Off-line full-automatic marking facility

A fully automatic and marking technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of automatic positioning of PCB, the fixing effect cannot meet the use requirements, high cost, and poor adsorption force, etc., to achieve improved Finished product marking effect, high degree of automation, and effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

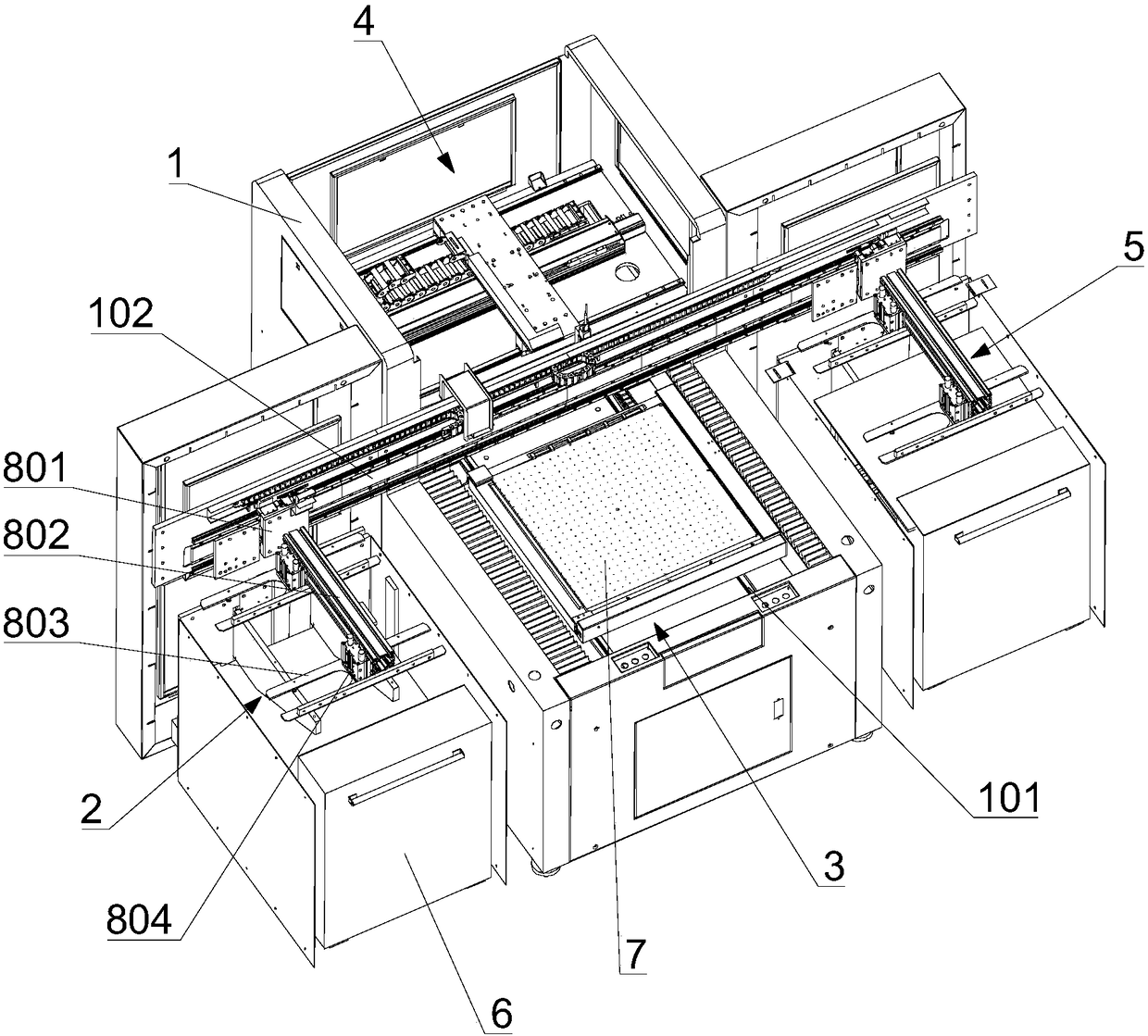

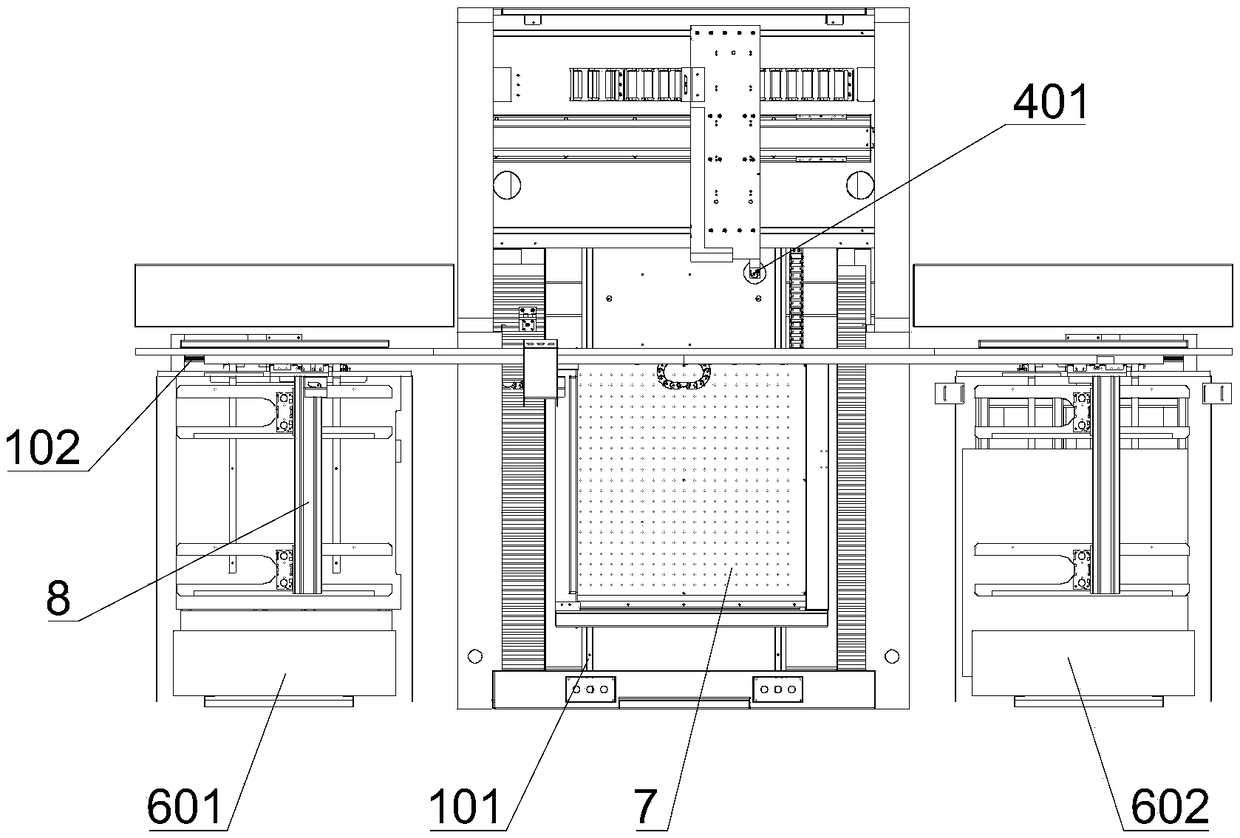

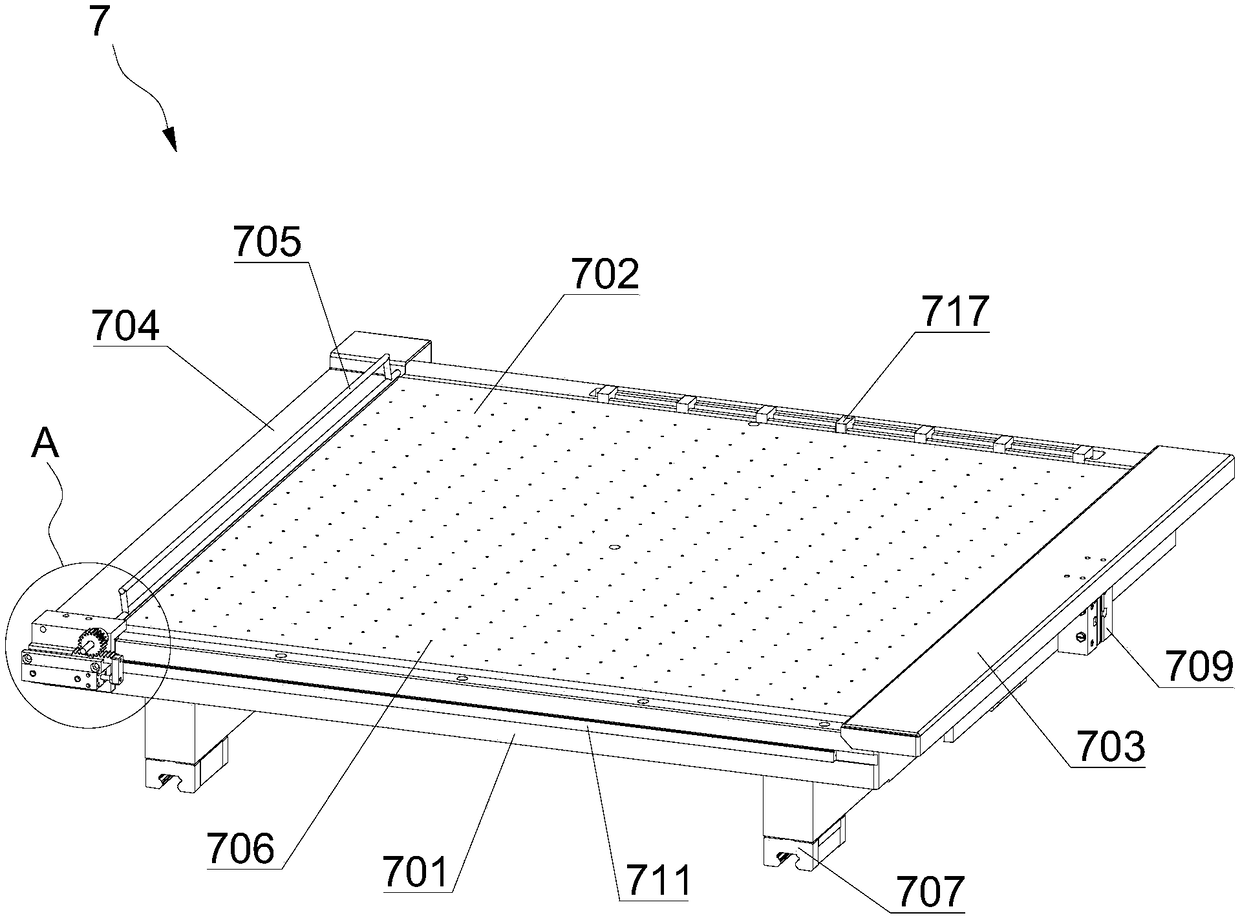

[0028] See Figure 1 to 10 As shown, this embodiment provides an offline full-automatic marking device, which mainly includes a structural frame 1 and a loading zone 2, an adsorption zone 3, a marking zone 4, and a discharge zone 5 formed.

[0029] The loading area 2 and the unloading area 5 are respectively provided with movable material carts 6, which are respectively used to hold unmarked products and marked finished products.

[0030] The loading zone 2, the marking zone 4, and the unloading zone 5 are respectively located on the relatively left, upper and right sides of the adsorption zone 3. The structural frame 1 is provided with a first guide rail 101 communicating with the adsorption zone 3 and the marking zone 4. And the second guide rail 102 that connects the loading zone 2, the adsorption zone 3 and the unloading zone 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com