Full-frequency-domain identification method for vibration noise source of transformer

A vibration noise and identification method technology, applied in the direction of instruments, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problems of complex structure, poor high-frequency identification effect, wide noise frequency distribution, etc., to overcome the large volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

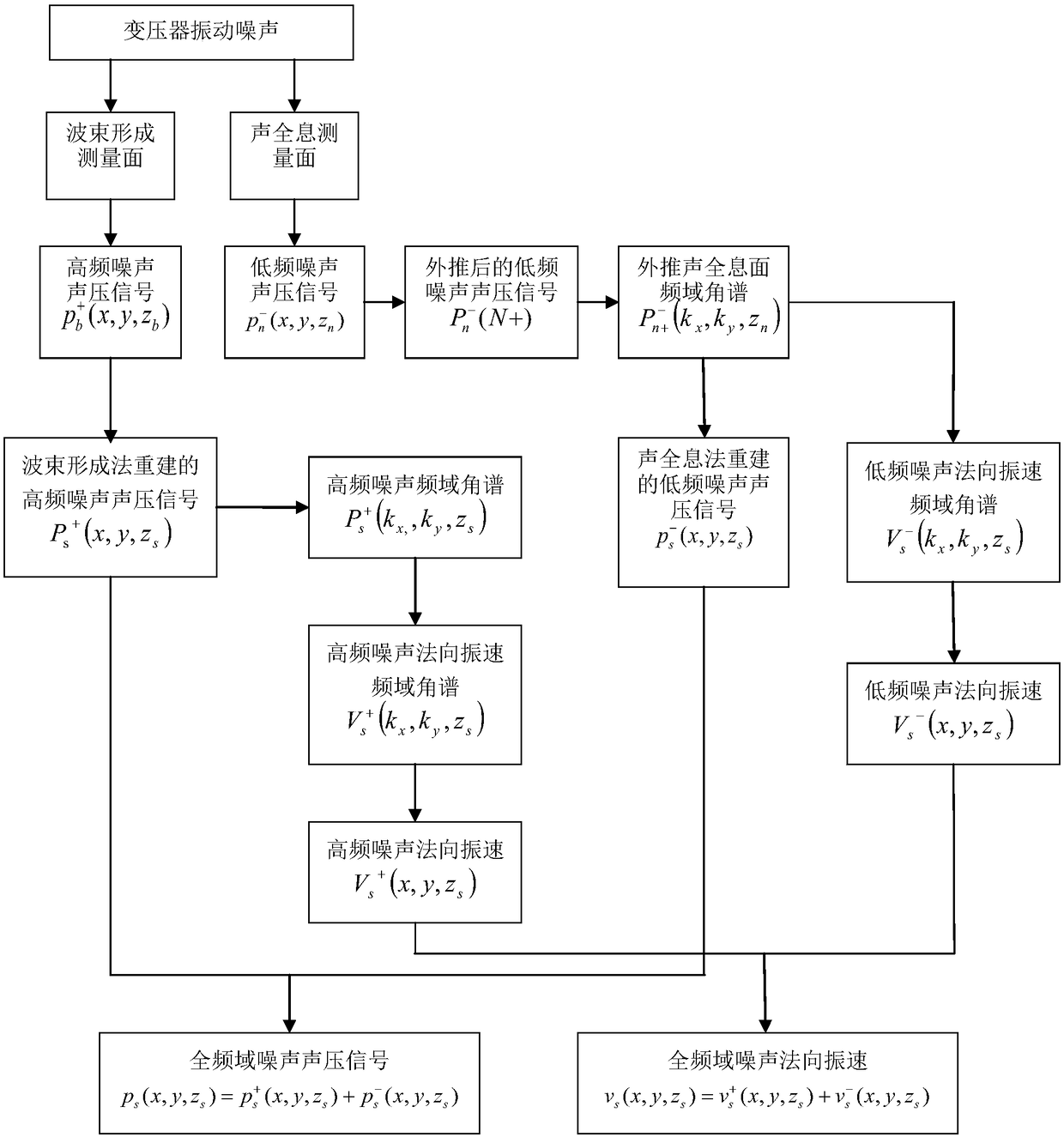

Method used

Image

Examples

Embodiment 1

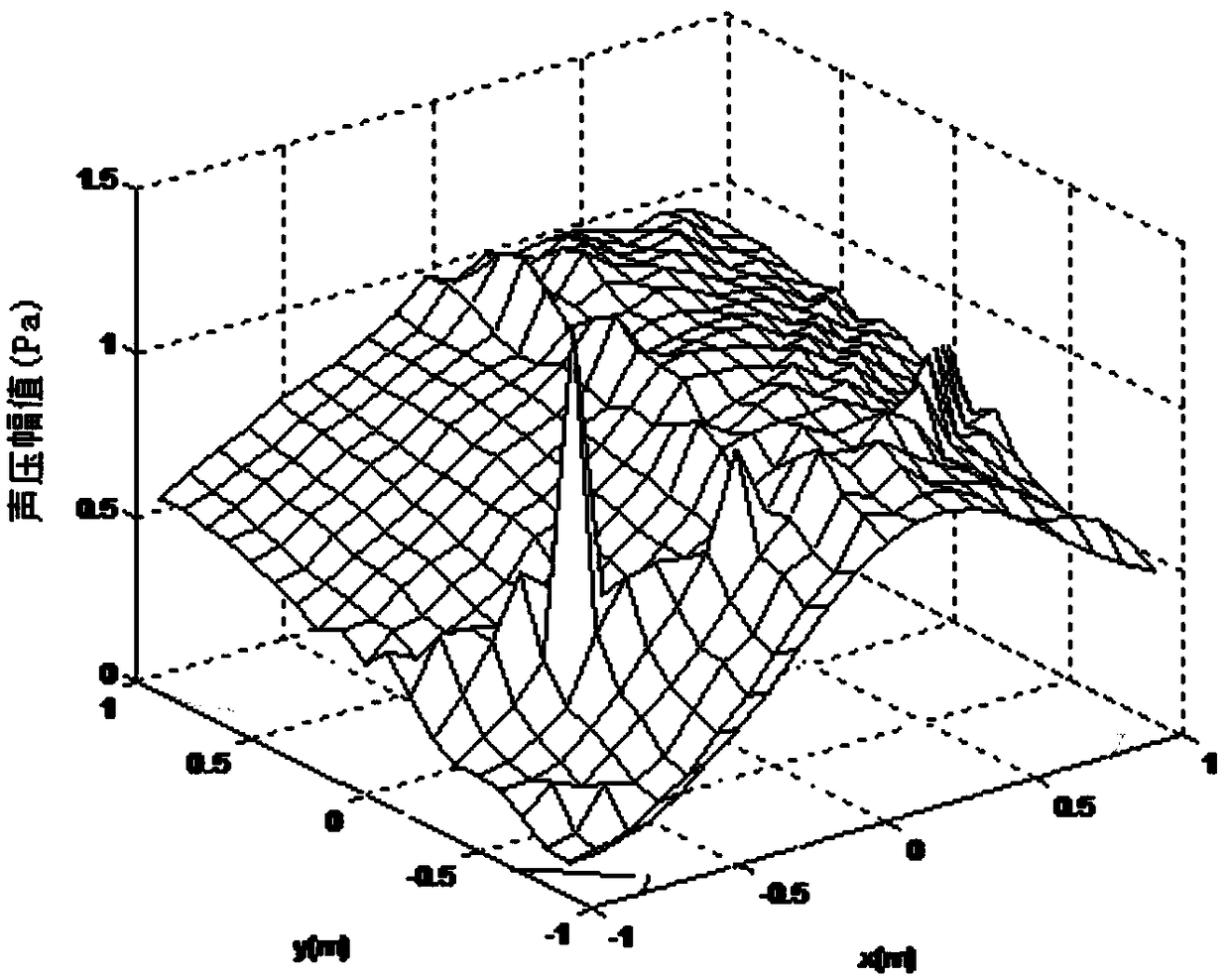

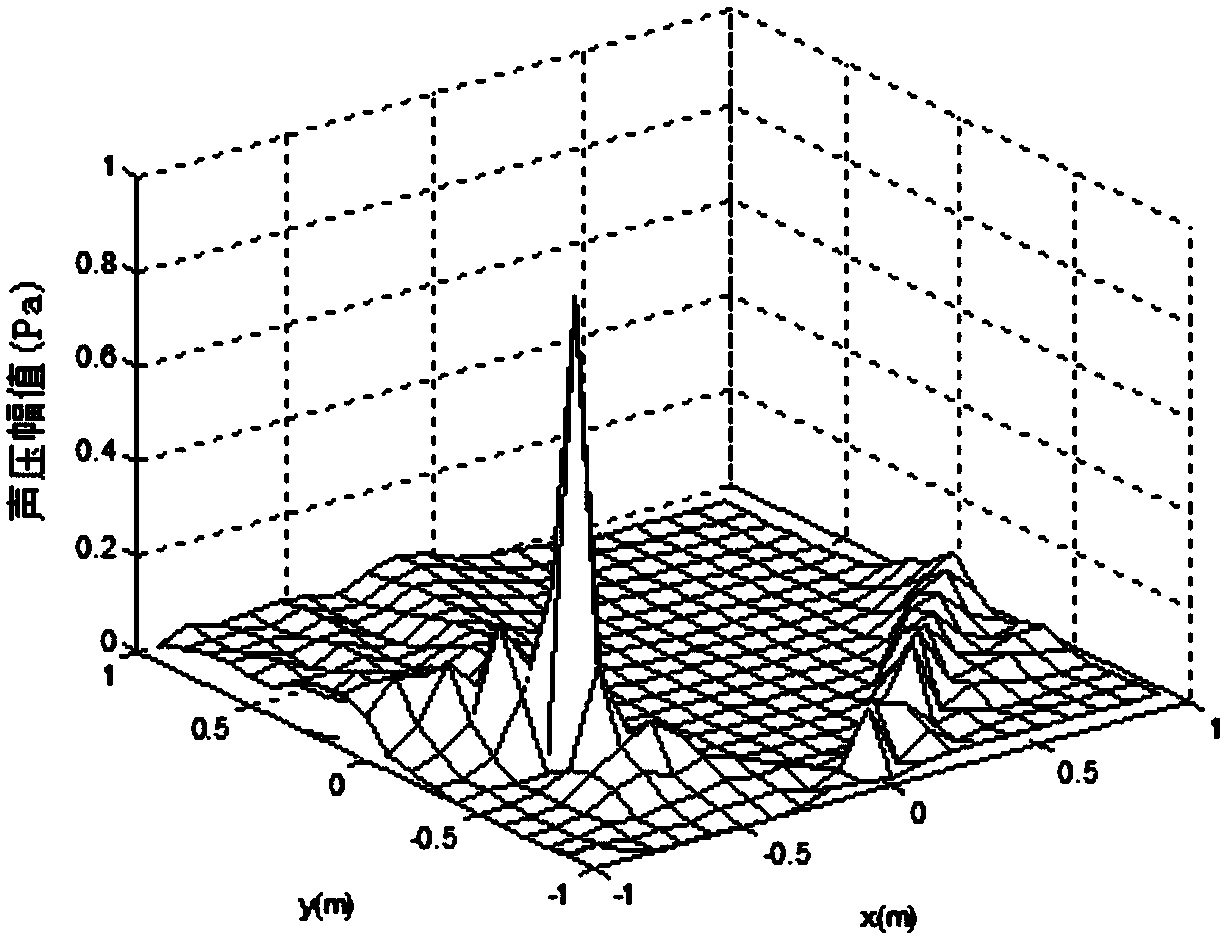

[0080] The speed of sound propagation is 340m / s, the density of air is 1.29g / L, the distance between the acoustic holographic measurement surface and the sound source surface of the transformer is 0.1m, and the front surface area of the transformer is 2×2m 2 , the aperture of acoustic holographic measurement surface N is 2×2m 2 , the number of measurement points is 10×10, and the distance between the microphones is 0.2m. After zero-padding extrapolation in the wavenumber domain, the aperture of the zero-padding extrapolation measurement surface N+ is 4×4m 2 , the number of measurement points is 20×20. The wave number shaping measurement surface is 2.17 meters away from the sound source surface of the transformer (the maximum measurement angle of the microphone is less than 30 degrees), and the aperture of the beam forming measurement surface is 0.5×0.5m 2, the number of measurement points is 5×5, the distance between microphones is 0.05m, and the signal-to-noise ratio is S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com