An electrical safety sign

A technology for electric safety and signage, applied to illuminated signs, coatings, instruments, etc., can solve the problems of potential safety hazards, poor reflective effect, high cost, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

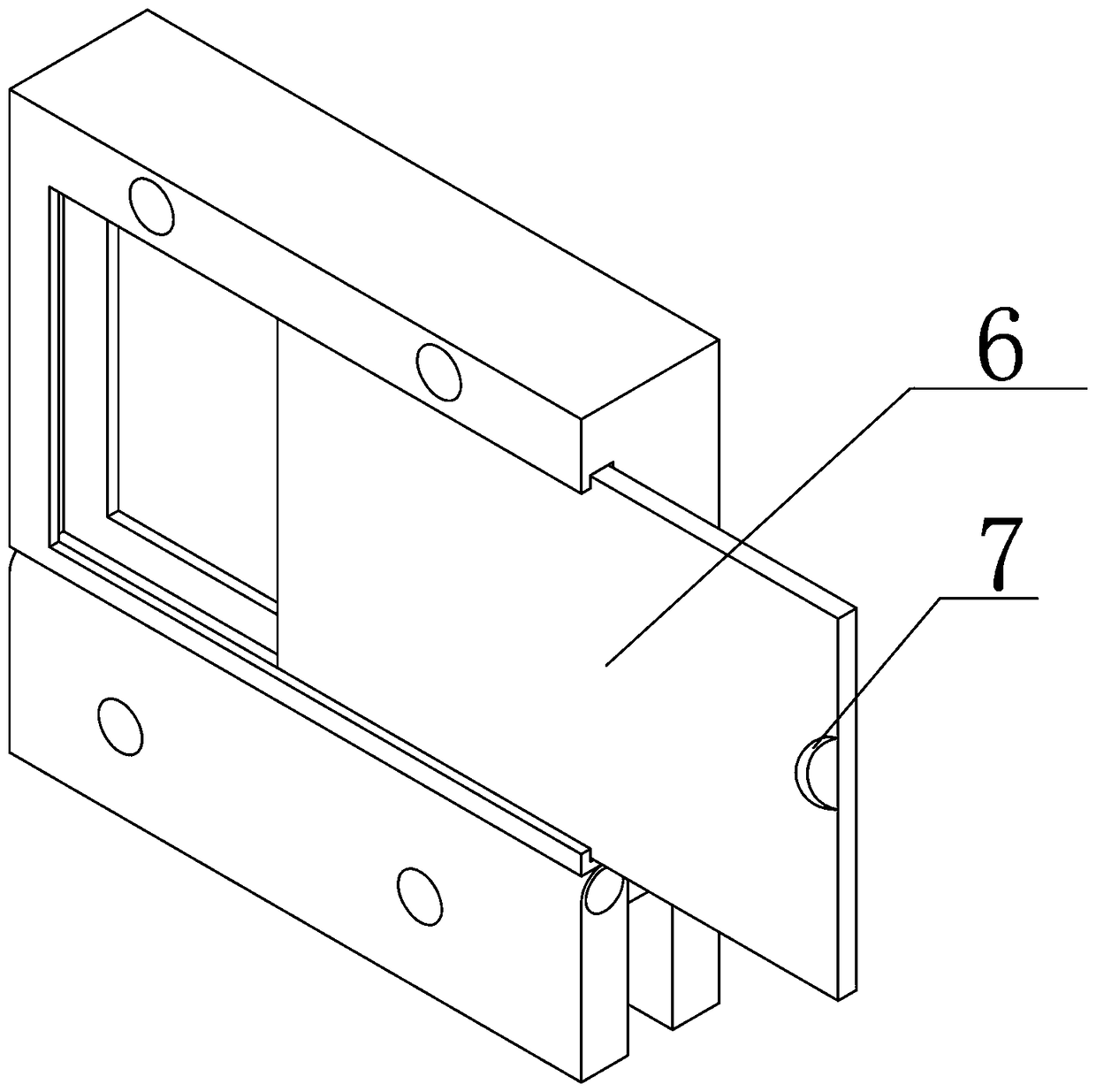

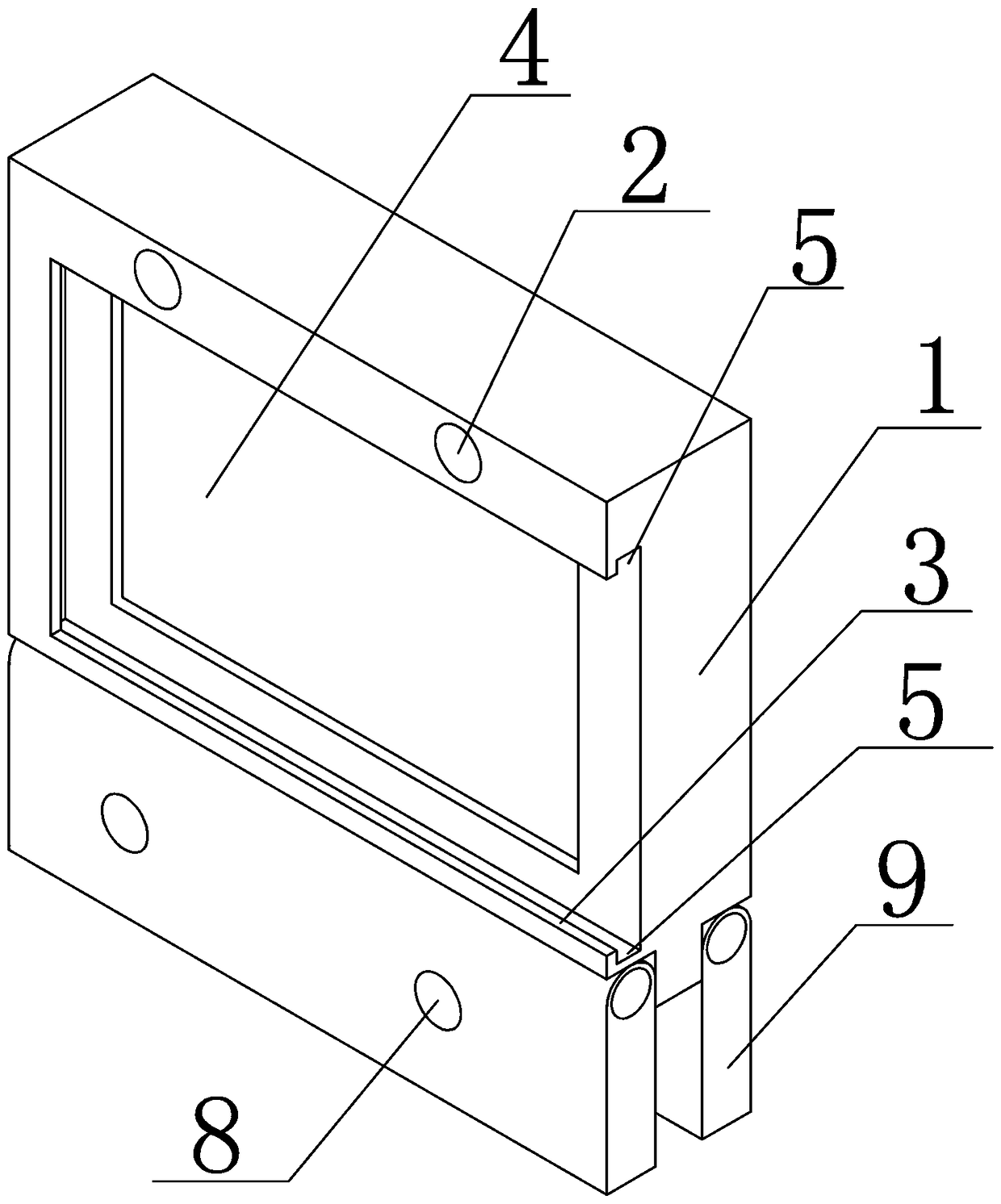

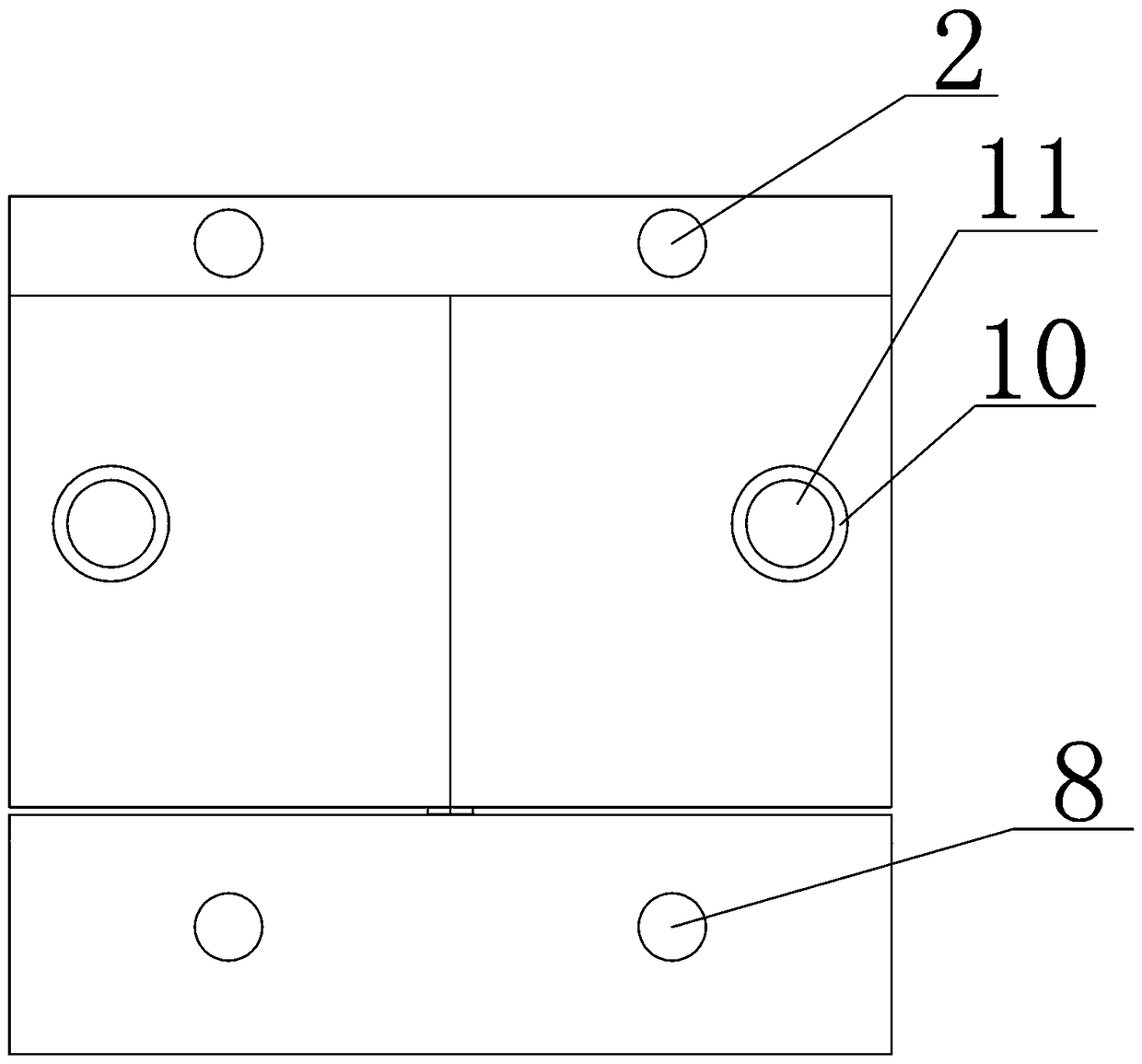

[0027] like figure 1 , figure 2 and image 3 As shown, an electrical safety identification plate includes a substrate 1, a first mounting hole 2 is provided on the upper part of the substrate 1, and a first groove 3 and a second groove 4 communicating with each other are sequentially arranged on the upper surface of the substrate 1 from outside to inside, wherein the first The opening size of the first groove 3 is larger than the opening size of the second groove 2, and the upper and lower inner walls of the first groove 3 are provided with a slideway 5, and a transparent plate 6 is arranged in the slideway 5, and the transparent plate 6 can be a transparent acrylic plate or a transparent PVC plastic Plate, in this embodiment, the transparent plate 6 is a transparent acrylic plate, and a handle 7 is arranged on the transparent plate 6; the transparent plate 6 passes through the inner wall of the first groove 3 and slides horizontally along the slideway 5, and a warning is pl...

Embodiment 2

[0034] The structure of the electrical safety identification plate of this embodiment is the same as that of Embodiment 1, except that the reflective coating is prepared from the following raw materials in parts by weight: 32 parts of acrylic resin, 20 parts of styrene-acrylic emulsion, 22 parts of reflective material, and 2.2 parts of glass fiber. 22 parts of talcum powder, 13 parts of ethanol, 6 parts of water, and 1.2 parts of dispersant sodium tripolyphosphate.

[0035]The preparation method of reflective material comprises the following steps: the TiO 2 , aluminum powder and glass microspheres are mixed in a weight ratio of 1:1:2.5, dispersed in an aqueous solution of γ-aminopropyltriethoxysilane with a mass fraction of 2%, stirred for 50 minutes, filtered to remove the filtrate, and dried. That is, the reflective material is prepared.

[0036] where TiO 2 The particle diameter of the aluminum powder is 200nm, the particle diameter of the aluminum powder is 100nm, and t...

Embodiment 3

[0039] The structure of the electrical safety identification plate of this embodiment is the same as that of Embodiment 1, except that the reflective coating is prepared from the following raw materials in parts by weight: 34 parts of acrylic resin, 12 parts of styrene-acrylic emulsion, 24 parts of reflective material, glass fiber 2.6 parts, 26 parts of talcum powder, 12 parts of ethanol, 7 parts of water, 1.6 parts of dispersant sodium hexametaphosphate.

[0040] The preparation method of reflective material comprises the following steps: the TiO 2 , aluminum powder and glass microspheres are mixed in a weight ratio of 1:1:3, dispersed in an aqueous solution of γ-aminopropyltriethoxysilane with a mass fraction of 3%, stirred for 60 minutes, filtered to remove the filtrate, and dried. That is, the reflective material is prepared.

[0041] where TiO 2 The particle diameter of the aluminum powder is 150nm, the particle diameter of the aluminum powder is 90nm, and the particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com