Wall construction method

A construction method and wall technology, applied in the direction of chemical instruments and methods, dissolution, mixers, etc., can solve the problems that coarse and fine materials cannot be mixed uniformly and affect the quality of the wall, so as to facilitate uniform mixing and improve quality , mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a wall construction method, including batching, mixing materials, building walls, forming wall embryos, plastering, blanking walls and painting walls.

Embodiment 2

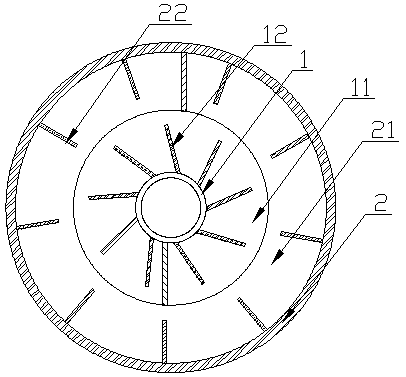

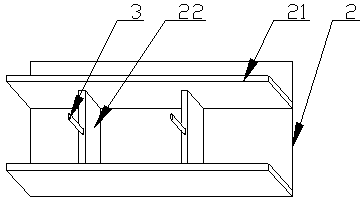

[0026] On the basis of Example 1, this embodiment further defines: the mixing step is carried out in a mixing device, and the mixing device is such as Figure 1-2 As shown, it includes an inner cylinder 1, an outer cylinder 2 and a mixing space between the inner cylinder 1 and the outer cylinder 2, the inner cylinder 1 and the outer cylinder 2 are arranged coaxially, wherein,

[0027] The outer surface of the inner cylinder 1 is provided with a first spiral deflector 11, the inner surface of the outer cylinder 2 is provided with a second spiral deflector 21, the first spiral deflector 11 and the second spiral deflector 21 the same direction of the spiral;

[0028] In the first spiral deflector 11, a coarse material mixing plate 12 is arranged between adjacent deflectors along the axial direction of the inner cylinder 1; in the second spiral deflector 21, between adjacent deflectors A fine material mixing plate 22 is arranged along the axial direction of the outer cylinder 2 ....

Embodiment 3

[0032] On the basis of Example 2, this embodiment further defines: along the radial direction of the inner cylinder 1, the length of the first spiral deflector 11 is greater than the length of the coarse material mixing plate 12; the second spiral deflector The length of the plate 21 is greater than that of the fine material mixing plate 22, so that the first spiral deflector 11 and the second spiral deflector 21 play the role of main flow diversion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com