A method of clip defect detection based on depth learning and machine vision fusion

A technology of defect detection and deep learning, which is applied in the direction of optical defect/defect, scientific instruments, instruments, etc., can solve the problem of low detection accuracy, achieve the effect of improving detection accuracy, simple realization, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention are further described below with reference to the accompanying drawings, but the present invention is not limited.

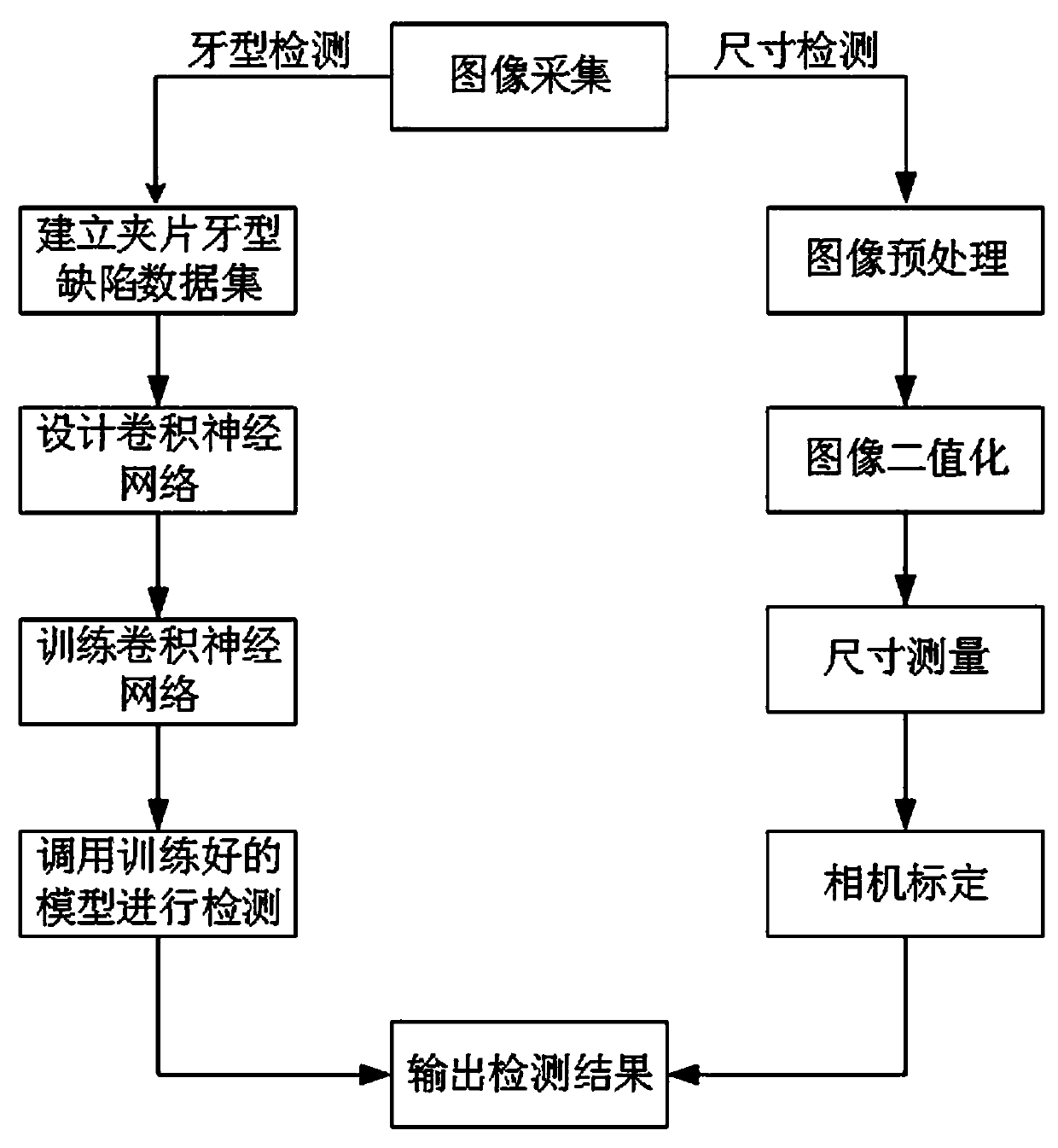

[0034] figure 1 A clip defect detection method based on deep learning and machine vision fusion is shown, including the following steps:

[0035] (1) Image acquisition of the clip workpiece;

[0036] (2) To detect tooth defects on the clips based on the deep learning method;

[0037] (3) Detection of clip size defects based on machine vision;

[0038] (4) Finally, the clip defect detection results are obtained by statistics.

[0039] In step (1), the red bowl lamp is used for illumination, and the dimensional vision MV-VD130 industrial digital camera is used to take pictures and collect, and the image resolution is 1280*1024.

[0040] In step (2), the concrete steps are as follows:

[0041] 1) Establish a clip tooth shape defect data set, which includes flat tooth, rotten tooth, heavy tooth, light pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com