A propulsion system for automatic distribution of shield anti-eccentric load

A propulsion system and automatic distribution technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve problems such as difficulties, and achieve the effects of uniform thrust, enlarged geological application range, and uniform distribution characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with examples and accompanying drawings.

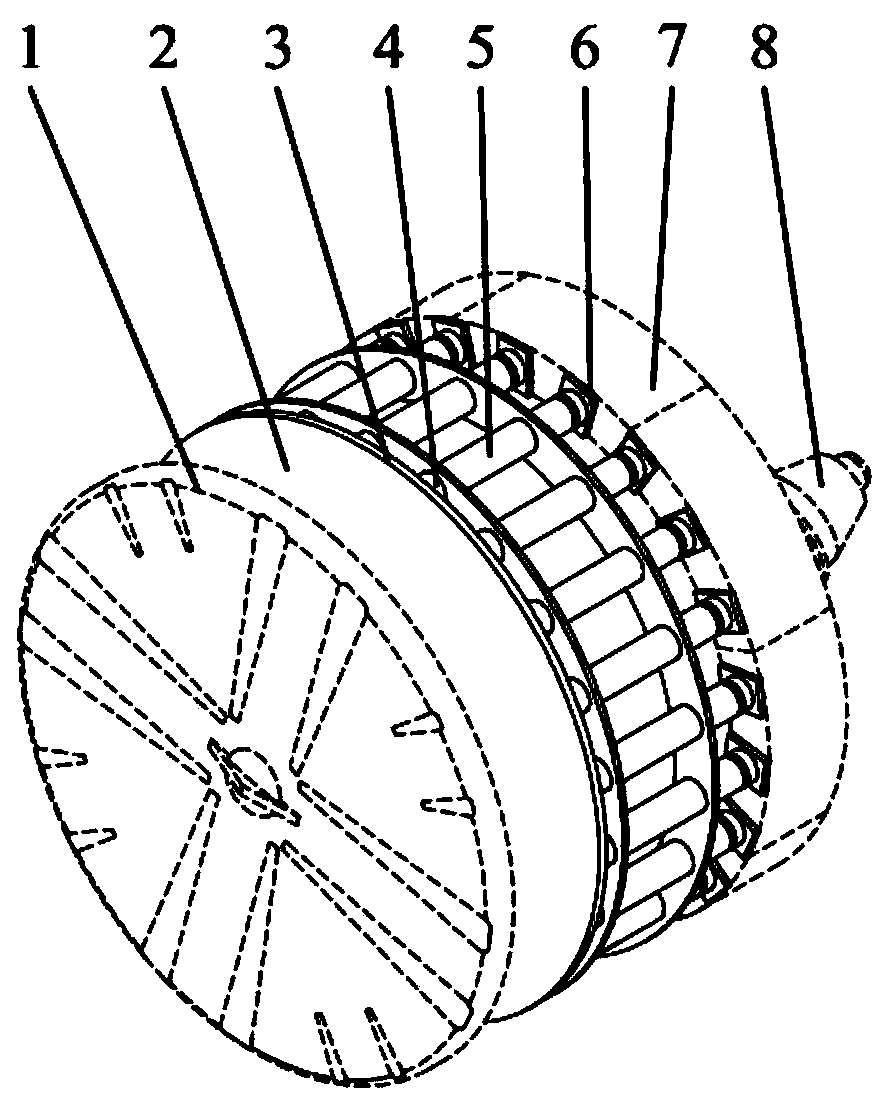

[0022] Such as figure 1 As shown, it mainly includes a cutter head 1, a shield body 2, a circular partition 3, a hydraulic control valve 4, a hydraulic cylinder 5, a pressure-resistant hard rubber block on the circular partition 3, and a hydraulic reversing valve on the hydraulic cylinder 5. 4 Control expansion and contraction, the left end of the hydraulic cylinder 5 is lined with a pressure-resistant hard rubber block and the circular partition 3 is fixed, the right end is pushed on the segment (7) through the support shoe (6), and the cutter head 1 cuts rocks and soil through the spiral Conveyor 8 conveys out, and the right end of hydraulic cylinder 5 pushes on segment 7 by support shoe 6.

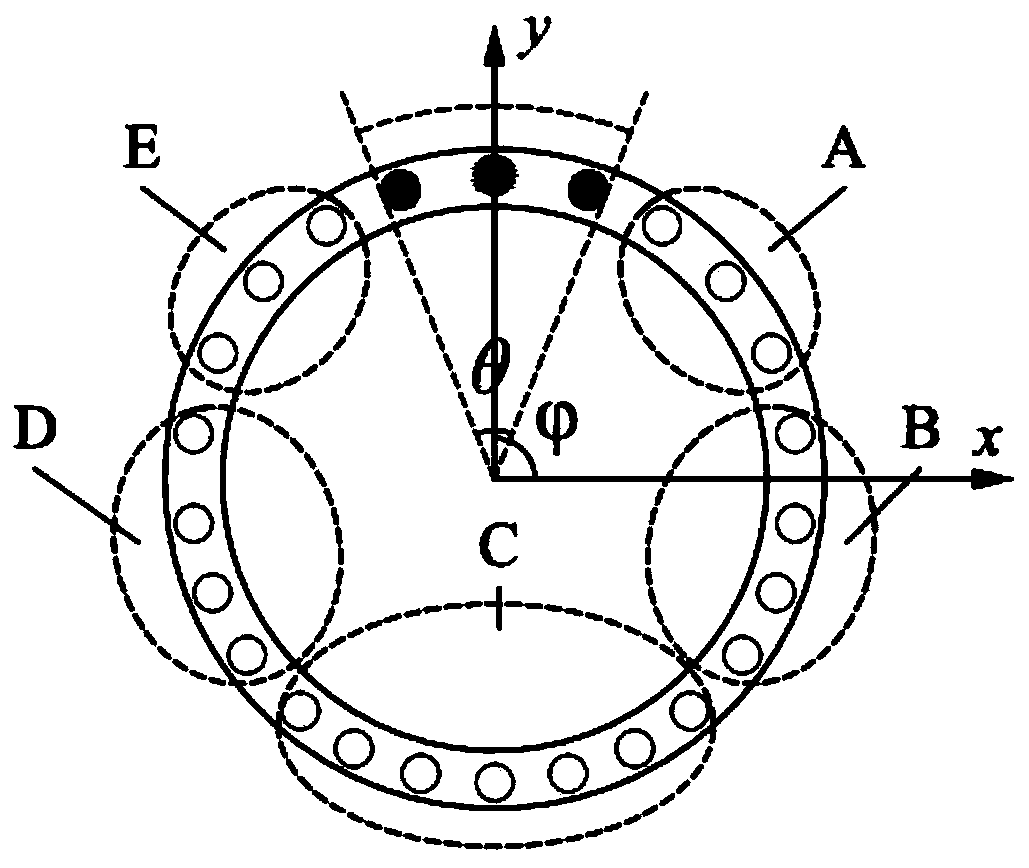

[0023] Such as figure 2 As shown, several hydraulic cylinders are arranged in a ring, equidistant, continuous and uniform on the system, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com