A non-submersible underwater pipeline remote operation welding maintenance equipment and method

A technology for underwater pipelines and maintenance equipment, applied to welding equipment, arc welding equipment, welding accessories, etc., can solve problems such as underwater alignment difficulties and inflexible manipulation, and achieve the effect of overcoming alignment difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0048] The non-submersible underwater pipeline remote operation welding maintenance equipment and method of the present invention, its preferred specific implementation mode is:

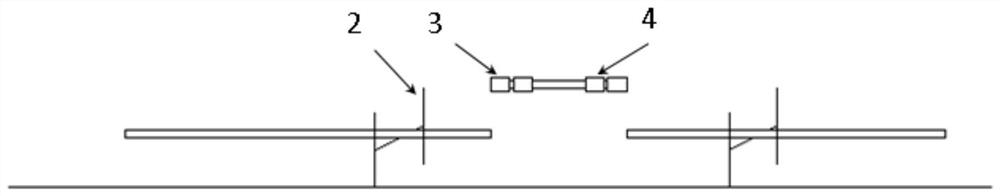

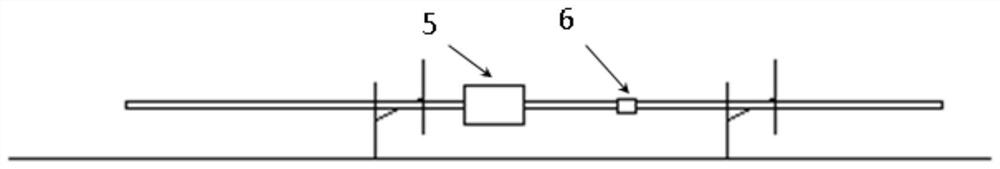

[0049] Non-submersible underwater pipeline remote operation welding maintenance equipment includes H-shaped pipeline support frame 2, casing positioner 4, welding cabin 5, and casing 9;

[0050] The H-shaped pipe support frame 2 is equipped with a hydraulically driven height adjustment mechanism 30, a left and right adjustment mechanism 31, a front and rear adjustment mechanism 32 and a pipe holding claw 33;

[0051] The casing positioner 4 is provided with a hydraulically driven casing positioning claw 34;

[0052] The sleeve 9 has a wedge-shaped sealing ring 10;

[0053] Prefabricate a new pipe section 11 on board the ship according to the length of the damaged old pipe section. Before the prefabricated new pipe section 11 is placed underwater, the casing positioner 4 and the casing pipe 9 with a ...

specific Embodiment

[0081] Such as Figures 1 to 13 As shown, the non-submersible underwater pipeline remote operation welding repair equipment and method provided by the embodiment of the present invention can realize the remote welding repair operation of deep water damaged pipelines, and the maintenance process does not require divers to assist operations. The main equipment includes:

[0082] H-shaped pipe support frame 2, casing positioner 4, welding cabin 5, casing 9, wedge-shaped sealing ring 10, left and right welding chambers 12 and 17, welding cabin driving gear 13, welding cabin driving room 14, welding cabin opening Combined hydraulic cylinder 15, welding cabin flap 16, welding cabin drainage chamber 18, welding cabin weight adjustment room 19, welding cabin claw 20, clamp 21, welding cabin driving driven gear 22, welding cabin camera lighting mechanism 23, welding torch angle Adjustment mechanism 24, welding torch clamping mechanism 25, welding room automatic hatch 26, welding room s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com