Preparation method of nucleating agent applied to modification and refinement of hypoeutectic aluminum-silicon alloy

An aluminum-silicon alloy, modification and refinement technology, which is applied in the field of aluminum-based alloys, can solve the problems that modification treatment and refinement treatment cannot be carried out at the same time, the refinement effect of hypoeutectic aluminum-silicon alloy is not obvious, and the degree of particle dispersion is not ideal. , to achieve excellent refinement effect, good metamorphic effect, and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

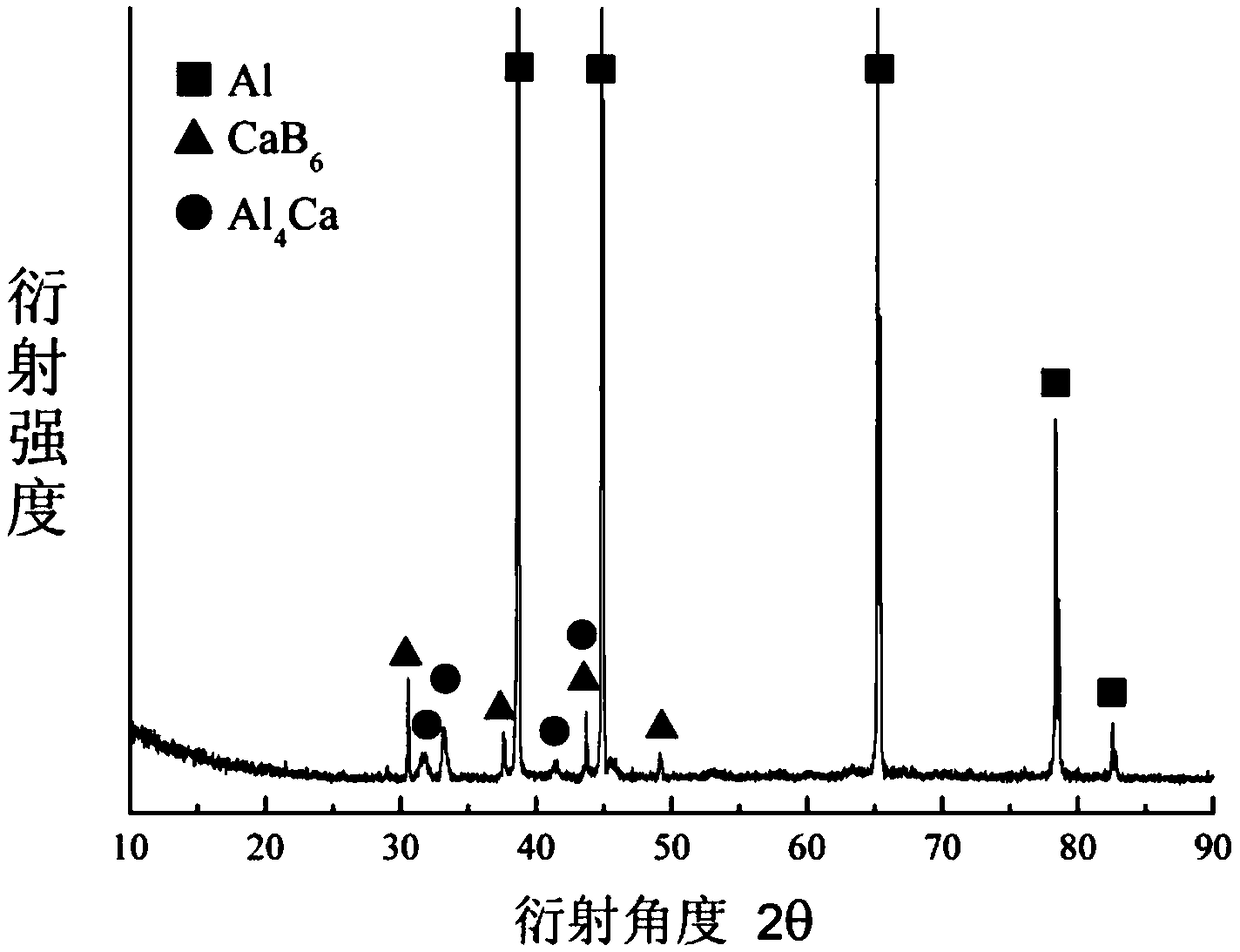

Embodiment 1

[0043] First step, ingredients:

[0044] Take the commercially available Al-B master alloy and the commercially available Al-Ca master alloy of the required amount, the mass percentage of the B element content in the commercially available Al-B master alloy is 3%, and the commercially available Al-Ca master alloy The mass percentage of Ca element content is 10%, carries out batching according to the mass ratio of Al-B master alloy: Al-Ca master alloy=5:2.5;

[0045] The second step is to prepare bulk Al-B-Ca master alloy:

[0046] Put the raw materials Al-B master alloy and Al-Ca master alloy weighed in the first step above into the copper crucible of WK-II vacuum arc melting furnace for melting, the vacuum degree is 4×10 -3 Pa, then filled with argon, the argon pressure in the furnace is 0.5MPa, the whole melting process needs to be under the protection of argon, and the copper crucible needs to be cooled by circulating water, adjust the current to control the melting temper...

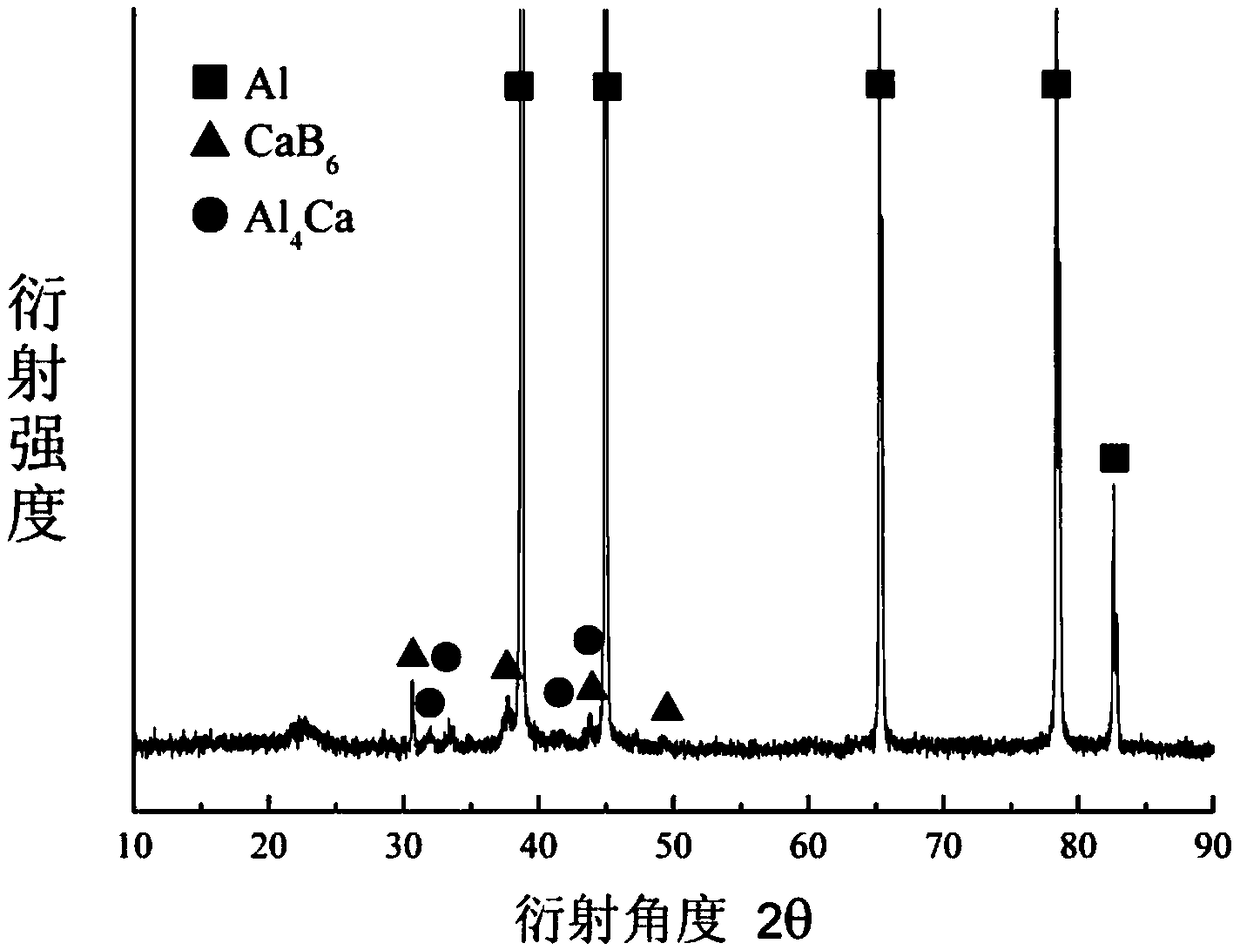

Embodiment 2

[0050] First step, ingredients:

[0051] Take the commercially available Al-B master alloy and the commercially available Al-Ca master alloy of the required amount, the mass percentage of the B element content in the commercially available Al-B master alloy is 2.5%, and the commercially available Al-Ca master alloy The mass percent of Ca element content is 12%, carries out batching according to the mass ratio of Al-B master alloy: Al-Ca master alloy=5:1;

[0052] The second step is to prepare bulk Al-B-Ca master alloy:

[0053] Put the raw materials Al-B master alloy and Al-Ca master alloy weighed in the first step above into the copper crucible of WK-II vacuum arc melting furnace for melting, the vacuum degree is 2×10 -3 Pa, then filled with argon, the argon pressure in the furnace is 0.4MPa, the whole melting process needs to be under the protection of argon, and the copper crucible needs to be cooled by circulating water, adjust the current to control the melting temperatu...

Embodiment 3

[0057] First step, ingredients:

[0058] Take the commercially available Al-B master alloy and the commercially available Al-Ca master alloy of required consumption, the mass percentage of B element content in this commercially available Al-B master alloy is 2%, in this commercially buy Al-Ca master alloy The mass percent of Ca element content is 8%, carries out batching according to the mass ratio of Al-B master alloy: Al-Ca master alloy=5:3;

[0059] The second step is to prepare bulk Al-B-Ca master alloy:

[0060] Put the raw materials Al-B master alloy and Al-Ca master alloy weighed in the first step above into the copper crucible of WK-II vacuum arc melting furnace for melting, the vacuum degree is 5×10 -3 Pa, and then filled with argon, the argon pressure in the furnace is 0.45MPa, the whole melting process needs to be under the protection of argon, and the copper crucible needs to be cooled by circulating water, adjust the current to control the melting temperature, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap