Tunnel-strode support large-span stand column device

A large-span, column technology, used in excavation, construction, infrastructure engineering, etc., can solve the problems of small spacing and high density, and achieve the effect of increasing the spacing of column piles and reducing the number of column piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

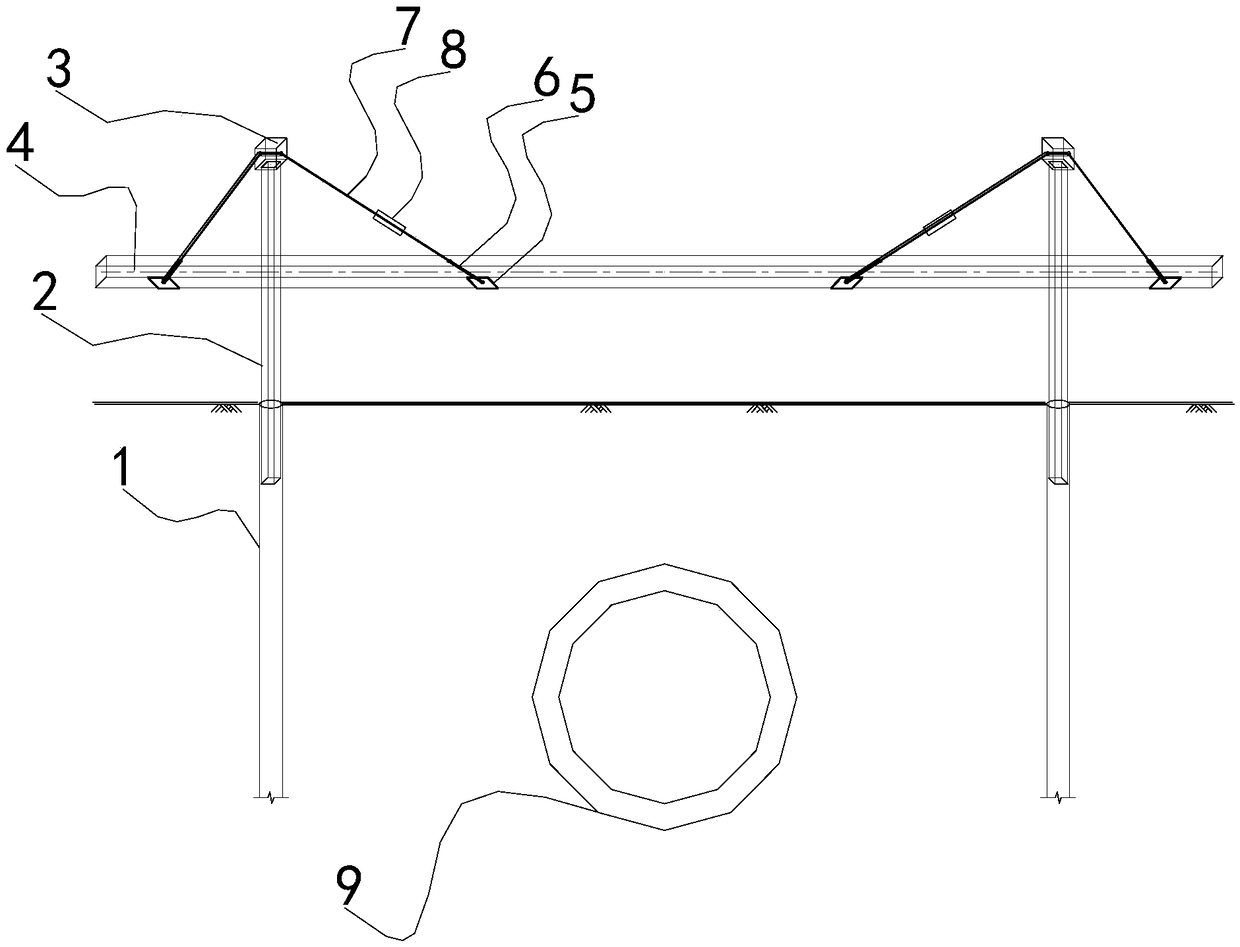

[0019] figure 1 It is a cross-sectional layout diagram of a medium-span tunnel supporting a large-span column device in Embodiment 1.

[0020] Such as figure 1 As shown, in this embodiment, the large-span column device for cross-tunnel support is arranged above the underpass tunnel 9 to realize the function of avoiding the underground tunnel 9 to be built below the bottom of the foundation pit.

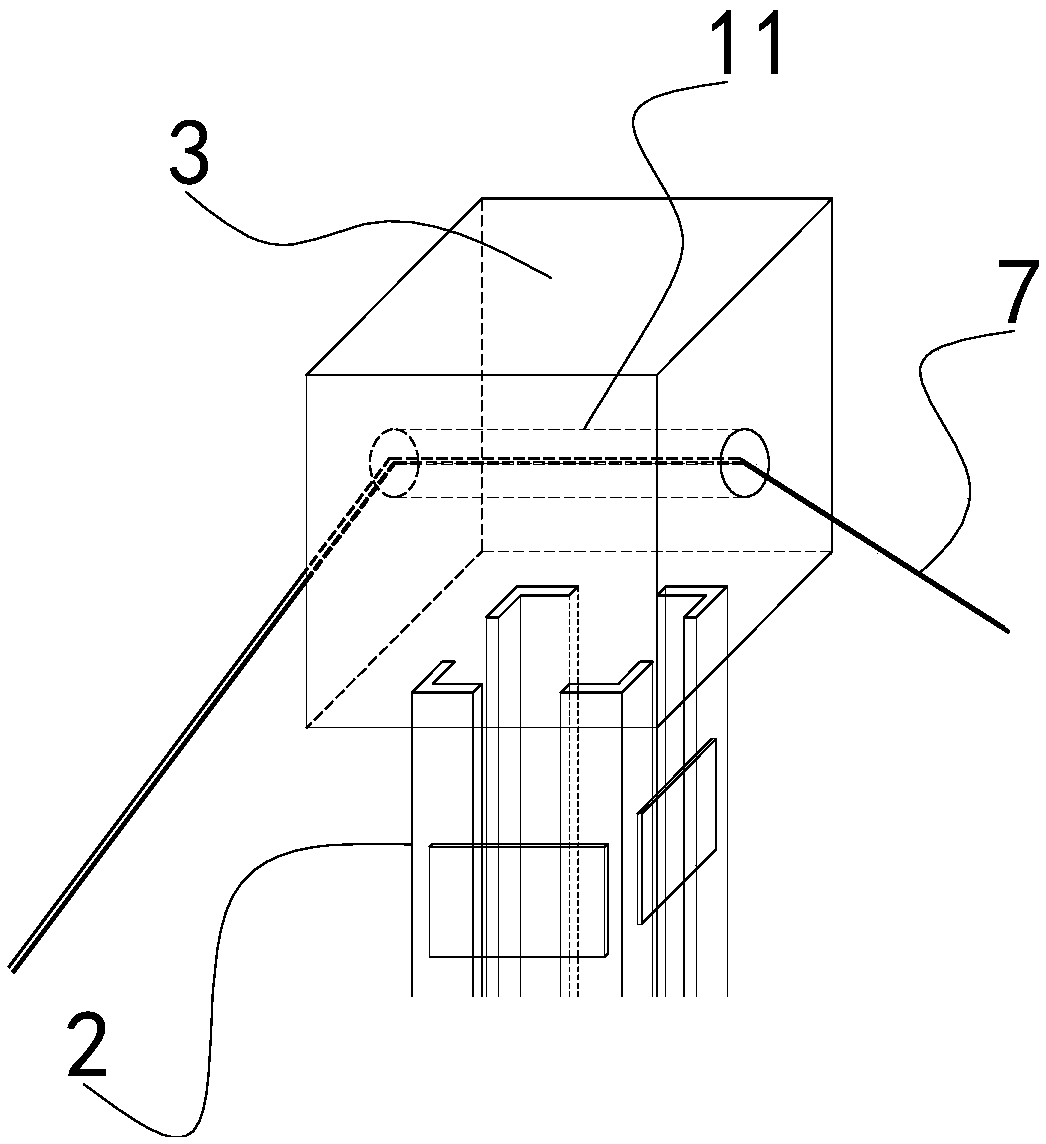

[0021] The device for supporting large-span columns across the tunnel, including: two column pouring piles 1, two column lattice columns 2, two lattice column caps 3, concrete support 4, two steel strands 7, and four support anchor plates 5 and two strand tighteners 8.

[0022] The column lattice column 1 corresponds to the column cast-in-place pile 2 one by one; the lower part of the column lattice column 2 and the steel cage on the upper part of the column cast-in-place pile 1 are welded and fixed, and they are lowered into place together when the column pile is constructed. The ...

Embodiment 2

[0031] In this embodiment, the large-span column device supported across the tunnel, except that the lattice column cap structure is different from that of Embodiment 1, the structures and working principles of other components are the same as those of Embodiment 1, and will not be described again.

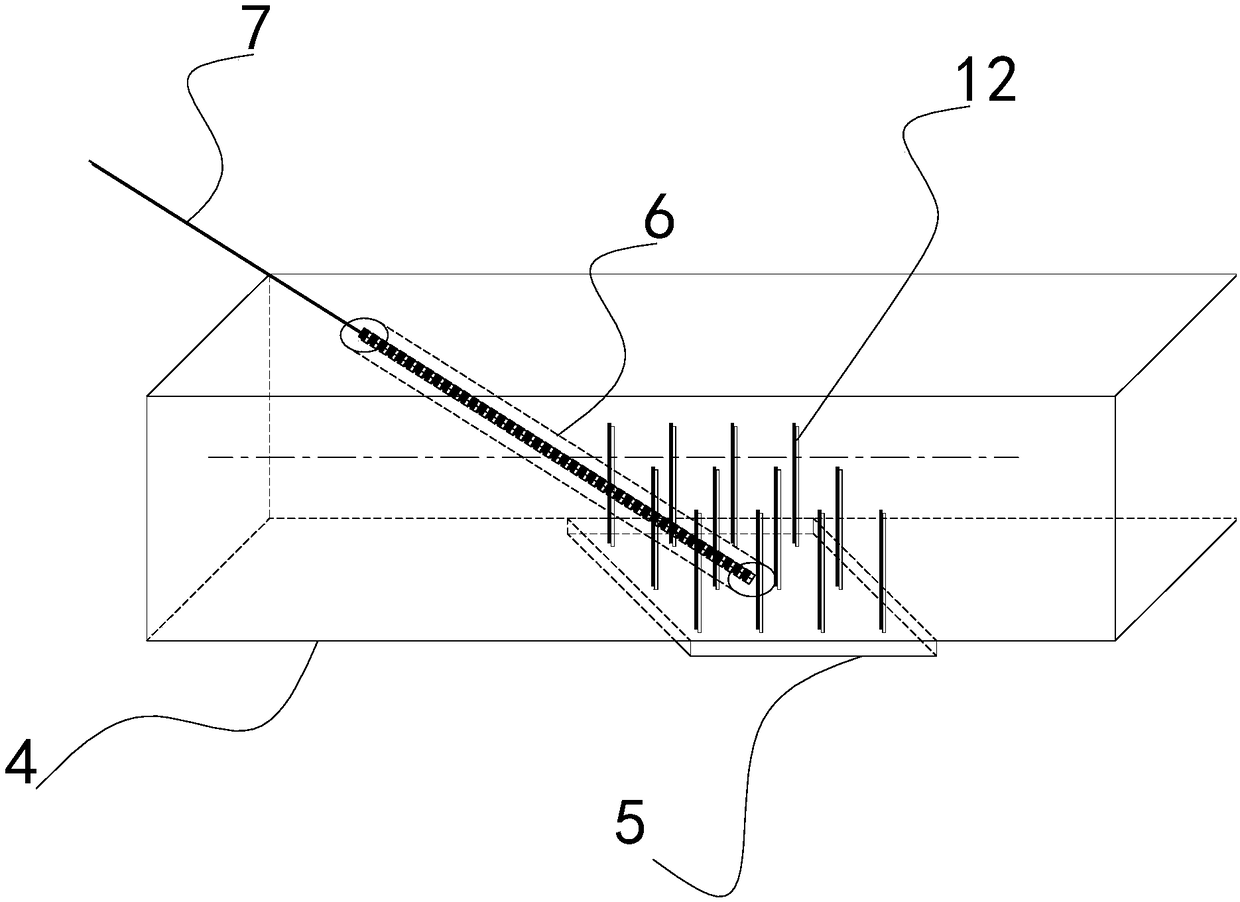

[0032] Figure 4 It is a top half-sectional view of the connection position between the lattice column cap and the steel strand in the second embodiment.

[0033] Such as Figure 4 As shown, in this embodiment, three rollers 13 are also arranged in the hole 11 for the twisted wire of the lattice column cap 3 to pass through. Have groove on the roller shaft 13, and can rotate. The steel strand 7 is embedded in the groove; and is arranged parallel to the concrete support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com