Track board vibration-guiding vibration-isolating vibration absorber based on particle damping and phononic crystal

A phononic crystal and particle damping technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of the influence of the band gap characteristics of phononic crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

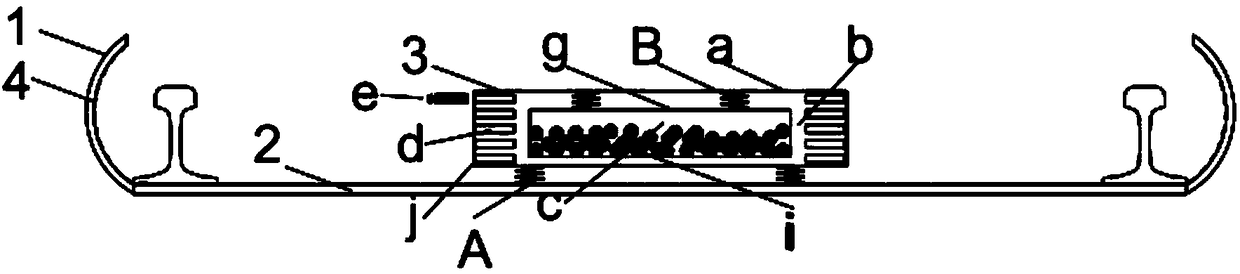

[0029] Specific implementation mode one: combine Figure 1-Figure 5 Explain that a track plate vibration-guiding vibration-isolation absorber based on particle damping and phononic crystals in this embodiment includes a sound insulation plate 1, a sound guide plate 2, a vibration-absorbing box 3, and a localized phononic crystal scatterer 4 .

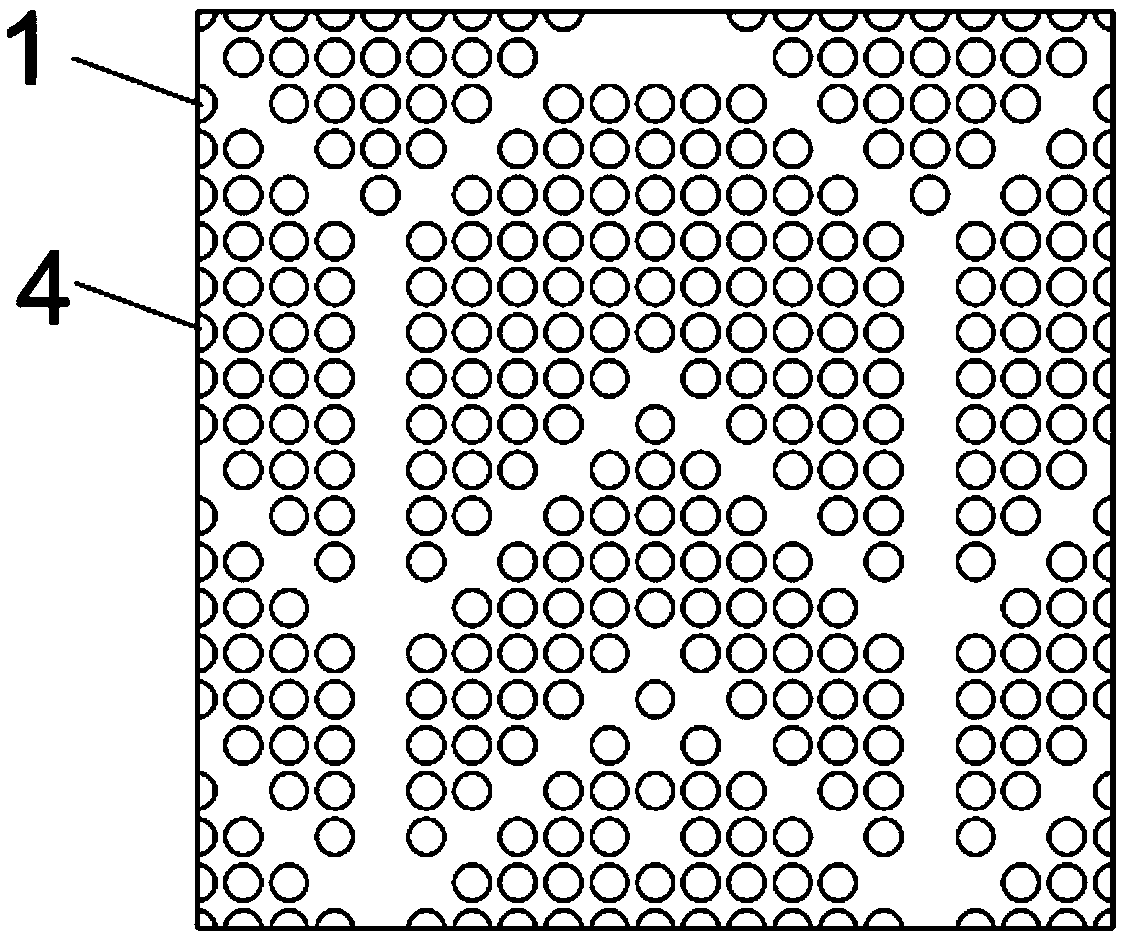

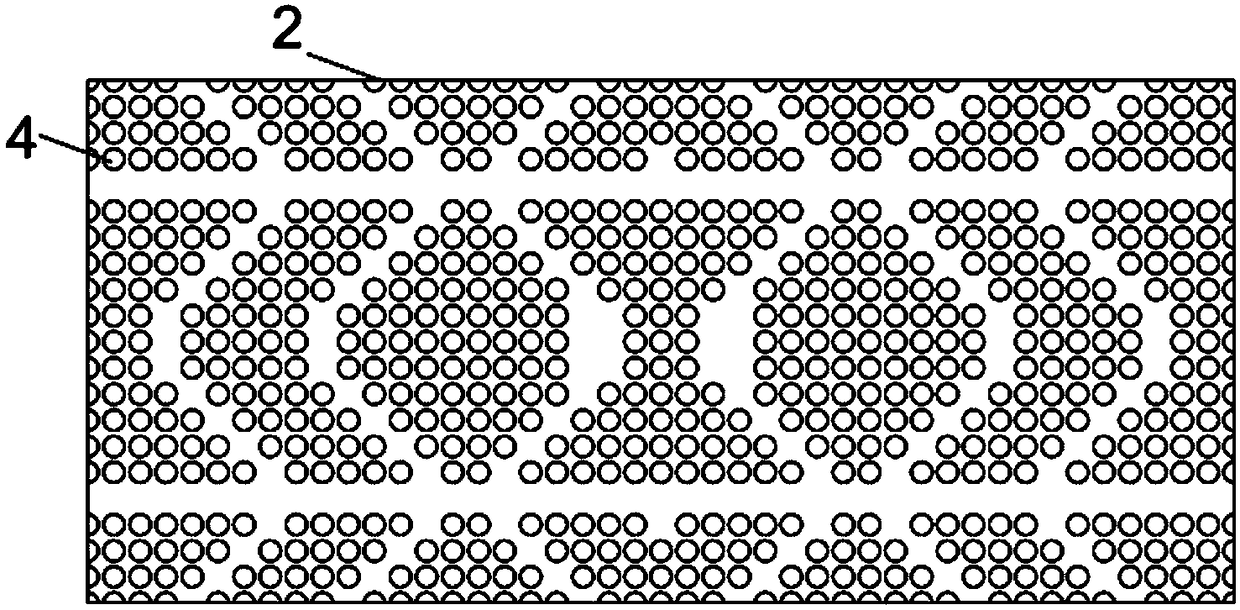

[0030] Wherein, the sound guide plate 2 is installed under the track, and the vibration-absorbing box 3 is arranged on the sound guide plate 2 and between the two tracks through the spring A. The sound insulation panel 1 is connected to the edge of the sound panel 2 . The localized phononic crystal scatterer 4 is fixed on the inner side of the sound insulation board 1 and the upper side of the sound guide board 2 .

[0031] The localized phonon crystal scatterers 4 on the sound insulation board 1 are arranged in such a way that, compared with the uniform distribution, it removes some localized phonon crystal scatterers 4 and removes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com