A method and an apparatus for determining wear depth

A technology of wear depth and time, applied in the direction of instruments, geometric CAD, calculation, etc., can solve problems such as insufficient calculation accuracy, and achieve the effect of solving insufficient calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

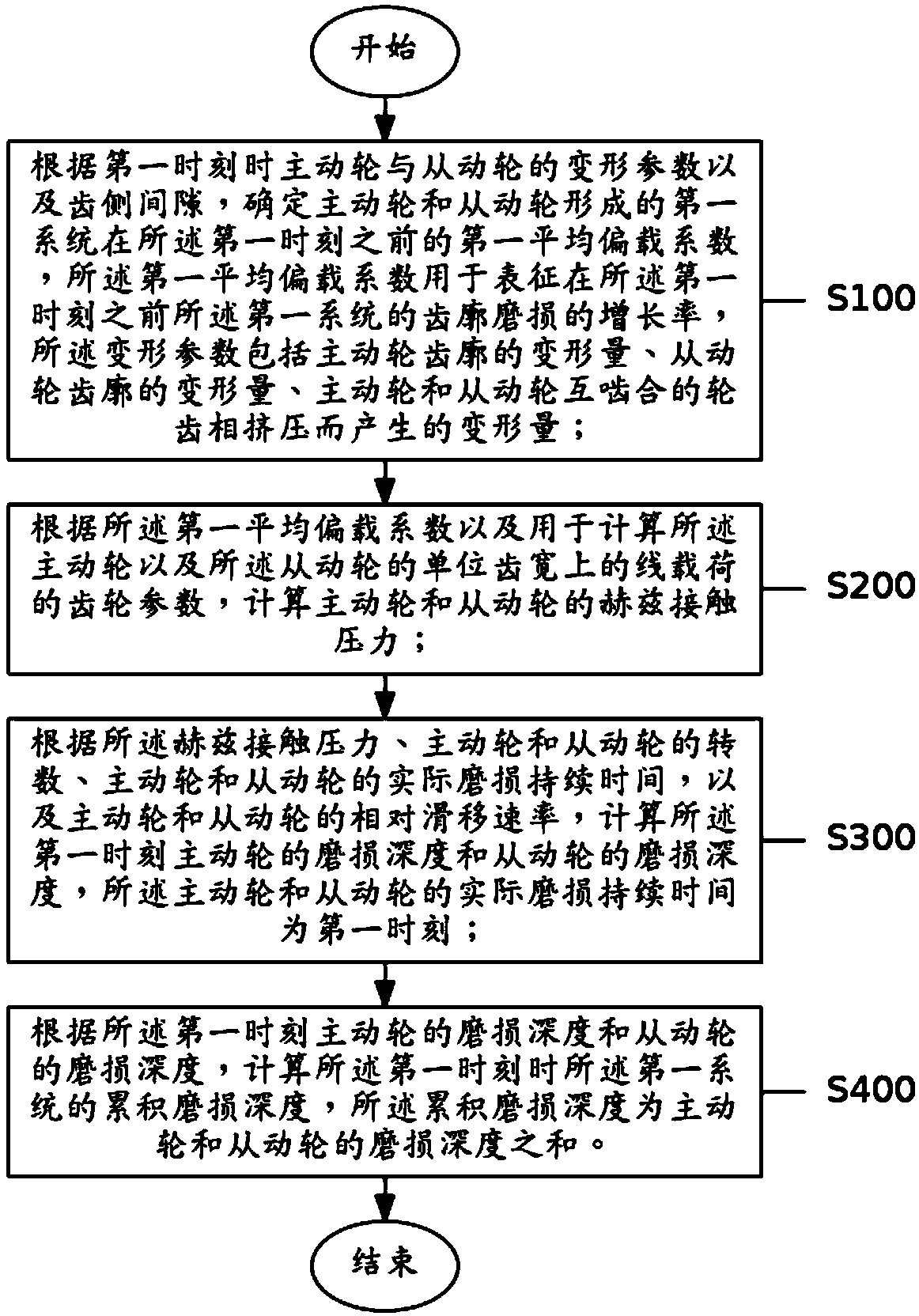

[0026] See figure 1 , figure 1 is a schematic flow chart of the method for determining the wear depth provided by the embodiment of the present application. A method for determining the depth of wear provided by the present application includes:

[0027] Step S100: According to the deformation parameters of the driving wheel and the driven wheel and the tooth backlash at the first moment, determine the first average eccentric load coefficient of the first system formed by the driving wheel and the driven wheel before the first moment, the first An average eccentric load coefficient is used to characterize the growth rate of the tooth profile wear of the first system before the first moment, and the deformation parameters include the deformation amount of the tooth profile of the driving wheel, the deformation amount of the tooth profile of the driven wheel, and the tooth profile of the driving wheel. The amount of deformation caused by the extrusion of the meshing teeth of t...

no. 2 example

[0155] See Figure 10 , Figure 10It is a schematic structural diagram of the device for determining the depth of wear provided by the embodiment of the application; a device for determining the depth of wear 100 provided by the application includes:

[0156] The average eccentric load coefficient determination module 110 is used to determine the first average value of the first system formed by the driving wheel and the driven wheel before the first moment according to the deformation parameters of the driving wheel and the driven wheel and the tooth backlash at the first moment. The eccentric load coefficient, the first average eccentric load coefficient is used to characterize the growth rate of the tooth profile wear of the first system before the first moment, and the deformation parameters include the deformation amount of the driving wheel tooth profile, the driven wheel The amount of deformation of the tooth profile, the amount of deformation caused by the extrusion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com