Method for improving medium-length hole blasting effect

A technology of deep hole blasting and blasting hole, which is applied in mine blasting and mining fields, can solve the problems of small charge amount, easy generation of large blocks at the bottom, and large charge amount, etc., and achieve the effect of improving blasting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

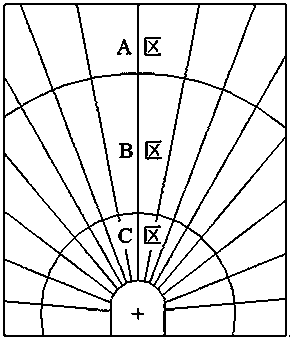

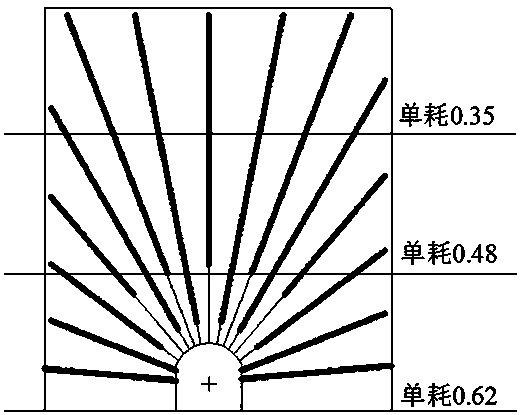

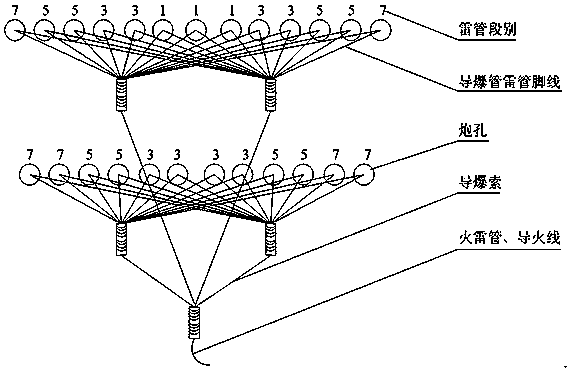

[0013] The present invention is suitable for medium and deep hole mining height and mining width of about 15m for charge arrangement, and blastholes are arranged fan-shaped. The density of blastholes is expressed by the ratio of unit blasthole length to burden area. From figure 1 Area A in the middle is the boundary area of the mining width, and the concentration of blast holes is 0.37; the concentration of blast holes in the central area of area B is 0.52; area C is the area of blast hole openings, and the density of blast holes is 1.47. It can be seen that the density of blastholes gradually decreases with the extension direction of blastholes.

[0014] According to the density of holes in each area of the fan-shaped medium and deep holes, the unit consumption of explosives in each area is calculated by the following formula:

[0015]

[0016] In the formula: ρ 1 ——explosive density, kg / m 3 ; L x ——total length of blast holes in each area, m; S x ——The blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com