Variable-injection-rate injection system and method of dual-common-rail mechanical fuel injector for diesel engine

A mechanical fuel injection and injection system technology, applied in mechanical equipment, fuel injection control, machine/engine, etc., can solve problems such as not being able to meet the best requirements of the engine, reduce design difficulty, improve reliability, and achieve fuel consumption and emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

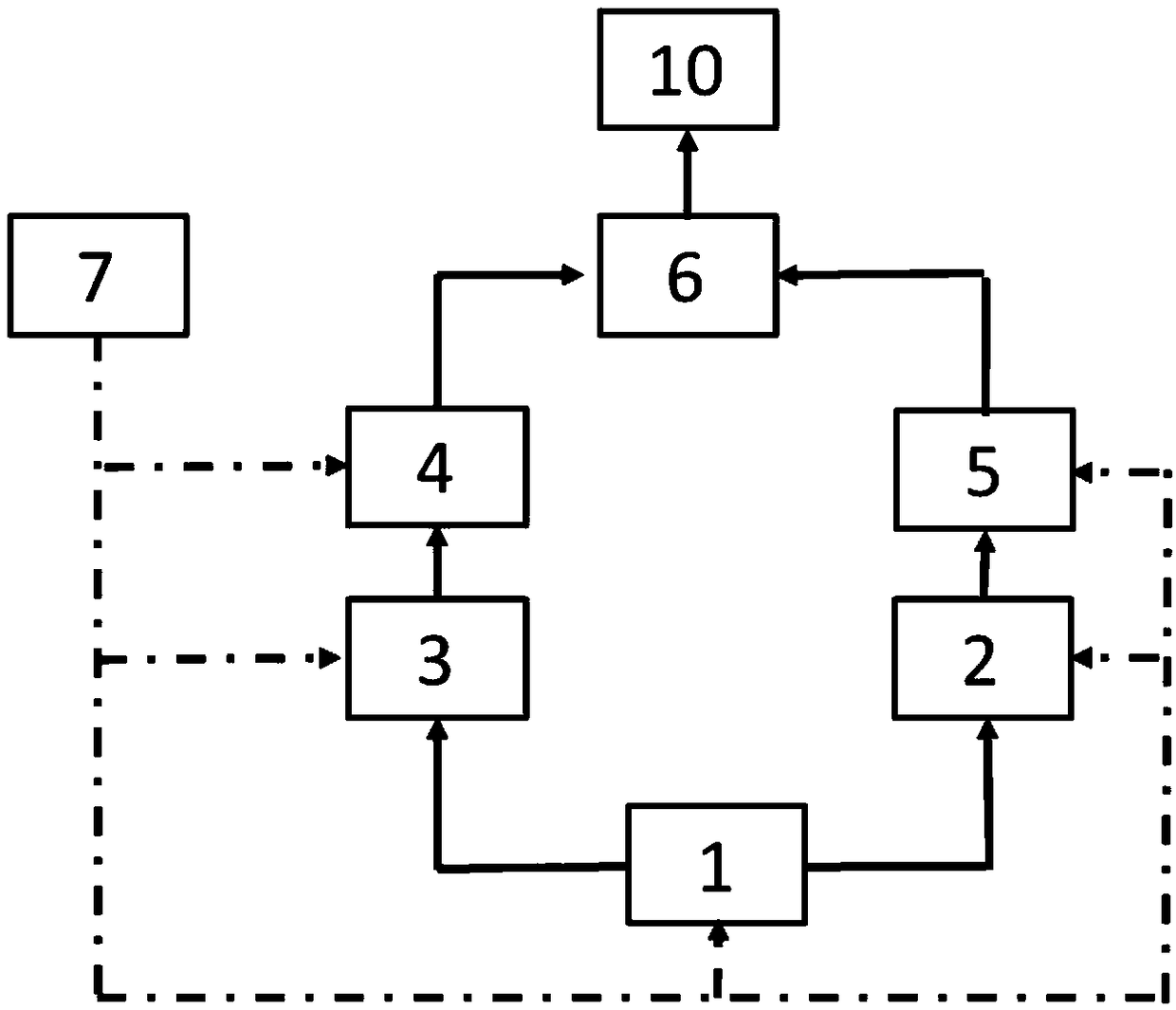

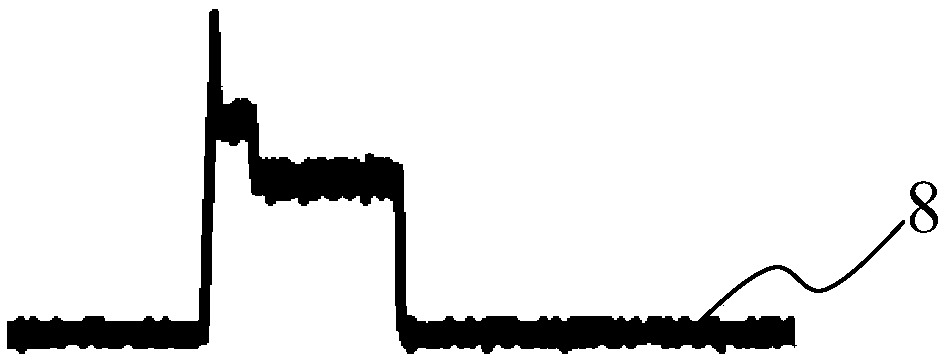

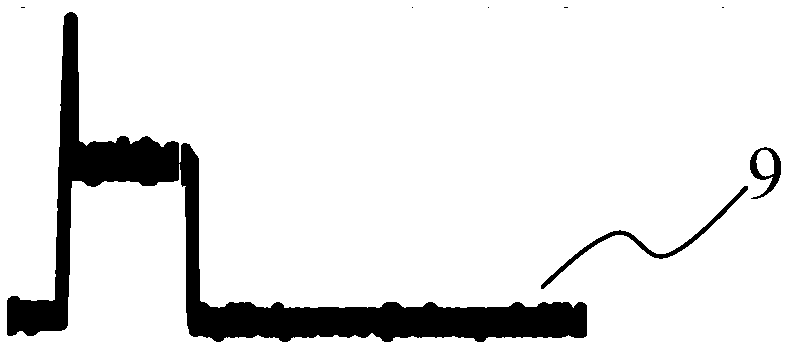

[0032] Embodiment 1: the low-pressure oil rail 2 establishes a pressure of 400 bar under the action of the high-pressure oil pump 1, and the high-pressure oil rail 3 establishes a pressure of 1000 bar under the action of the high-pressure oil pump 1. The electronic control unit ECU7 controls the electronically controlled fuel injector 15 to open it after 1000 us and close it. At the same time, the electronic control unit ECU7 electronically controlled fuel injector Ⅱ4 is turned on for 1000us and then turned off.

Embodiment 2

[0033] Embodiment two: the low-pressure oil rail 2 establishes a pressure of 1000 bar under the action of the high-pressure oil pump 1, and the high-pressure oil rail 3 establishes a pressure of 2400 bar under the action of the high-pressure oil pump 1. The electronic control unit ECU7 controls the electronically controlled fuel injector 15 to open it after 3000us and close it. At the same time, the electronic control unit ECU7 electronically controlled fuel injector Ⅱ4 is turned on for 2000us and then turned off.

Embodiment 3

[0034]Embodiment three: the low-pressure fuel rail 2 establishes a pressure of 700 bar under the action of the high-pressure oil pump 1, and the high-pressure oil rail 3 establishes a pressure of 1600 bar under the action of the high-pressure oil pump 1. The electronic control unit ECU7 controls the electronically controlled fuel injector 15 to open it after 2000 us and close it. At the same time, the electronic control unit ECU7 electronically controlled fuel injector Ⅱ4 is turned on for 1500us and then turned off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com