Rotatable sliding front supporting device for bending machine

A bending machine and rotary technology, applied in the field of bending machines, can solve the problems of inability to meet the requirements of machining accuracy, poor positioning accuracy, complicated operation, etc., and achieve the effects of good promotion and use value, convenient use and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

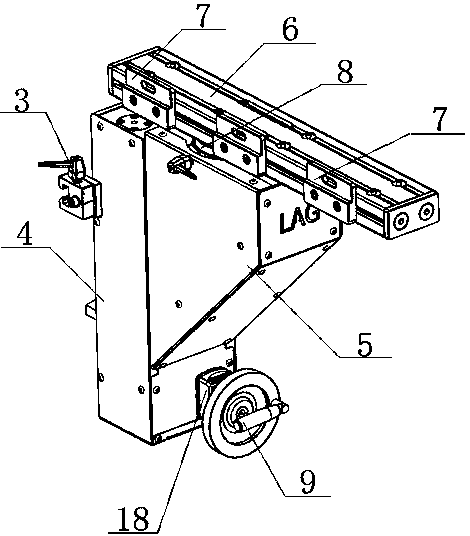

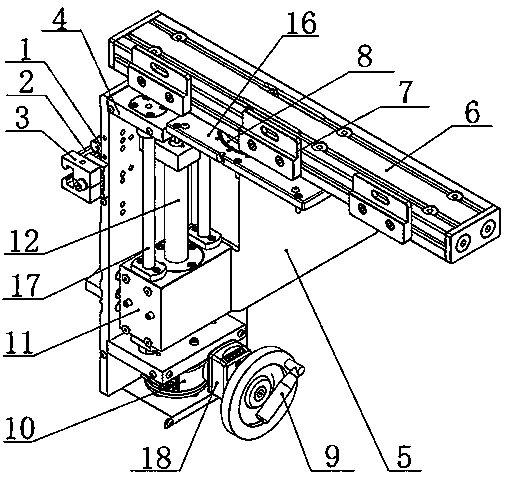

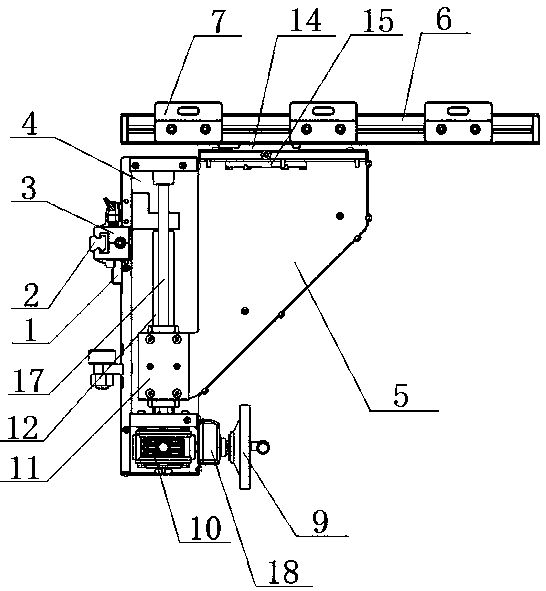

[0032] The rotatable sliding front supporting device for bending machine of the present invention includes a frame, a front and rear sliding device, a lifting drive device and a material supporting device, and the front and rear sliding device includes a slider seat 1, a fixed slide rail 2 and a locking clamp 3. The fixed slide rail 2 is fixed on the bending machine through bolts, the slider seat 1 is set on the fixed slide rail 2 and can slide on the fixed slide rail 2; the slider seat 1 is fixed on the side wall of the frame, and the lock The clamping block 3 is movably arranged on the fixed slide rail 2; the frame includes a fixed frame 4 and a mobile frame 5, the lifting drive device is arranged in the fixed frame 4, and the supporting device is arranged above the mobile frame 5;

[0033] The material supporting device comprises a material supporting slide rail 6 and a rear baffle 7, and two rear baffle plates 7 are arranged on the outside of the material supporting slide r...

Embodiment 2

[0037] The rotatable sliding front supporting device for bending machine of the present invention includes a frame, a front and rear sliding device, a lifting drive device and a material supporting device, and the front and rear sliding device includes a slider seat 1, a fixed slide rail 2 and a locking clamp 3. The fixed slide rail 2 is fixed on the bending machine through bolts, the slider seat 1 is set on the fixed slide rail 2 and can slide on the fixed slide rail 2; the slider seat 1 is fixed on the side wall of the frame, and the lock The clamping block 3 is movably arranged on the fixed slide rail 2; the frame includes a rectangular frame structure fixed frame 4 and a triangular frame structure mobile frame 5, the lifting drive device is arranged in the fixed frame 4, and the supporting device is arranged on the mobile machine above shelf 5;

[0038] The material supporting device comprises a material supporting slide rail 6 and a rear baffle 7, two sliding blocks 13 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com