Plate glass high-precision positioning detection working platform

A technology for positioning detection and flat glass, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of increasing the difficulty of operations for operators, the inability to quickly adjust the detection position, and affecting the detection efficiency of flat-edged glass. Achieve the effect of increasing the difficulty of the operation, facilitating the operation and improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

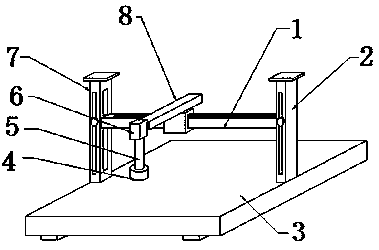

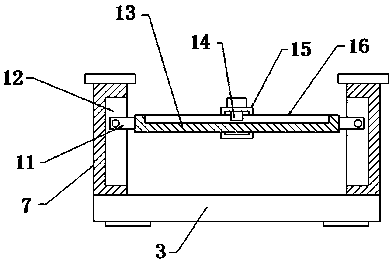

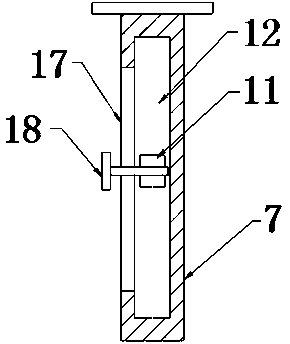

[0021] Specific implementation method: when in use, the operator first places the flat glass to be detected on the upper side of the workbench body 3, and then the operator pushes the support rod 8, and the support rod 8 drives the collar 15 to move on the beam 13, and the collar 15 The movement drives the dovetail slider 14 to move in the dovetail chute 16, and the movement of the beam 13 drives the camera 6, the lens 5 and the light source body 4 to move. When the light source body 4 moves to the top of the flat glass to be detected, tighten the positioning bolt 2, and then The collar 15 is fixed on the beam 13, and then the operator pushes the beam 13 upwards, the beam 13 drives the guide slider 11 to move upward in the guide groove 12, and the guide slider 11 moves upward to drive the positioning bolt 18 to move upward in the front through groove 17 Move, when the crossbeam 13 moves to the specified detection height, the operator tightens the positioning bolt 18, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com