Machine for concrete cutting

A concrete and cutting mechanism technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of inconvenient, laborious, old dust and other problems in making concrete blocks, and achieve the effect of saving manual movement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

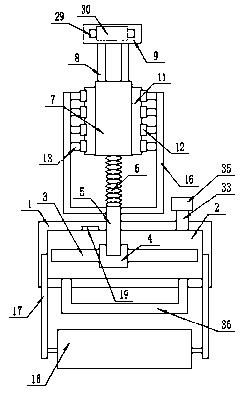

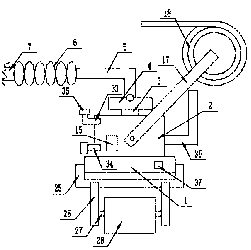

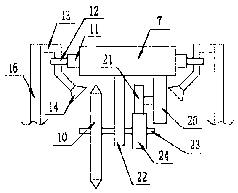

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a machine for concrete cutting includes a strip bearing base 1, a concrete cutting mechanism is set on the upper surface of the strip bearing base 1, a moving mechanism is set on the lower surface of the strip bearing base 1, and the The concrete cutting mechanism is mainly composed of a strip-shaped water storage box 2 arranged on the upper surface of the strip-shaped bearing base 1, a strip-shaped slide rail 3 arranged on the upper surface of the strip-shaped water storage box 2, and a strip-shaped slide rail 3 arranged on the strip-shaped water storage box 2. The movable block 4 on the upper surface, the swing support arm 5 hinged on the upper surface of the movable block 4, the horizontal tension spring 6 arranged on the end surface of the swing support arm 5, the strip support block 7 arranged on the end surface of the horizontal tension spring 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com