Numerical value control device and control method for machine tool

A numerical control device and machine tool technology, which is applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of not considering the flat surface error and the decrease of the judgment accuracy of the tool handle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 3

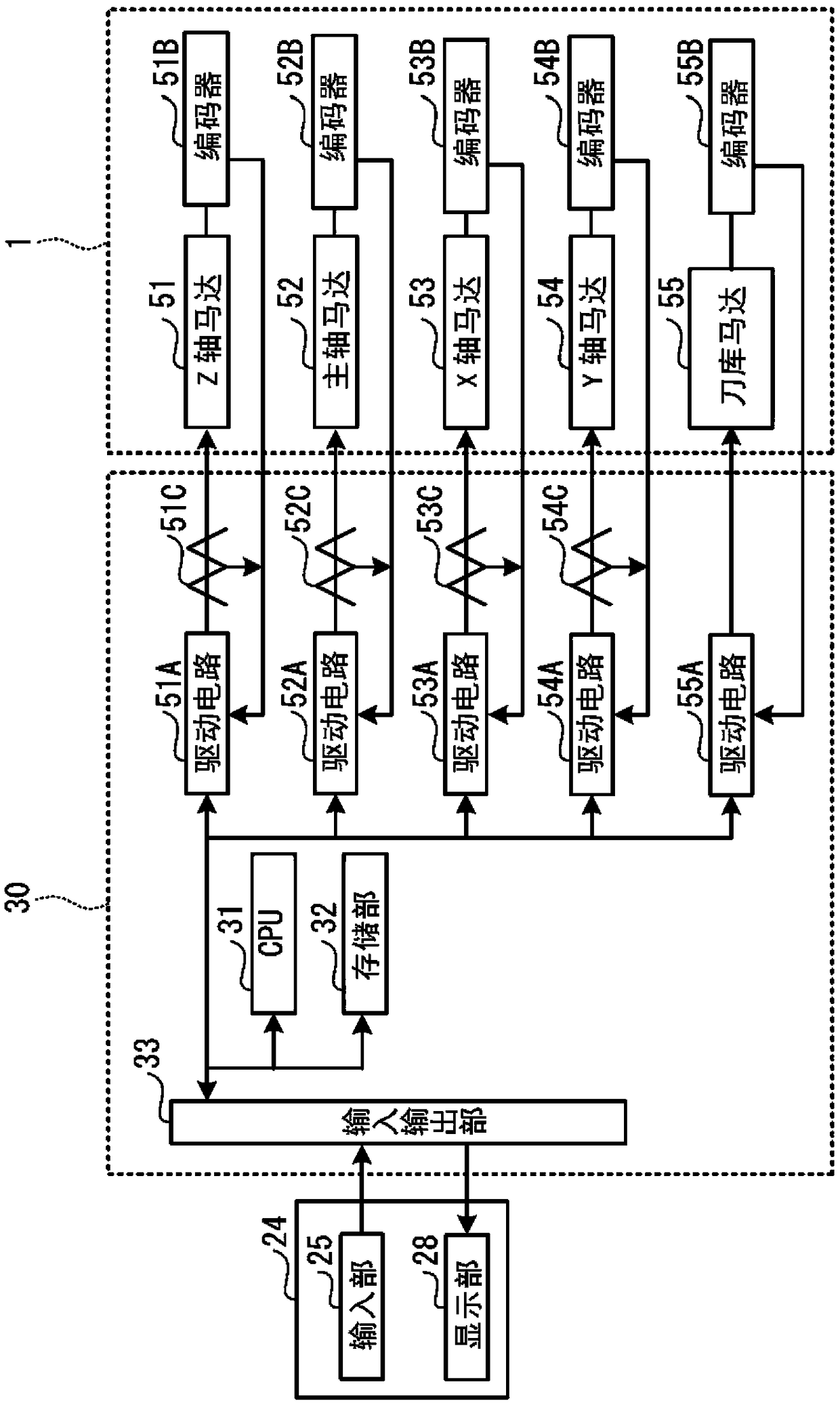

[0090] Numerical controller 30 according to Embodiment 3 can set a more appropriate drive current value by removing high-frequency components from the drive current value using LPF 56 . Therefore, the numerical control device can judge the attachment state of the toolholder with higher accuracy.

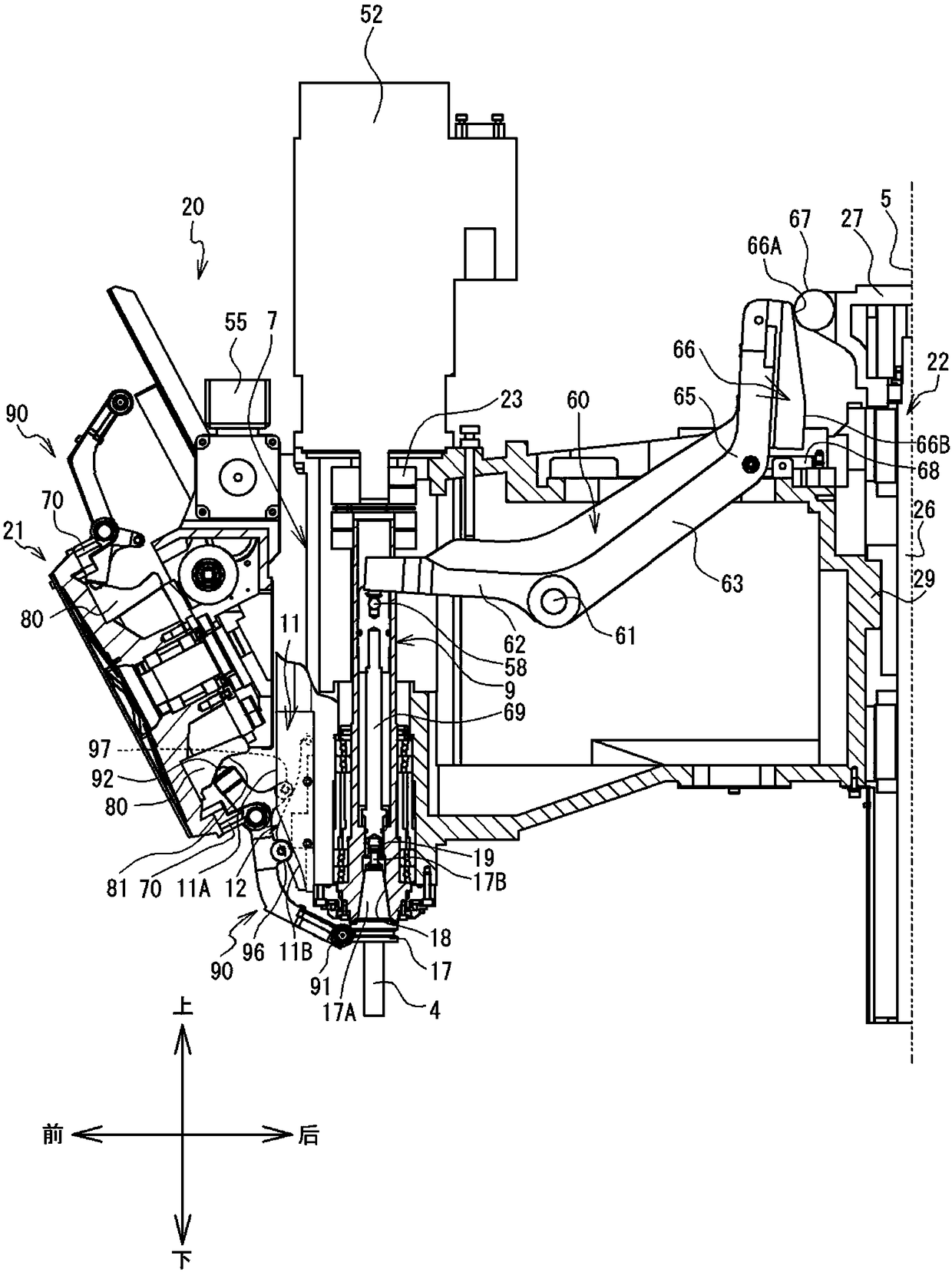

[0091] The present invention is not limited to the above-described embodiments, and various modifications are possible. The cam 66 in the above-described embodiment is fixed to the rod member 60 and supports the roller 67 on the column 5 side. For example, the roller 67 may be supported by the lever member 60 and the cam 66 may be fixed to the column 5 side. In this case, the inclined portion 66A of the cam 66 is inclined from the end portion of the straight portion 66B to the side opposite to the spindle head 7 (the column 5 side).

[0092] The drive circuit 51A to the drive circuit 55A in the above-described embodiment are provided in the numerical controller 30 , but may also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com