Oil fume exhaust ventilator and chassis assembly thereof

A range hood and casing technology, which is applied in the field of kitchen utensils, can solve problems such as easy bumps and large volume of side suction range hoods, and achieve the effects of improving smoking efficiency, improving smoke collection effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

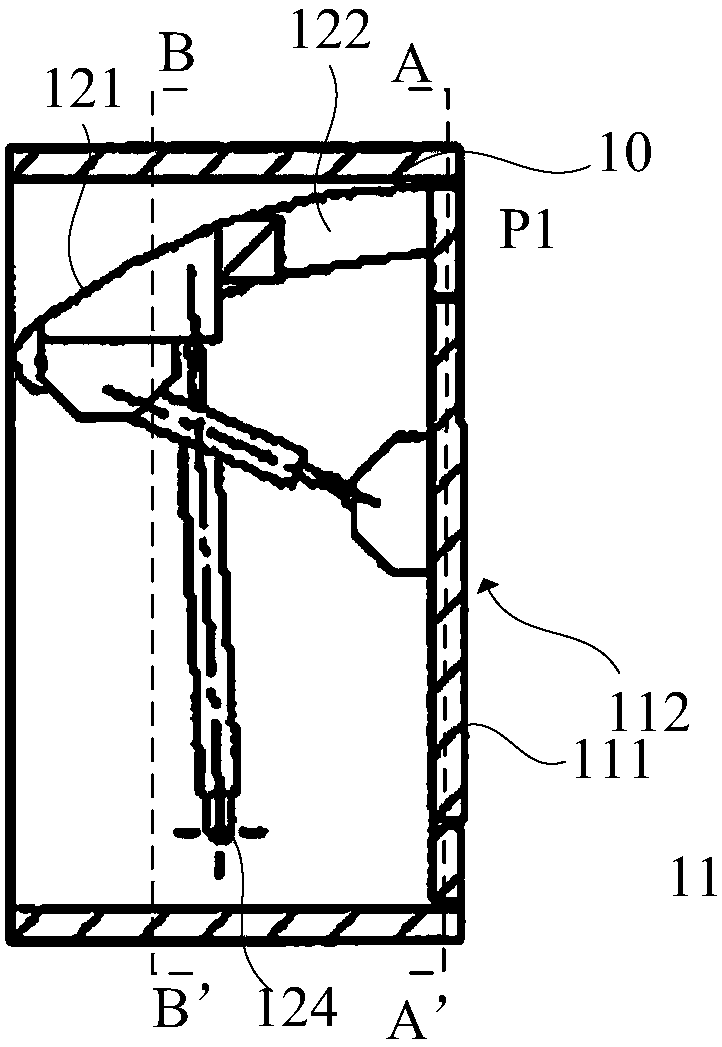

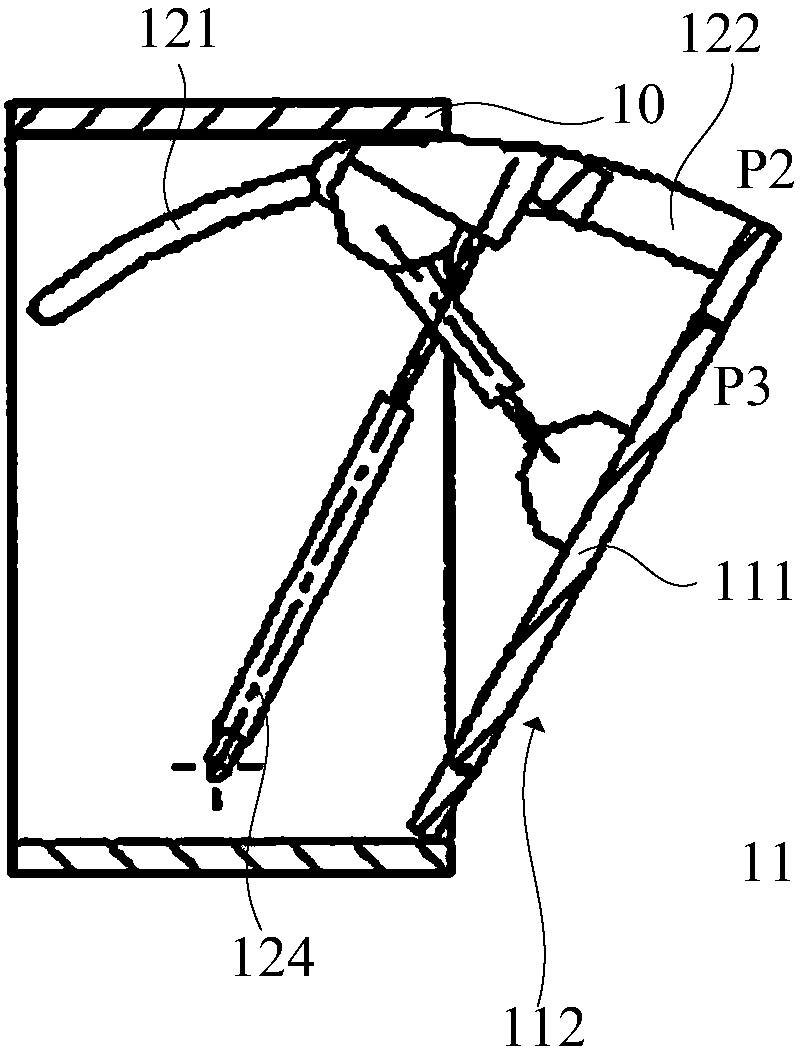

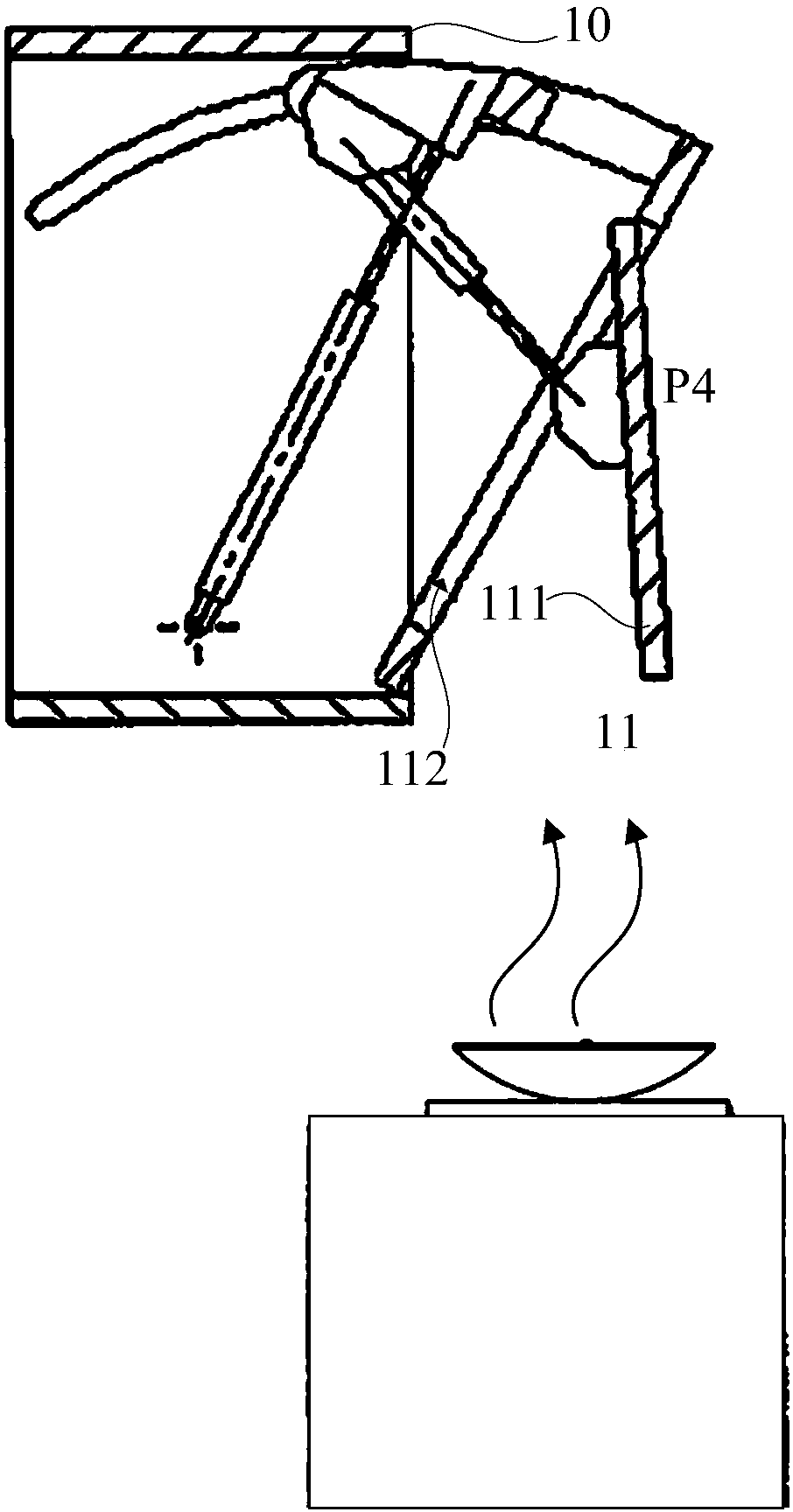

[0030] The volume of the side suction range hood in the prior art is relatively large. One of the reasons is that, in order to achieve the effect of collecting smoke, the panel at the side suction air inlet is inclined to the direction in which the oil fume rises, which takes up a large space. However, if the panel of the air inlet is set parallel to the rising direction of oil fume, it will be difficult to play the role of collecting smoke, thus affecting the smoking effect.

[0031] The invention provides a casing assembly of a range hood. In the working state, the position of the smoke inlet part is switched, and at least partially protrudes from the casing; and the deflector can also be switched from the position of closing the air inlet. to the position where the air inlet is open. Therefore, the deflector extends forward for a certain distance relative to the casing, and the position of the deflector can be adjusted to the top of the cooker, thereby improving the effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com