Support mechanism for discharge end piece

A discharge end and end piece technology, applied in the field of the support mechanism of the discharge end piece, can solve the problems of derived energy waste, reduced manufacturing efficiency, and shortened displacement stroke of the discharge end piece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, a preferred embodiment of the present invention will be described in detail together with the drawings.

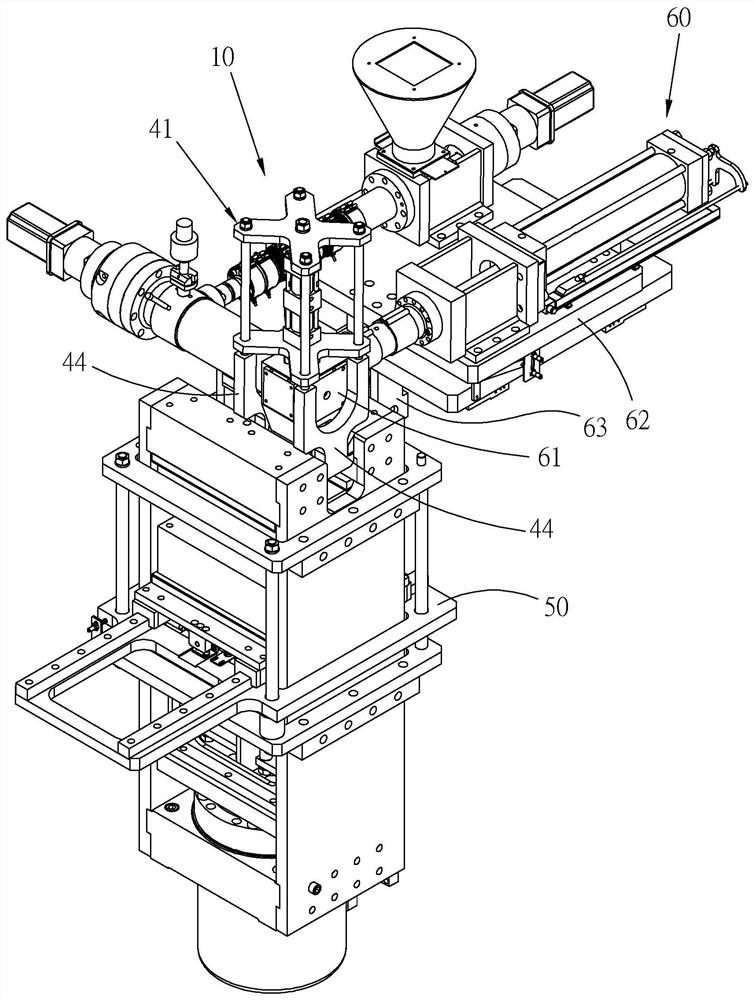

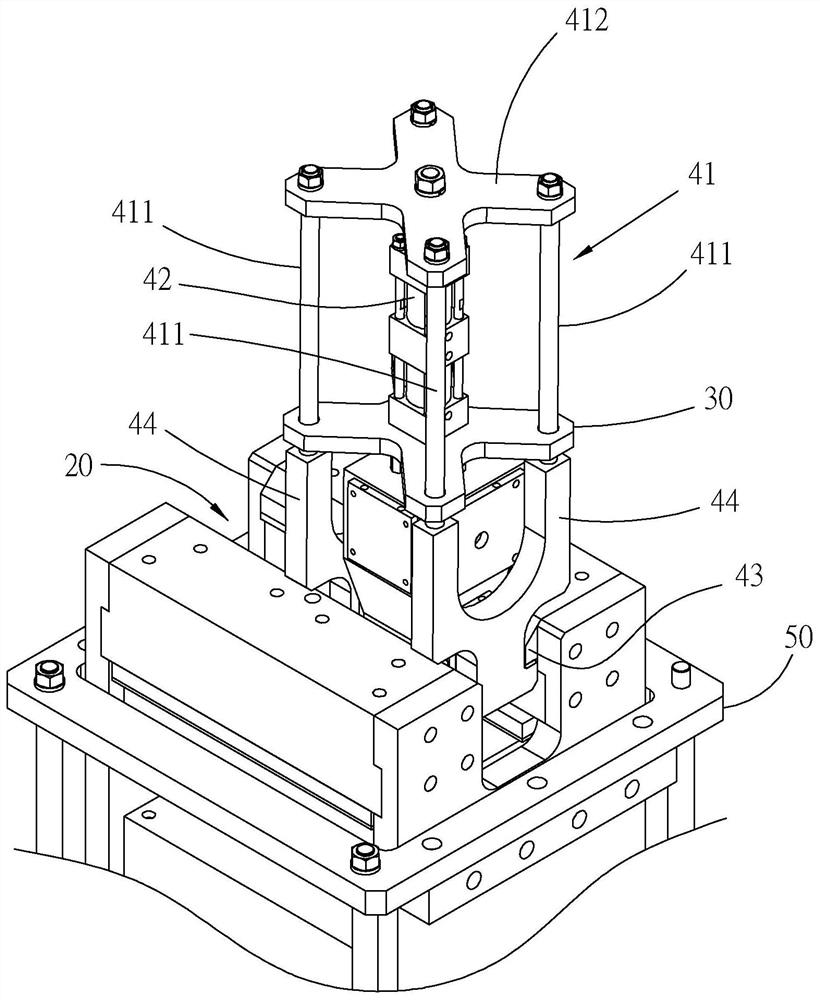

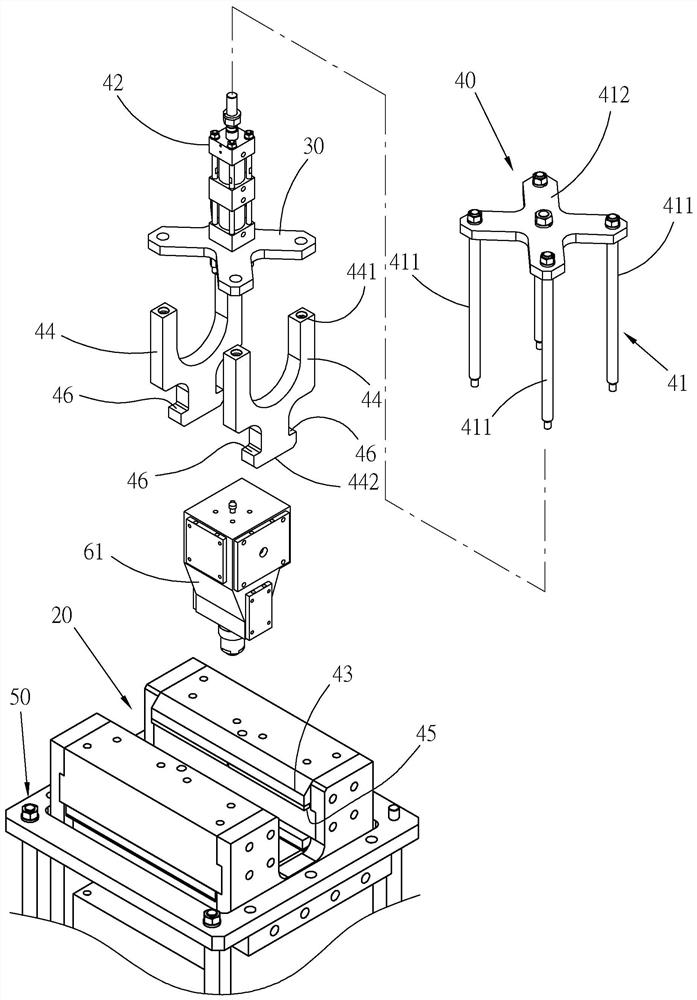

[0032] First, see Figure 1 to Figure 3 As shown, in a preferred embodiment of the present invention, the supporting mechanism 10 of the discharge end piece mainly includes a movable space 20 , a seating portion 30 and a supporting portion 40 .

[0033] The movable space 20 is a groove with an opening facing upwards and two sides are hollow, and is recessed on the top end surface of a clamping mechanism 50 .

[0034] The seat 30 is plate-shaped, and is fixed above a discharge end piece 61 located above the opening of the movable space 20, so that the discharge end piece 61 is interposed between the clamping mechanism 50 and the seat 30 .

[0035] The supporting part 40 has a sliding part 41, which is slidably arranged on the seat part 30, and can move back and forth linearly along the opening direction of the activity space 20, and a driving part 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com