Material flow-dividing device for plastic mould

A technology of a shunt device and a plastic mold, applied in the field of plastic molds, can solve the problems of a single structure of the shunt device, increase the strength of the work, reduce the efficiency of the work, etc., and achieve the effect of facilitating the work, reducing the strength and shortening the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

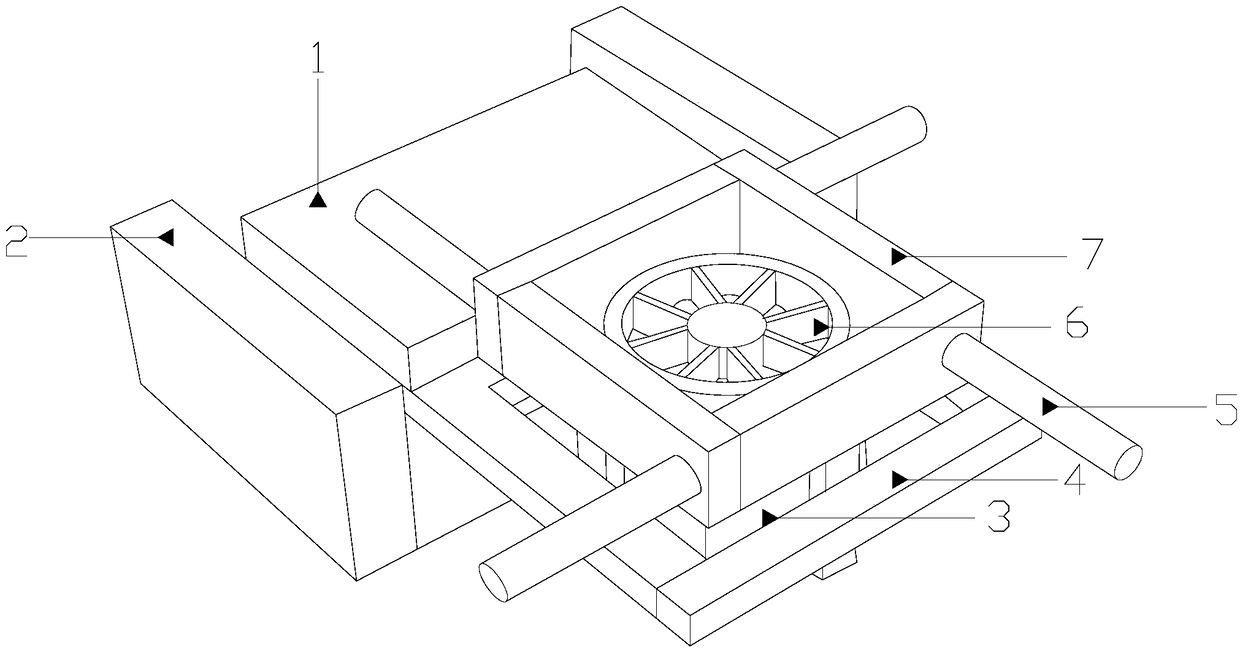

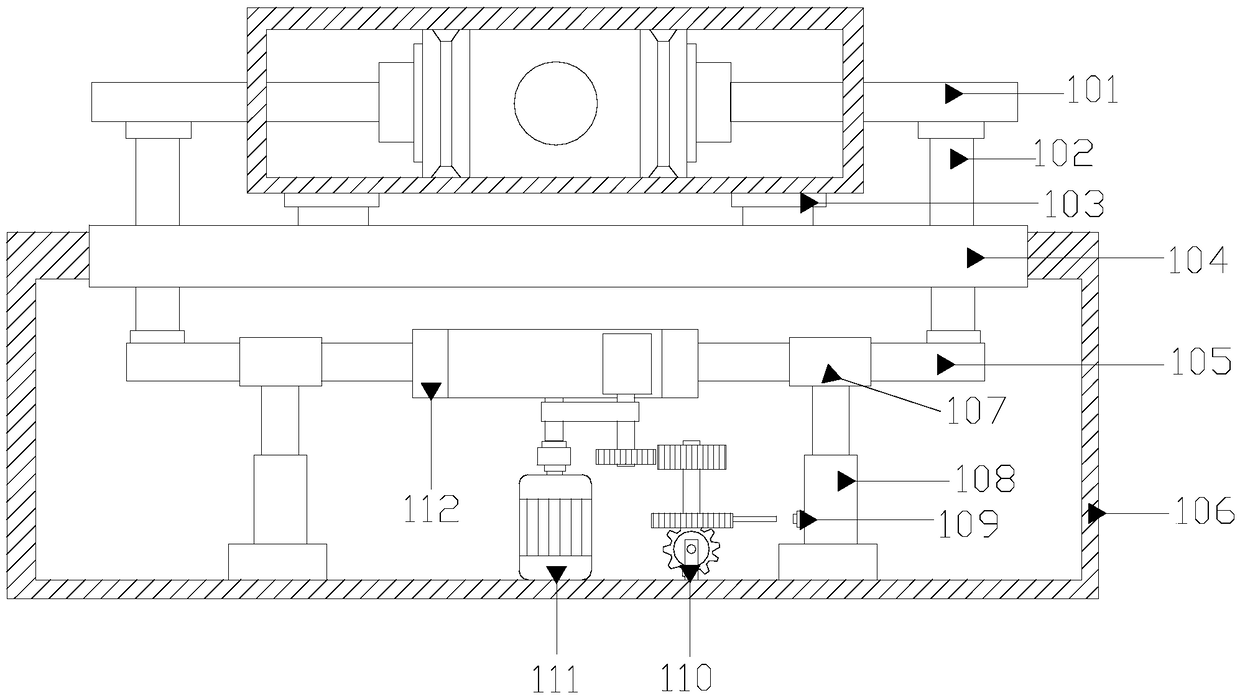

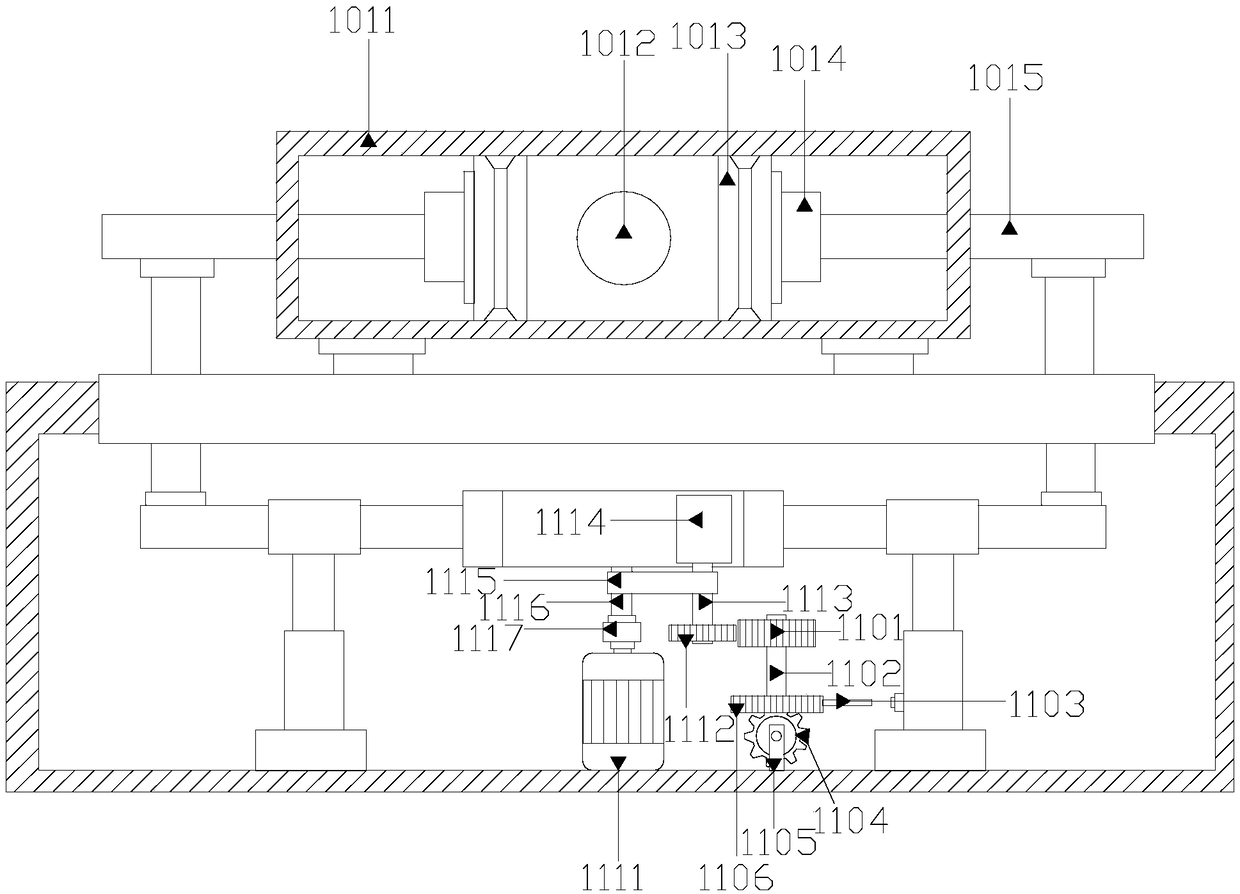

[0022] Such as Figure 1-Figure 5 As shown, the present invention provides a material diversion device for plastic molds, and its structure includes a quick and convenient diversion mechanism 1, a support plate 2, a diversion trough body 3, a clamping plate 4, a first water inlet pipe 5, a diversion plate body 6, and a guide Through the box body 7, the bracket plates 2 are provided with two, the bracket plates 2 are respectively welded to the two ends of the quick and convenient shunt mechanism 1 and fixedly connected by positioning pins, and the clamping plate 4 is fixed and welded to the quick and convenient shunt mechanism 1 The front end and the two are integrally formed. The bottom of the conduction box 7 is fixed on the upper end of the clamping plate 4 and is in contact with the quick and convenient shunt mechanism 1, and the upper end of the shunt tank body 3 is fixedly welded to the conduction box. The bottom of the body 7 is connected between the two, the first water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com