Automatic trolley alignment machine

A trolley and automatic technology, applied in the field of automatic trolley alignment machines, can solve the problems of high labor consumption, low degree of automation and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

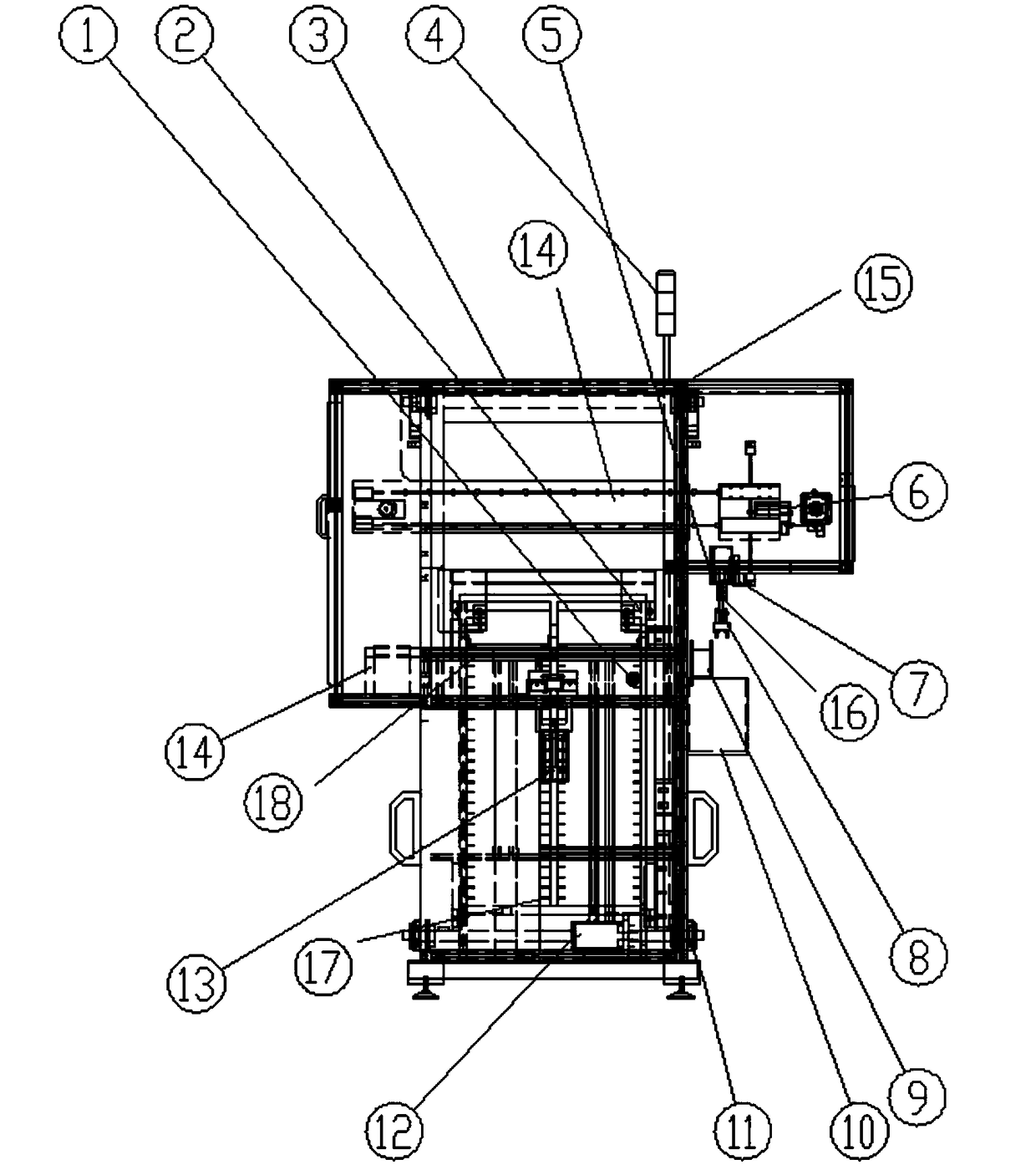

[0012] See figure 1 As shown, an automatic trolley alignment machine includes a body 1, the body 1 has a lifting device 13, an X-axis slideway assembly 14 located on the lifting device 17, a Y-axis slideway assembly 15 and a Z-axis slideway As for the component 16 , a weighing platform 2 is provided on the workbench 18 of the body 1 , and the weighing platform 2 is located on the top of the lifting device 17 .

[0013] It also includes a defective product slideway 9 connected to the end of the workbench 17 , and the bottom of the defective product slideway 9 passes through the defective product storage box 10 .

[0014] The lifting device 17 includes a trolley lifting slider 13, a trolley lifting servo motor 12 and a trolley lifting transmission bearing 11, and the trolley lifting transmission bearing 11 is in transmission connection with the trolley lifting servo motor 12, and the trolley lifting The servo motor 12 is connected with the trolley through slide rails, and a tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com