Bit block for PDC (polycrystalline diamond compact) bits

A drill body and drill bit technology, applied in construction and other directions, can solve problems affecting drilling speed and downhole safety, and achieve the effect of improving mud inclusion and increasing cross-sectional size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

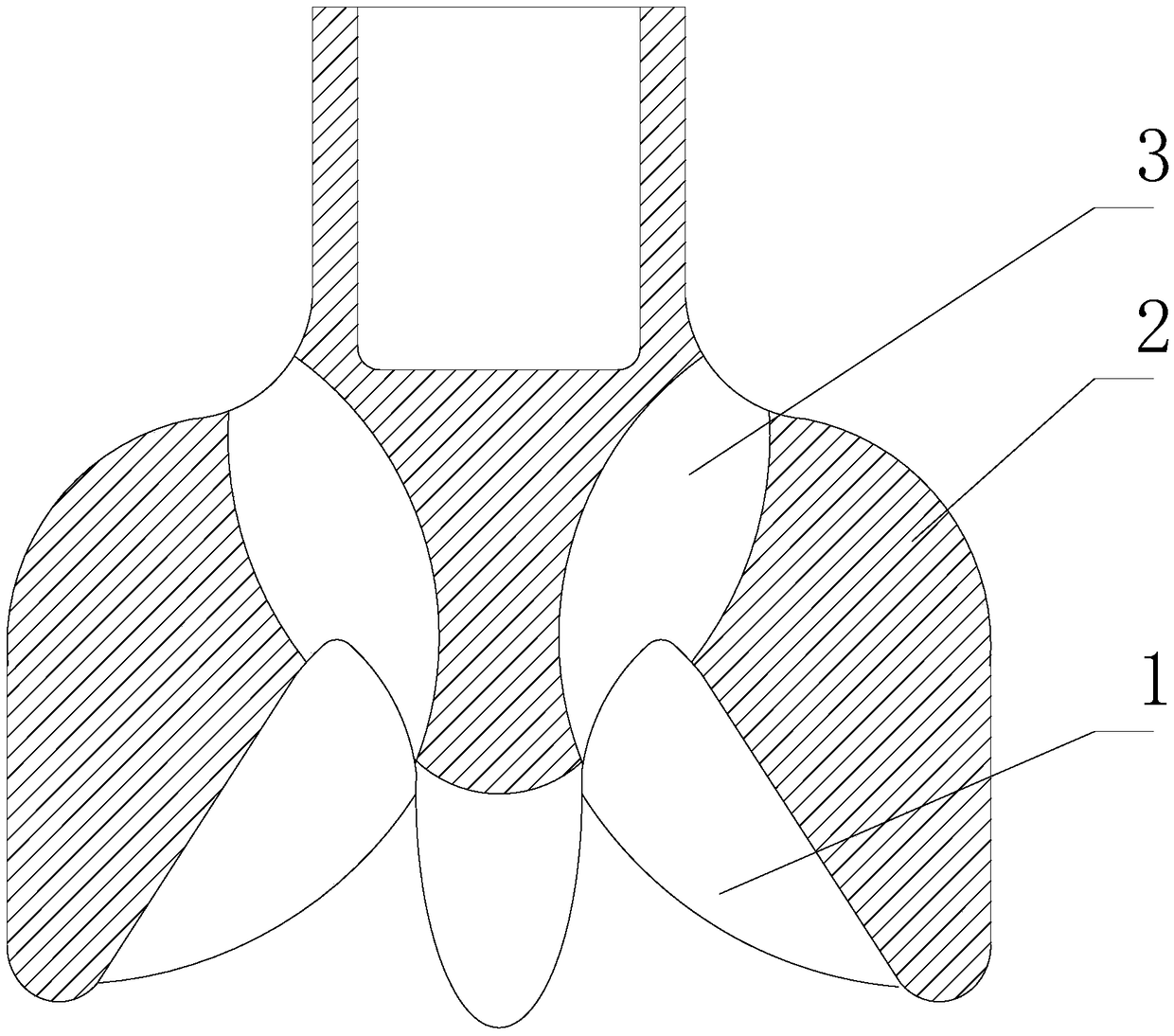

[0019] Such as figure 1 As shown, the drill body for the PDC drill bit includes a drill body body and a plurality of blades 2 installed on the drill body body. The blades 2 are uniformly distributed in a ring relative to the axis of the drill bit, and The bottom groove 1 located at the lower end of the drill body body is surrounded between the lower ends, and also includes a plurality of mud discharge holes 3 provided on the drill body body, the lower ends of the mud discharge holes 3 are connected to the top of the bottom groove 1, the The upper end of the mud discharge hole 3 extends to the side position of the upper end of the drill bit body.

[0020] In this scheme, the blade 2 is a part directly used on the drill body to interact with rock and soil to realize drilling. In this scheme, a plurality of blades 2 are evenly distributed in a ring and form a bottom at the lower end of the drill body. Groove 1, during the working process of the drill bit, the drilling mud produc...

Embodiment 2

[0022] Such as figure 1 As shown, this embodiment is further limited on the basis of embodiment 1: in order to avoid stress concentration on the drill bit, it is set as follows: the side surface of the drill bit body is a smooth surface.

[0023] In order to make the force on each point of the drill bit more uniform during the working process, a plurality of mud discharge holes 3 are uniformly distributed in a circular relationship with respect to the axis of the drill bit.

[0024] In order to enable the drill bit to use hydraulic equipment to realize drilling mud flushing, it is set as follows: the drill bit body is also provided with a flushing water flow channel.

[0025] As an implementation method that can use the drill pipe as the water injection flow channel, the inlet end of the flushing water flow channel is located at the upper end of the drill bit body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com