Down folding type runner removal device for automated packaging system

A packaging system and flow channel technology, applied in metal processing and other directions, can solve the problems of unusable and different flow channels, and achieve the effect of wide application range, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] For the convenience of description, "left", "right" and figure 1 with 6 The left and right directions are the same.

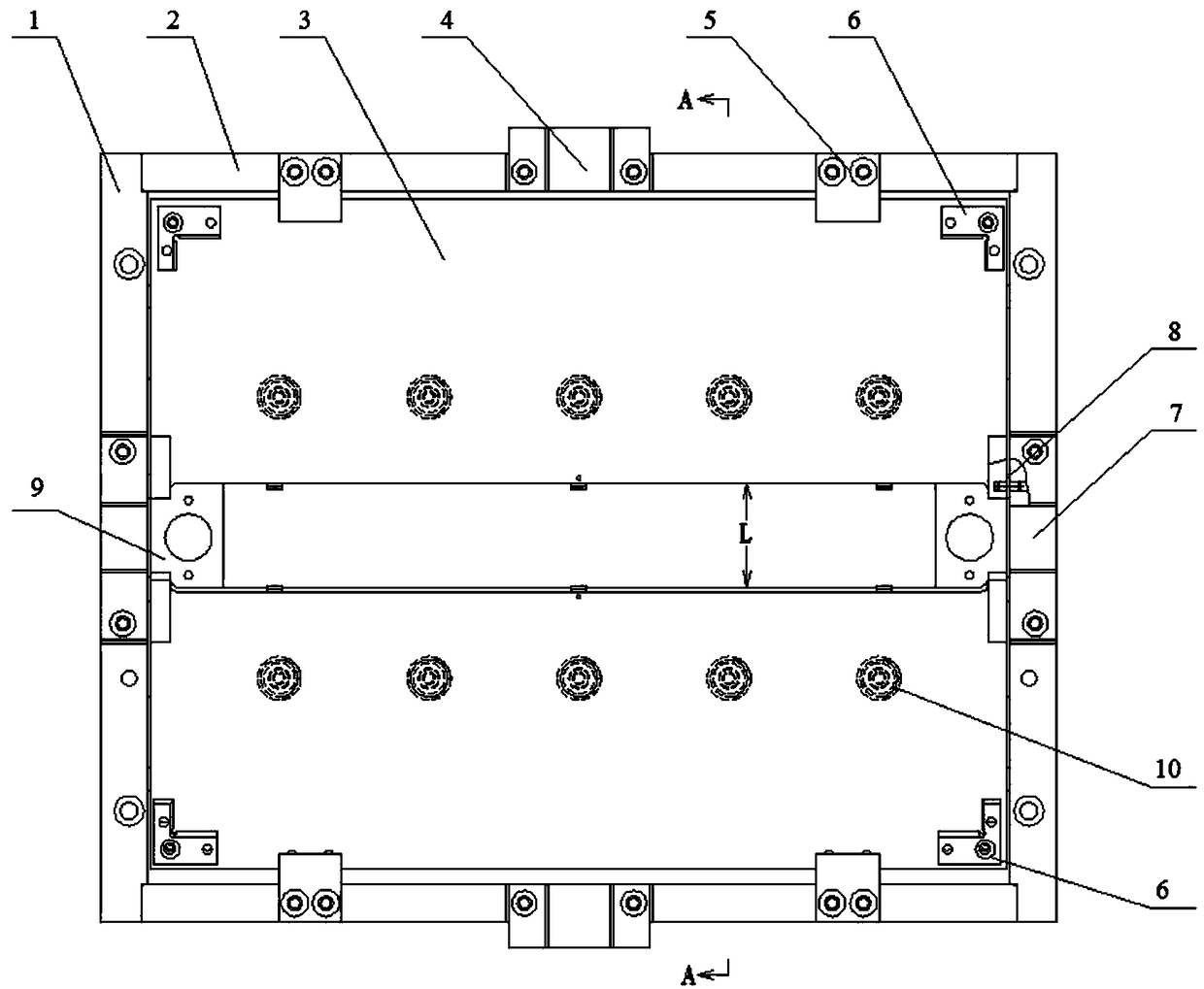

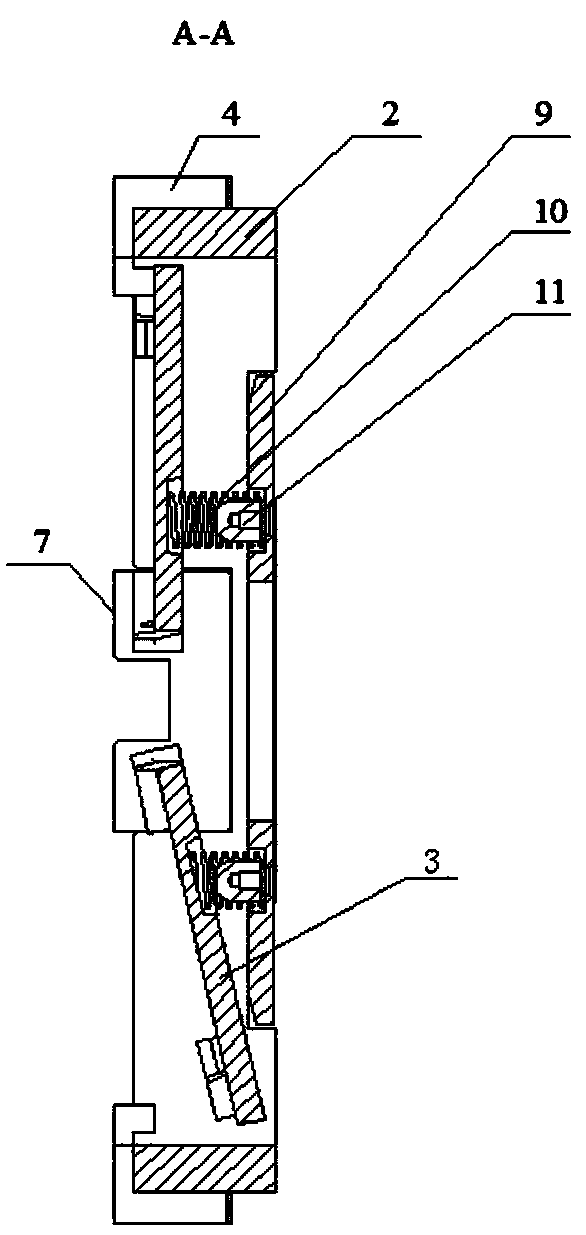

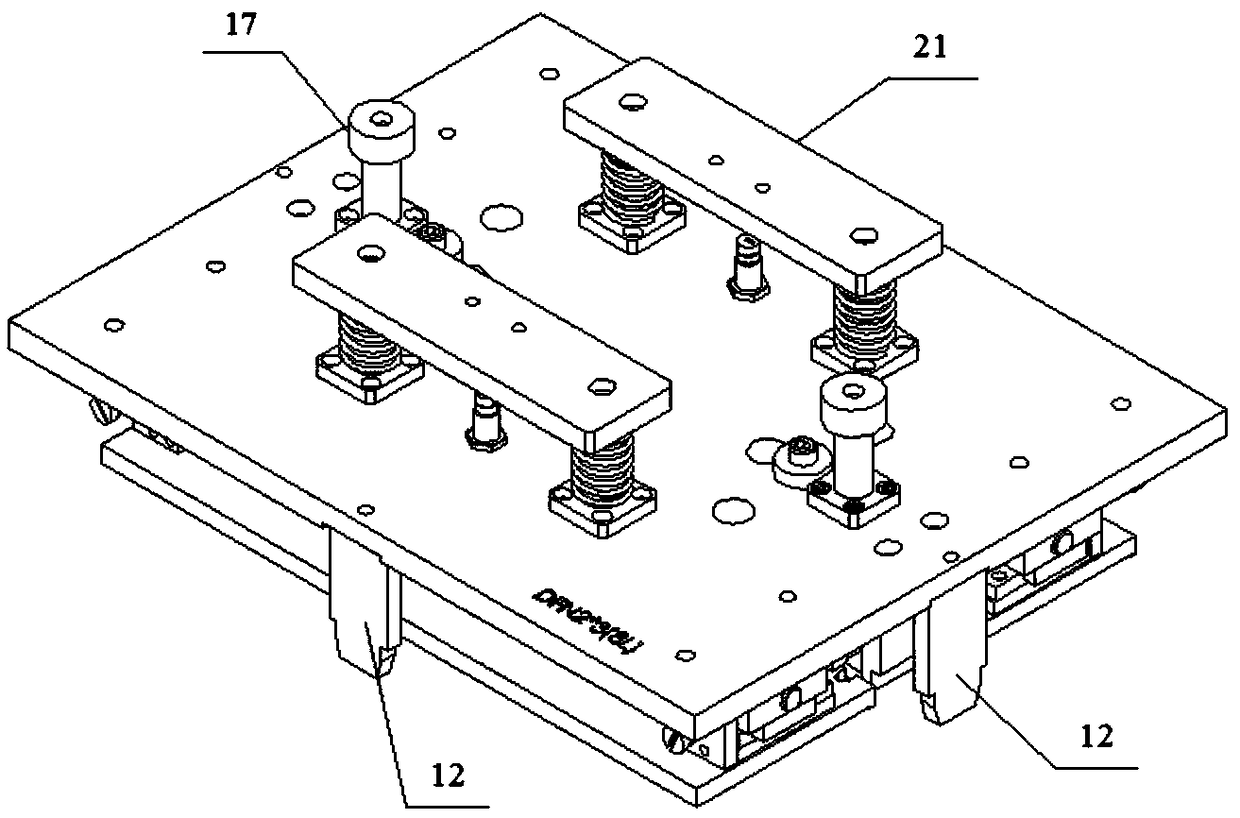

[0029] Such as Figure 1-12 As shown, a fold-down runner device for an automatic packaging system includes a die mechanism and a punch mechanism. The die mechanism includes two frames one 1, two frames two 2, two dies 3, two die locking blocks one 4, four limit blocks one 5, four positioning blocks 6, two Die locking block two 7, four revolving pins one 8, fixed plate 9, ten springs 10 and ten spring positioning pins 11; die locking block one 4 and die locking block two 7 are respectively provided with groove.

[0030] Two frames one 1 and two frames two 2 are symmetrically fixedly connected to form an outer frame, the outer frame is rectangular, the middle part of frame one 1 is provided with a die locking block two 7, and the two ends of the die locking block two 7 A revolving pin 18 is provided respectively; the middle part of the frame 2 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com