Pump structure and compressor

A pump body, gas pressure technology, applied in the field of compressors, can solve the problem of slow valve opening and closing, and achieve the effect of optimizing the exhaust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

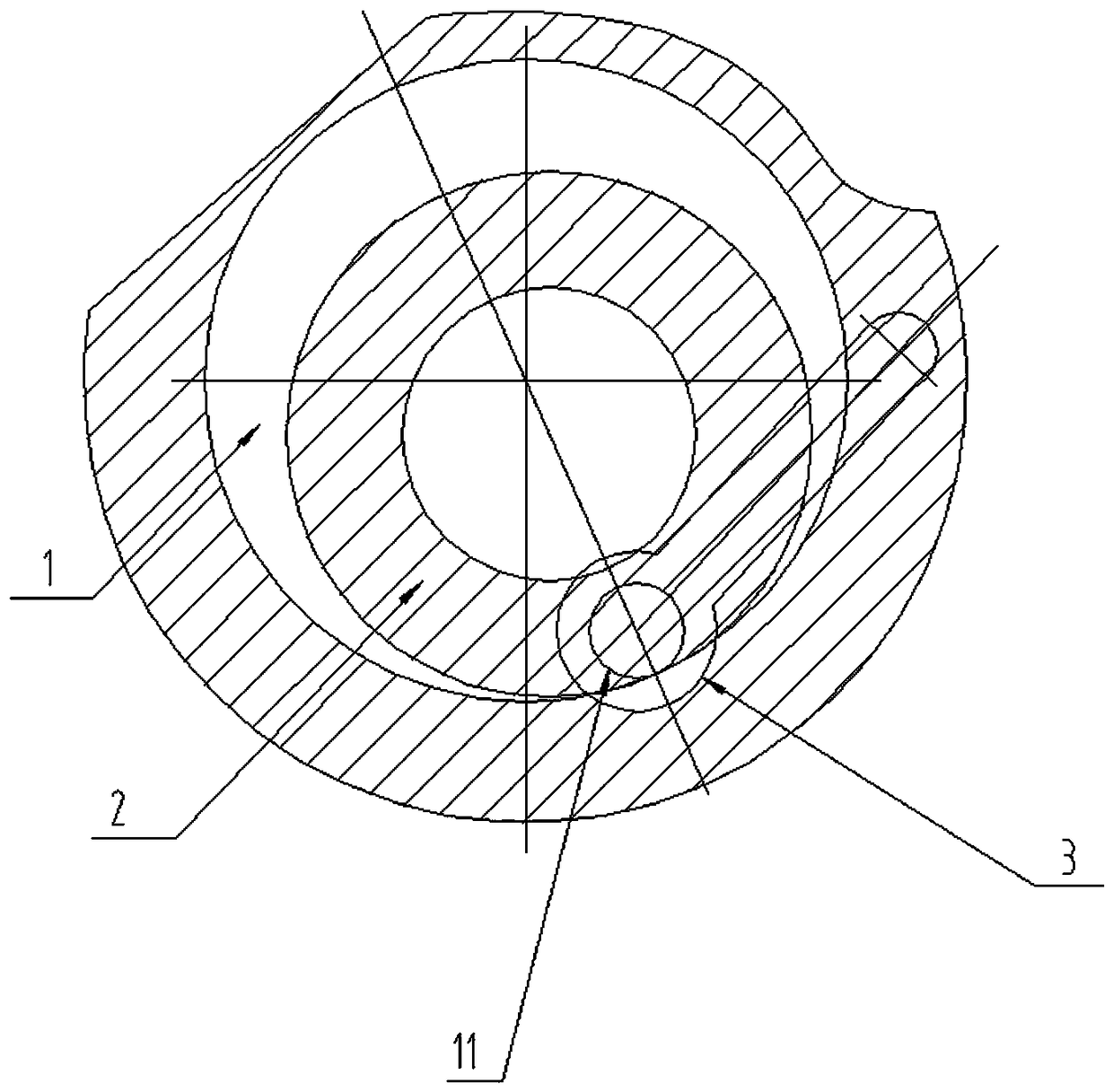

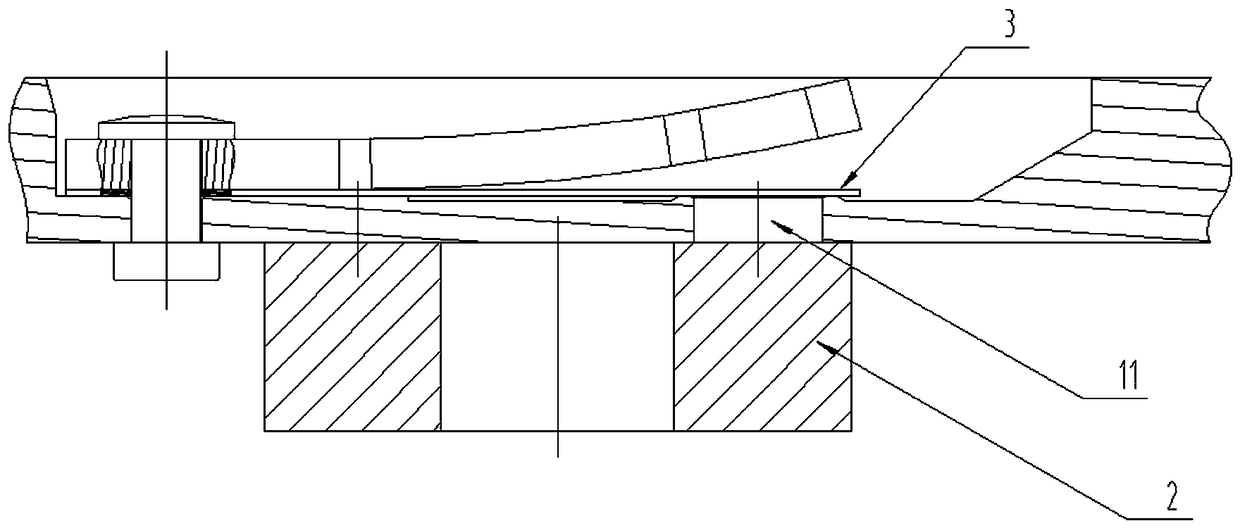

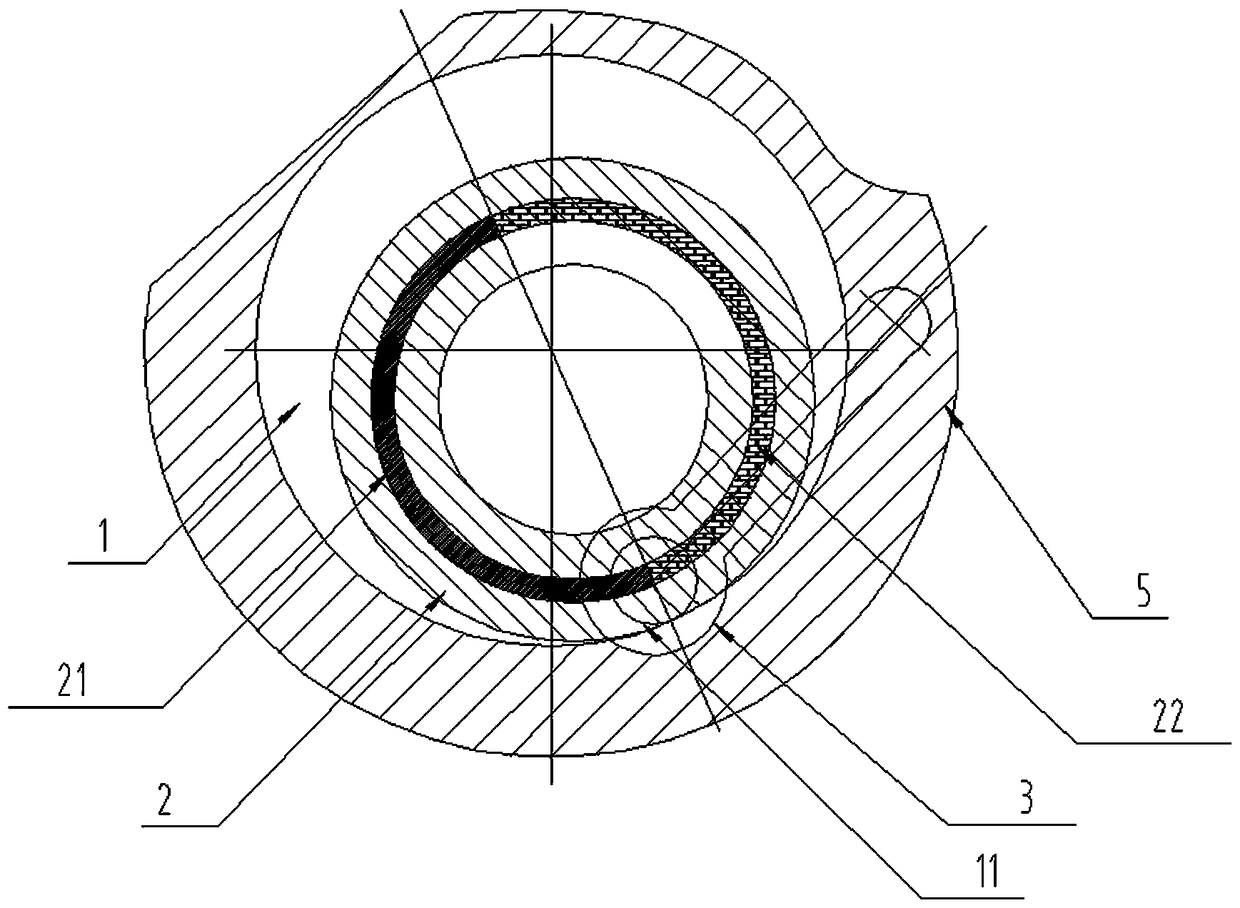

[0025] Such as Figures 3 to 5 As shown, the pump body structure proposed by the present invention includes: a working chamber 1, a roller 2 and a valve plate 3, the working chamber 1 is a cylindrical cavity, the end face of the working chamber 1 is provided with an exhaust hole 11, and the valve plate 3 is installed Outside the working chamber 1 , it is used to control the on-off state of the exhaust hole 11 . The area covering the exhaust hole 11 on the valve plate 3 is provided with a mounting hole, and a magnetic piece 31 is fixed in the mounting hole. The roller 2 is located in the working chamber 1. The shape of the roller 2 is circular. The outer circular surface of the roller 2 rolls along the wall of the working chamber 1. The end surface of the roller 2 near the exhaust hole 11 is provided with a magnetic strip. Group, roller 2 is provided with installation groove near the end face of exhaust hole 11, and magnetic stripe group is fixed in the installation groove, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com