A method for counteracting circumferential friction of double-layer drill pipe and double-layer drill pipe

A double-layer drill pipe, hexagonal technology, applied in drill pipe, drill pipe, earthwork drilling, etc., can solve the problem of low drilling trajectory control accuracy in broken and soft coal seams, ensure safe and efficient mining, and improve coal seam drilling rate , the effect of avoiding the blind spot of drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for counteracting the circumferential friction of a double-layer drill pipe. In this method, a TC bearing and an external gear bushing are arranged coaxially between the outer pipe and the inner pipe assembly of the double-layer drill pipe. When the outer pipe rotates At the same time, the TC bearing and the outer gear sleeve produce circumferential friction in the opposite direction to the inner pipe assembly, thereby offsetting the circumferential friction of the double-layer drill pipe; The TC bearing is arranged between the hexagonal joint and the end of the inner pipe body, and the outer gear shaft is sleeved between the hexagonal sleeve and the end of the inner pipe body; the outer gear sleeve can be connected with the outer The tube rotates in reverse.

[0041] Specifically, the rotation of the outer tube can drive the TC bearing to rotate, and the rotation of the TC bearing causes the inner tube assembly to generate circumferent...

Embodiment 2

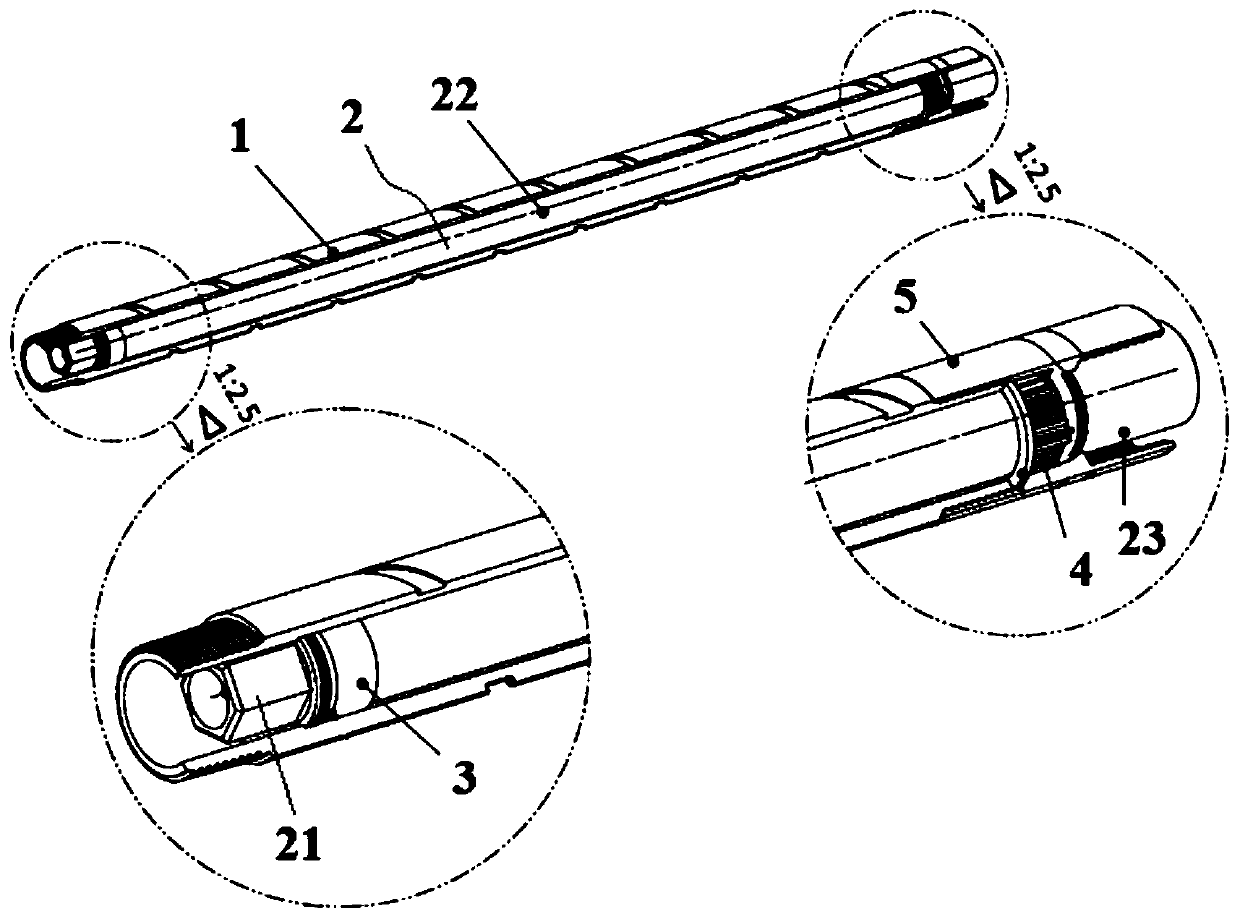

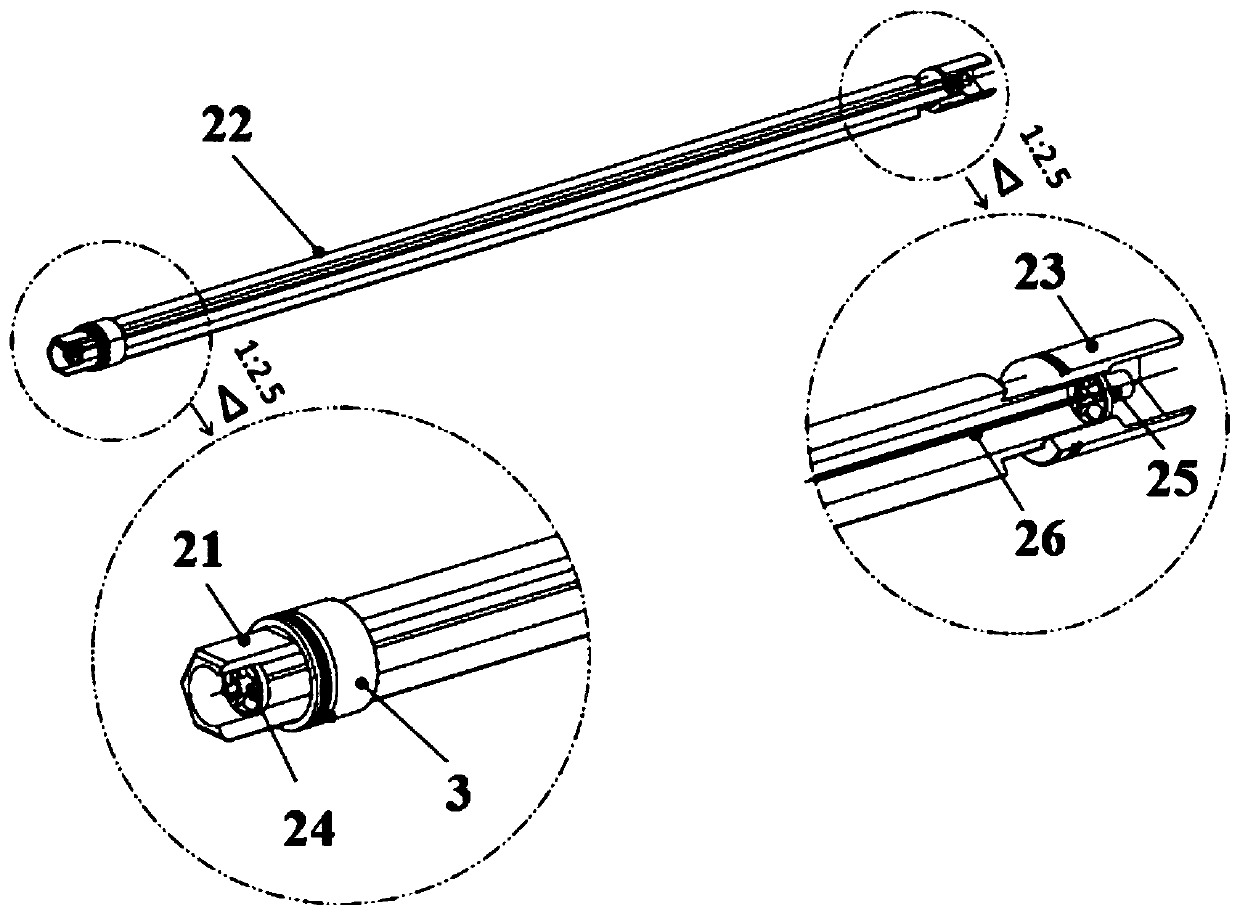

[0044] like Figure 1 to Figure 6 As shown, this embodiment provides a double-layer drill rod, which can realize the above-mentioned method of offsetting the circumferential friction of the double-layer drill rod. Into 2, TC bearing 3 and outer gear bushing 4 are arranged coaxially between outer pipe 1 and inner pipe assembly 2; inner pipe assembly 2 includes hexagonal joint 21, inner pipe body 22 and hexagonal The sleeve 23 and the TC bearing 3 are arranged between the hexagonal joint 21 and the end of the inner pipe body 22, and the outer gear sleeve 4 is arranged between the hexagonal sleeve 23 and the end of the inner pipe body 22;

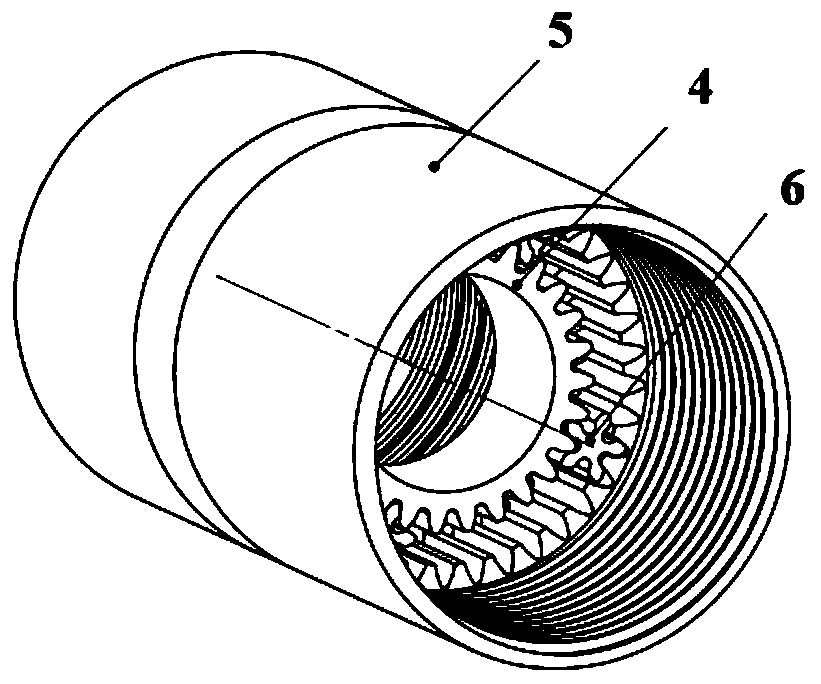

[0045] The end of the outer tube 1 is connected with an internal gear joint 5 , and a planetary gear 6 meshing with the gears of the internal gear joint 5 and the external gear sleeve 4 is arranged between the internal gear joint 5 and the external gear sleeve 4 .

[0046] In this embodiment, the inner pipe assembly 2 includes a hexagonal joi...

Embodiment 3

[0060] This embodiment provides a drilling system, which includes a plurality of double-layer drill rods described in Embodiment 2; the drilling system also includes a flexible internal control rotary directional drilling tool, an orientation system, a drill bit and a dual power head Drilling machine; the directional system includes an upper non-magnetic drill rod, a lower non-magnetic drill rod, an outer probe tube, and a measurement probe tube, and the measurement probe tube is connected to the mandrel of a flexible internal control rotary directional drilling tool through a transition inner tube; The outer pipe at the bottom of the double-layer drill pipe hole is connected to the upper non-magnetic drill pipe, and the inner pipe is connected to the measuring probe through the transition inner pipe. The double-layer drill pipe extends from the rear end of the non-magnetic drill pipe at the bottom of the hole to the hole At the dual power head drilling rig. The drilling syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com