Ascending and descending plate blank weighing scale

A slab and drop type technology, which is applied in the field of up-lift type slab weighing, can solve the problems of damage to the cooling water of the sensor roller table, inconvenient inspection and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

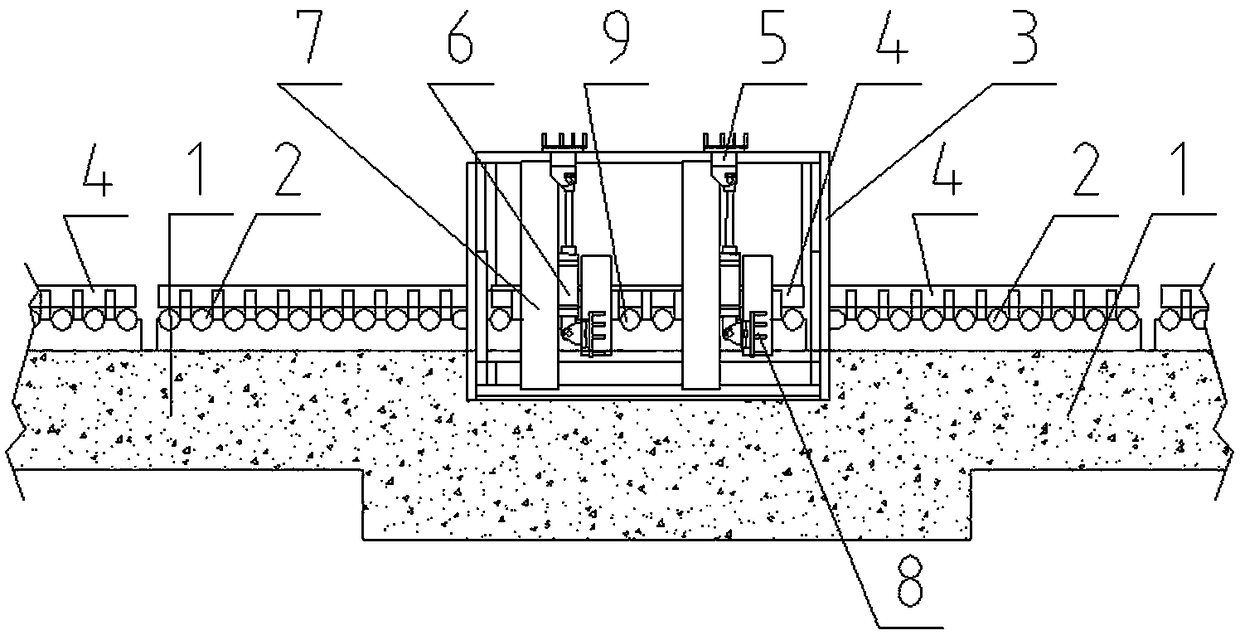

[0008] Such as figure 1 As shown, the liftable slab of the present invention mainly includes a foundation 1, a roller table 2, a lifting frame 3, a fence 4, an oil cylinder 6, and a lifting roller table 9. The lifting roller table 9 between the roller table 2 is upwardly higher than the ground and is equipped with a lifting frame 3, a column 7, a lifting frame 8, and an oil cylinder 6. A gravity sensor 5 is housed between the connection of the column 7 and the oil cylinder 6 . When the lifting roller table 9 descends to the lowest position, it can be connected with the roller table 2 on both sides to transfer the slab. Lifting roller table 9 can freely rise upwards by oil cylinder 6.

[0009] Such as figure 1 As shown, when making and using the present invention, main equipments such as gravity sensor 5, oil cylinder 6 should install corresponding protective equipment for preventing slab high-temperature radiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com