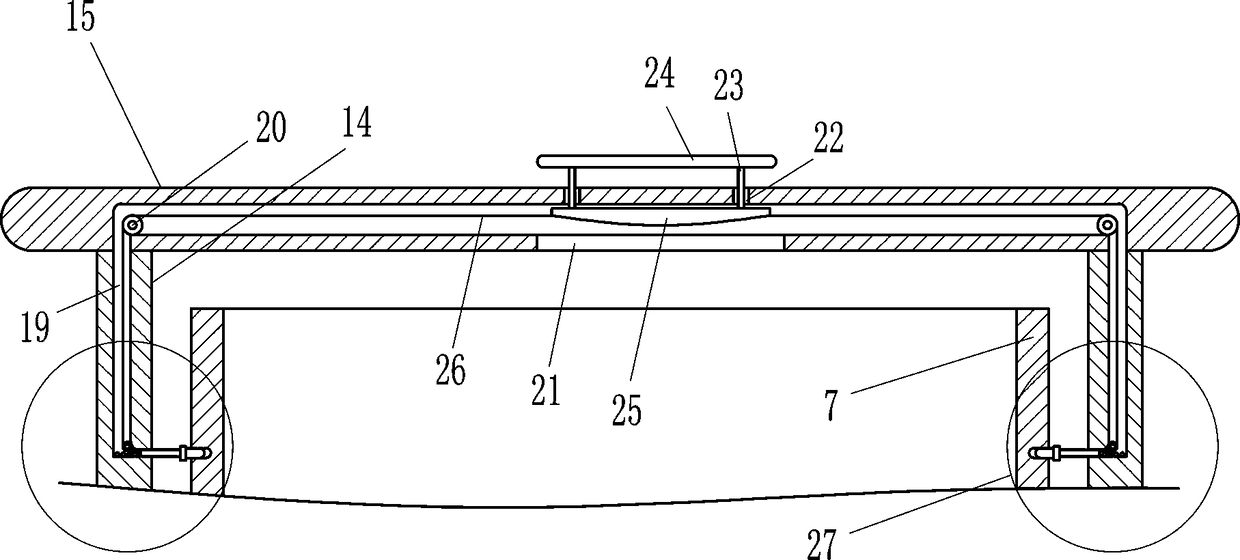

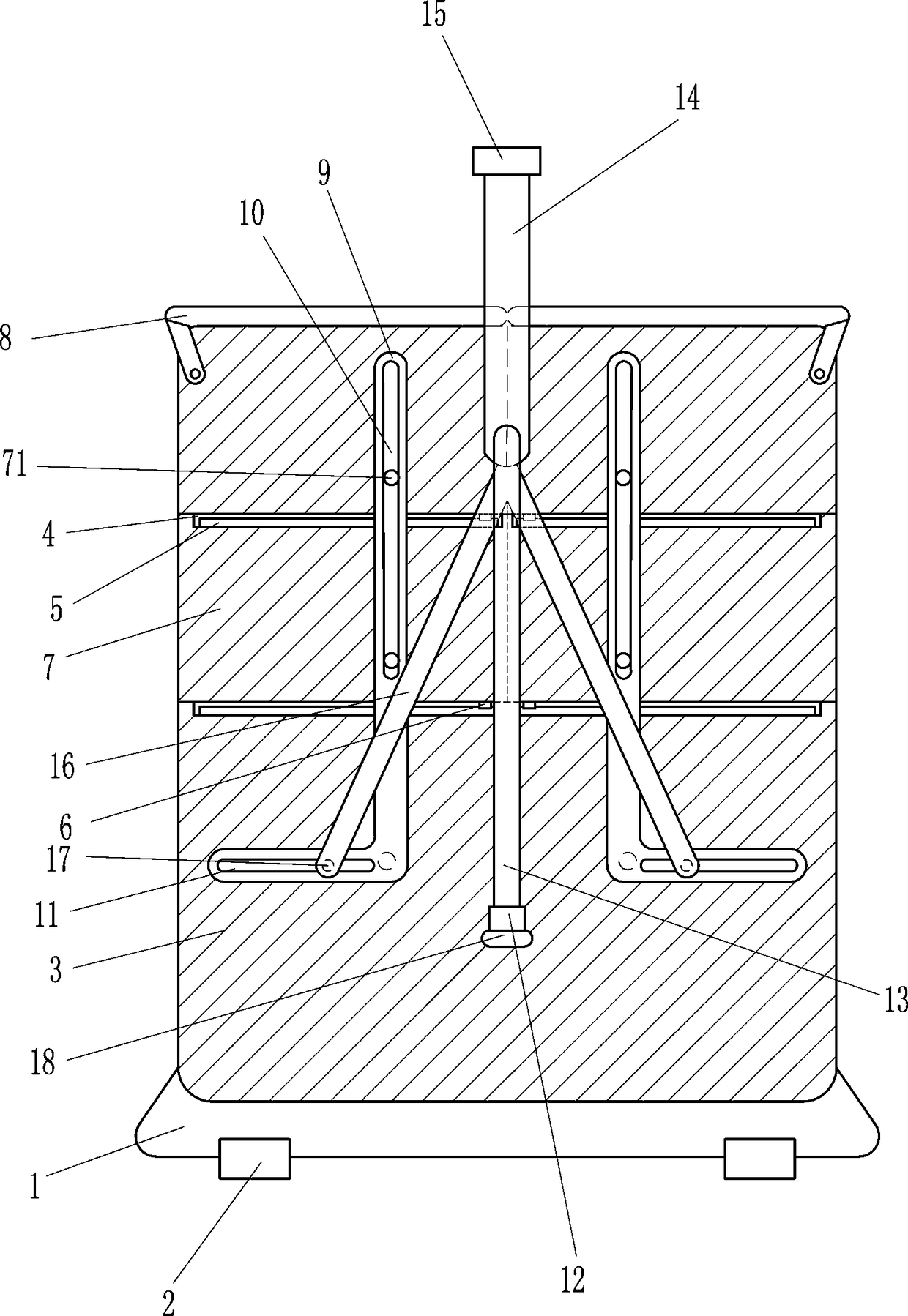

[0020] A kind of storage box for field maintenance tools for trucks, such as Figure 1-6As shown, it includes base 1, wheels 2, large placement frame 3, slide rail 5, slider 6, small placement frame 7, first sliding shaft 71, cover plate 8, L-shaped rod 9, guide sleeve 12, guide rod 13. The first connecting rod 14, pull rod 15, V-shaped rod 16, second sliding shaft 17 and stopper 18, the left and right sides of the front and rear sides of the base 1 are embedded with wheels 2, and the top of the base 1 is provided with a large Frame 3, the front and rear sides of the top of the large placement frame 3 are provided with installation grooves 4, and the left and right sides in the installation groove 4 are provided with slide rails 5, and slide rails 5 are slidingly provided with slide blocks 6, and the left and right sides The top of the slide block 6 is provided with a small placement frame 7, and the front and rear sides of the top of the small placement frame 7 are provided w...

Embodiment 2

[0022] A kind of storage box for field maintenance tools for trucks, such as Figure 1-6 As shown, it includes base 1, wheels 2, large placement frame 3, slide rail 5, slider 6, small placement frame 7, first sliding shaft 71, cover plate 8, L-shaped rod 9, guide sleeve 12, guide rod 13. The first connecting rod 14, pull rod 15, V-shaped rod 16, second sliding shaft 17 and stopper 18, the left and right sides of the front and rear sides of the base 1 are embedded with wheels 2, and the top of the base 1 is provided with a large Frame 3, the front and rear sides of the top of the large placement frame 3 are provided with installation grooves 4, and the left and right sides in the installation groove 4 are provided with slide rails 5, and slide rails 5 are slidingly provided with slide blocks 6, and the left and right sides The top of the slide block 6 is provided with a small placement frame 7, and the front and rear sides of the top of the small placement frame 7 are provided ...

Embodiment 3

[0025] A kind of storage box for field maintenance tools for trucks, such as Figure 1-6 As shown, it includes base 1, wheels 2, large placement frame 3, slide rail 5, slider 6, small placement frame 7, first sliding shaft 71, cover plate 8, L-shaped rod 9, guide sleeve 12, guide rod 13. The first connecting rod 14, pull rod 15, V-shaped rod 16, second sliding shaft 17 and stopper 18, the left and right sides of the front and rear sides of the base 1 are embedded with wheels 2, and the top of the base 1 is provided with a large Frame 3, the front and rear sides of the top of the large placement frame 3 are provided with installation grooves 4, and the left and right sides in the installation groove 4 are provided with slide rails 5, and slide rails 5 are slidingly provided with slide blocks 6, and the left and right sides The top of the slide block 6 is provided with a small placement frame 7, and the front and rear sides of the top of the small placement frame 7 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com