Flexible jacking assembly

A jacking and assembly technology, applied in the direction of lifting devices, motor vehicles, transportation and packaging, etc., can solve problems such as insufficient meshing degree, meshing degree error, gear stuck, etc., to avoid fracture and damage, eliminate stuck, increase The effect of stationarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

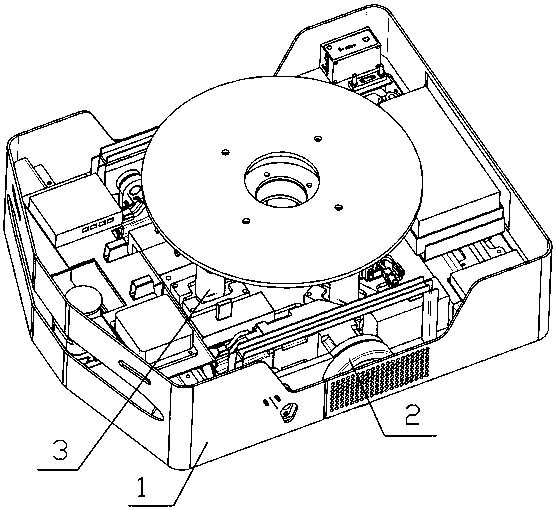

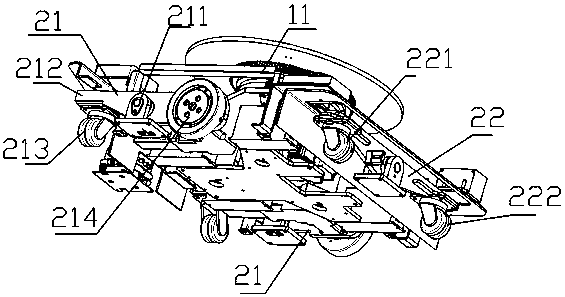

[0024] Example 1, such as figure 1 and figure 2 As shown, a flexible jacking assembly includes a car body 1 and a running device 2 at the bottom of the car body 1 . For the stable and smooth running of the vehicle body, in this embodiment, six wheel bodies are arranged in total, including two driving wheels and four driven wheels, and these four driven wheels are universal wheels.

[0025] like figure 2 As shown, a set of drive wheel hinge groups 21 are respectively arranged on the left and right sides of the vehicle body 1. Each drive wheel hinge group 21 includes a hinge support shaft 211 and a hinge support 212. The hinge support shaft 211 is connected to the vehicle body 1. And the middle position of hinge support 212 is hinged with hinge support shaft 211, can swing up and down with hinge support shaft 211 as the fulcrum two ends, and auxiliary wheel 213 and drive wheel 214 are installed respectively at the two ends of hinge support 212. In this way, the auxiliary wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com