LNG pipeline based on offshore engineering platform

A technology of liquefied natural gas and marine engineering, applied in the field of liquefied natural gas pipelines, can solve the problems of uneven stress on pipe fittings, unfavorable assembly operations, and inconvenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

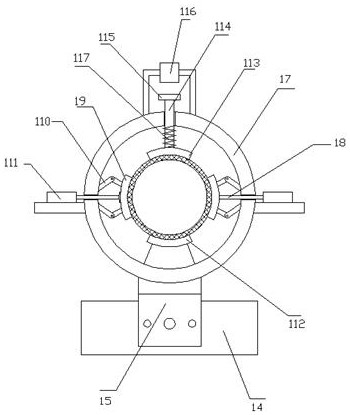

[0064] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

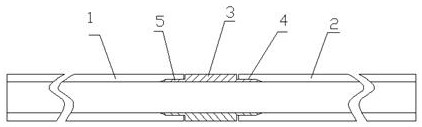

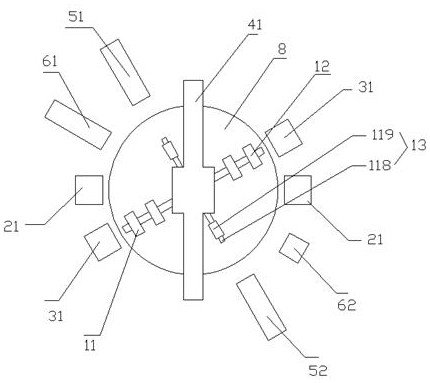

[0065] A liquefied natural gas delivery pipeline based on an offshore engineering platform, comprising a first pipeline 1, a second pipeline 2 and a connecting pipe 3, the outer wall of the connecting pipe is a regular octagonal structure;

[0066] The inner walls of the connection ends of the first pipe and the second pipe are respectively provided with a socket 4, and the socket blocks 5 at both ends of the pipe are inserted into the sockets of the first pipe or the second pipe respectively. be fixed by welding with the first pipeline and the second pipeline;

[0067] The conveying pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com