A kind of surface acoustic wave device and its preparation method

A surface acoustic wave device, a technology of acoustic wave velocity, applied in electrical components, impedance networks, etc., can solve the problems of limited improvement of the quality factor of surface acoustic wave devices, inability to effectively reduce the number of spurious modes, etc. The effect of the quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

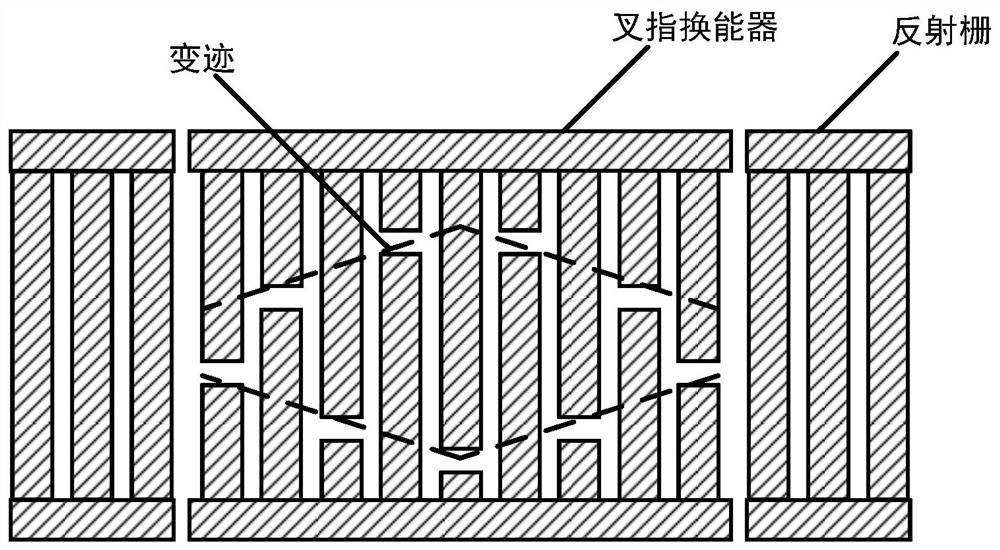

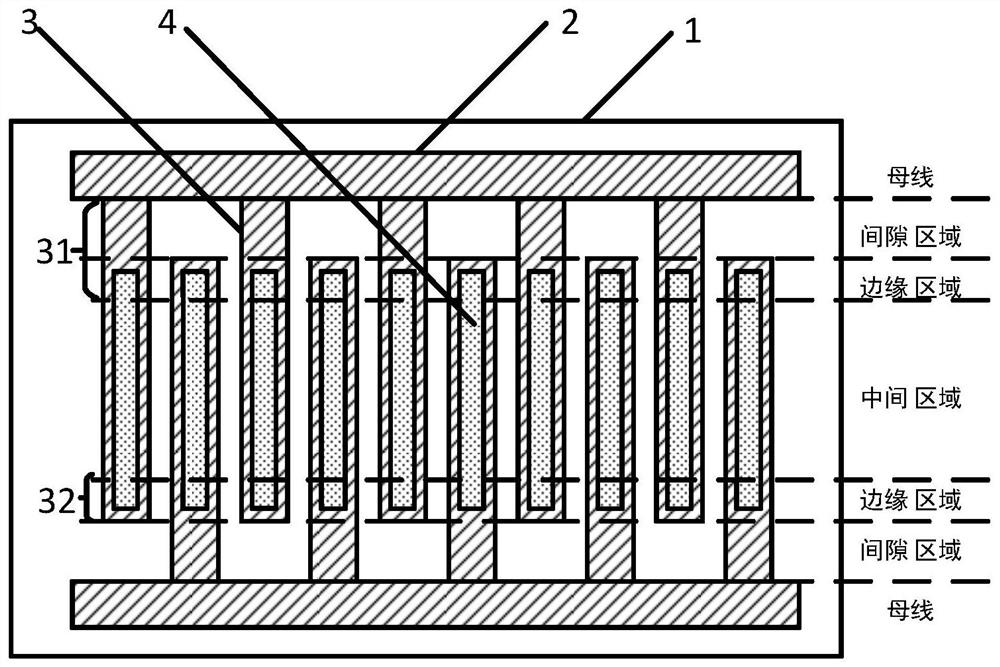

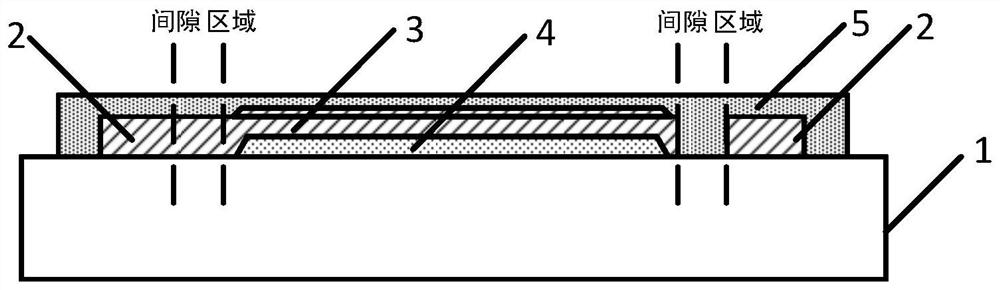

[0051] The core of the invention is to provide a surface acoustic wave device. In the prior art, the apodization method is usually selected to improve the quality factor of the surface acoustic wave device. The so-called apodization method means that the position of the opening between the two opposite electrodes in the interdigital transducer changes regularly between the two bus bars, such as figure 1 as shown, figure 1It is a top view of a surface acoustic wave device in the prior art. exist figure 1 In the figure, from left to right, the openings between the two opposing electrodes in the interdigital transducer are distributed from the middle to the bus bar, and then distributed from the position close to the bus bar to the middle. However, the position of the opening between the two opposing electrodes in the IDT has a significant impact on the waveform, and changing the position of the opening between the two electrodes along the direction of the generatrix correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com