Integral concrete falling plate and construction method thereof

A technology of concrete and lowering slabs, which is applied to floors, buildings, building components, etc., can solve problems such as difficult operation and complicated construction, and achieve the effects of improving impermeability, improving construction efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

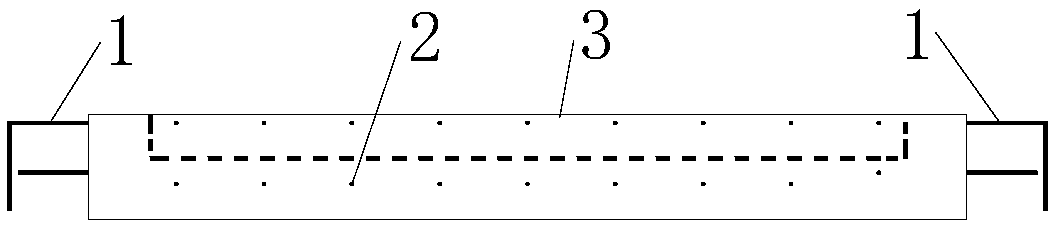

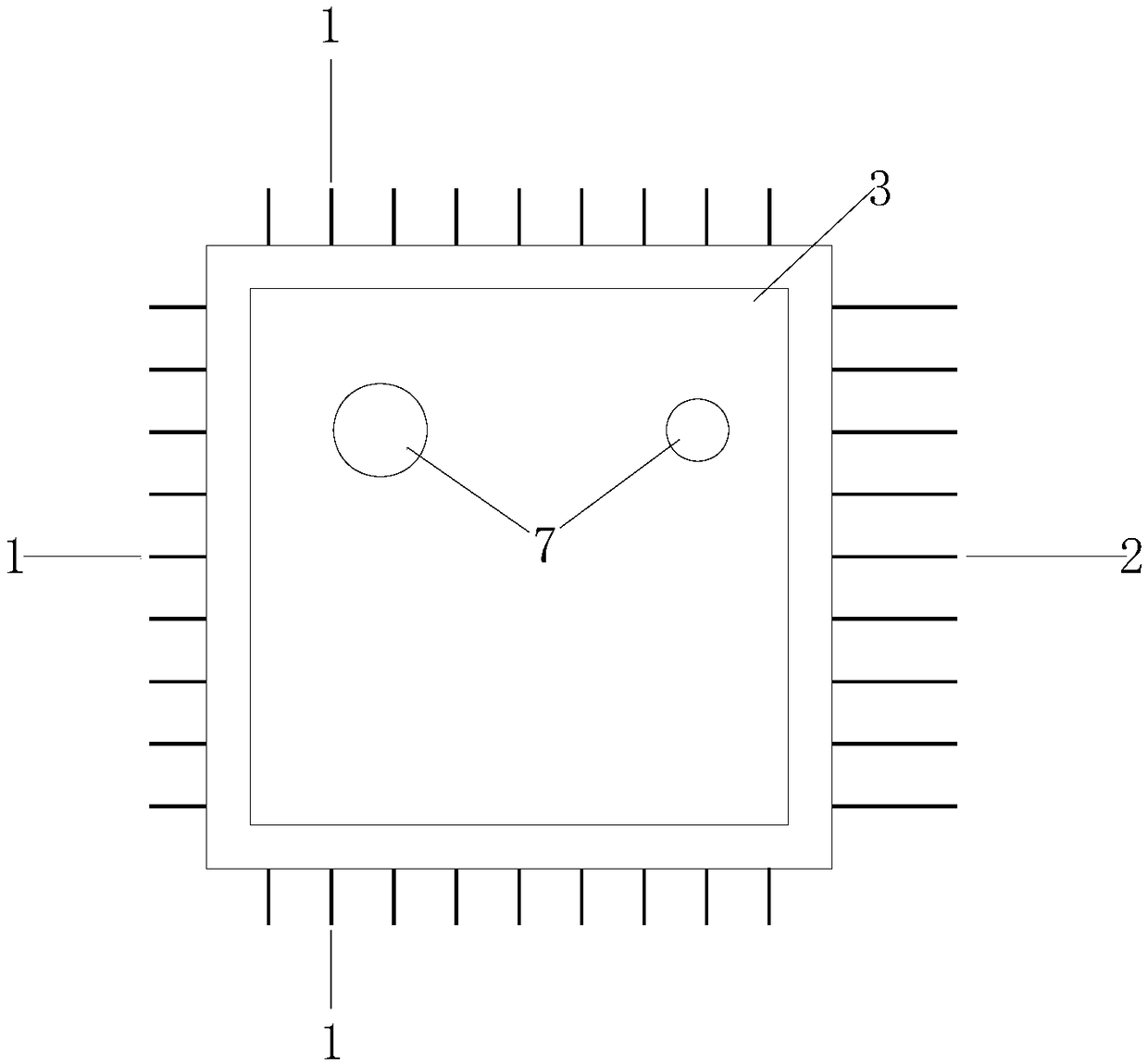

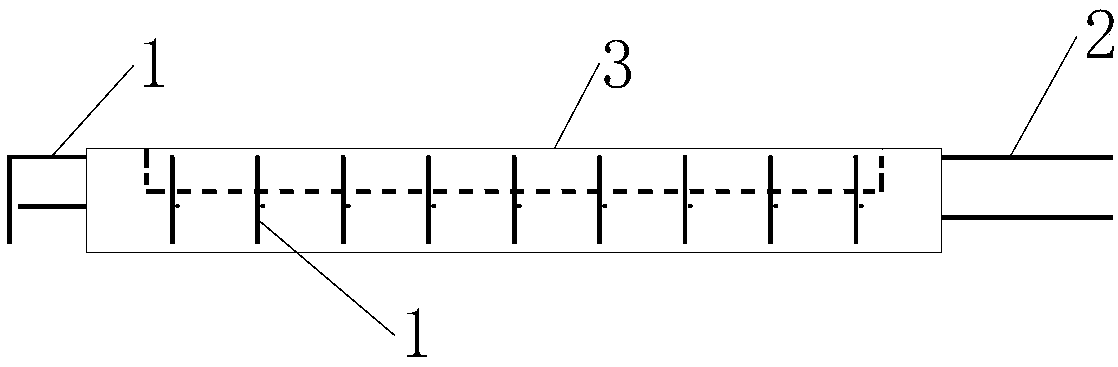

[0020] Such as Figure 1-5 Shown, a kind of concrete descending slab, it is equipped with reserved line hole pipe on its slab surface, it is characterized in that: it is the integral concrete slab 3 of prefabrication, is provided with anchoring steel bar all around, wherein three sides are anchoring steel bar-1, and one side is anchoring steel bar. Reinforcing bar two 2, described anchoring reinforcing bar one 1 is the right angle that bends and disassembles downwards, and the side where anchoring reinforcing bar one 1 is located is fixedly connected with body of wall 4; Described anchoring reinforcing bar two 2 is the reinforcing bar stretching out straight, anchoring reinforcing bar two 2 The side where it is located is fixedly connected with another prefabricated laminated floor slab 5 .

[0021] The lowering slab of this scheme is a prefabricated structure, and the loweri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com