Wood crusher and crushing method

A crusher and crushing mechanism technology, applied in the direction of grain processing, etc., can solve the problems of affecting the work of the crusher, low work efficiency, high processing cost, etc., and achieve the effect of small tool loss, less manpower consumption, and reduced steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

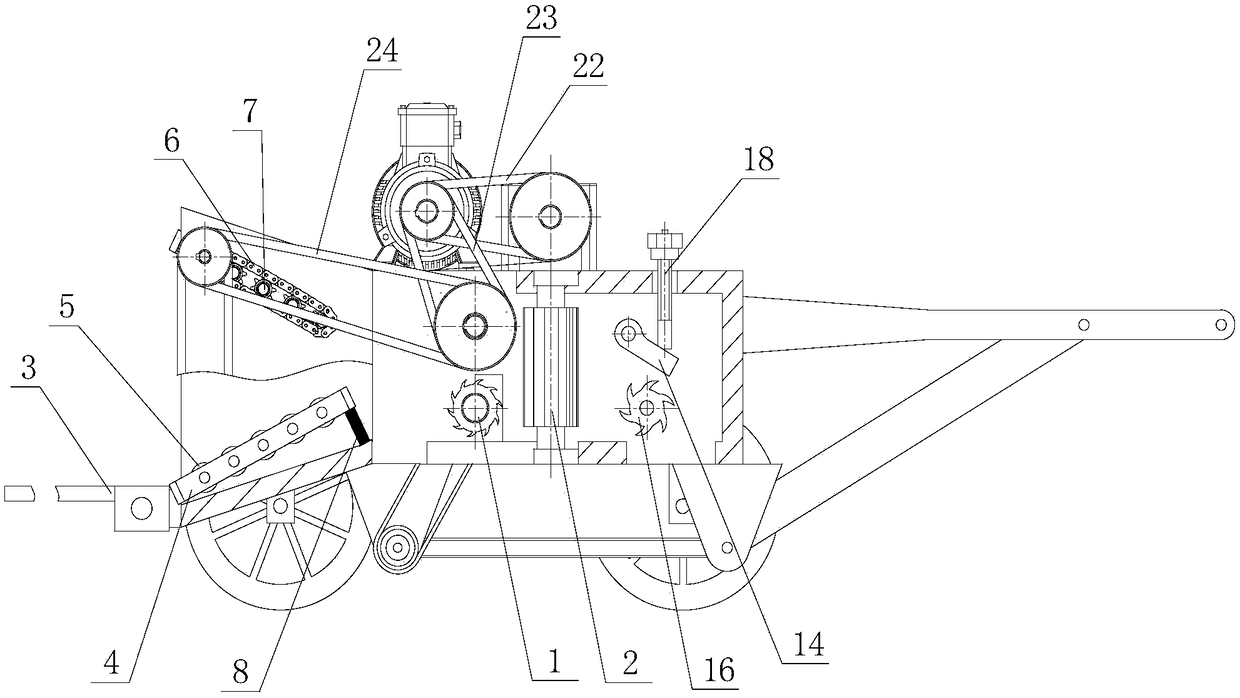

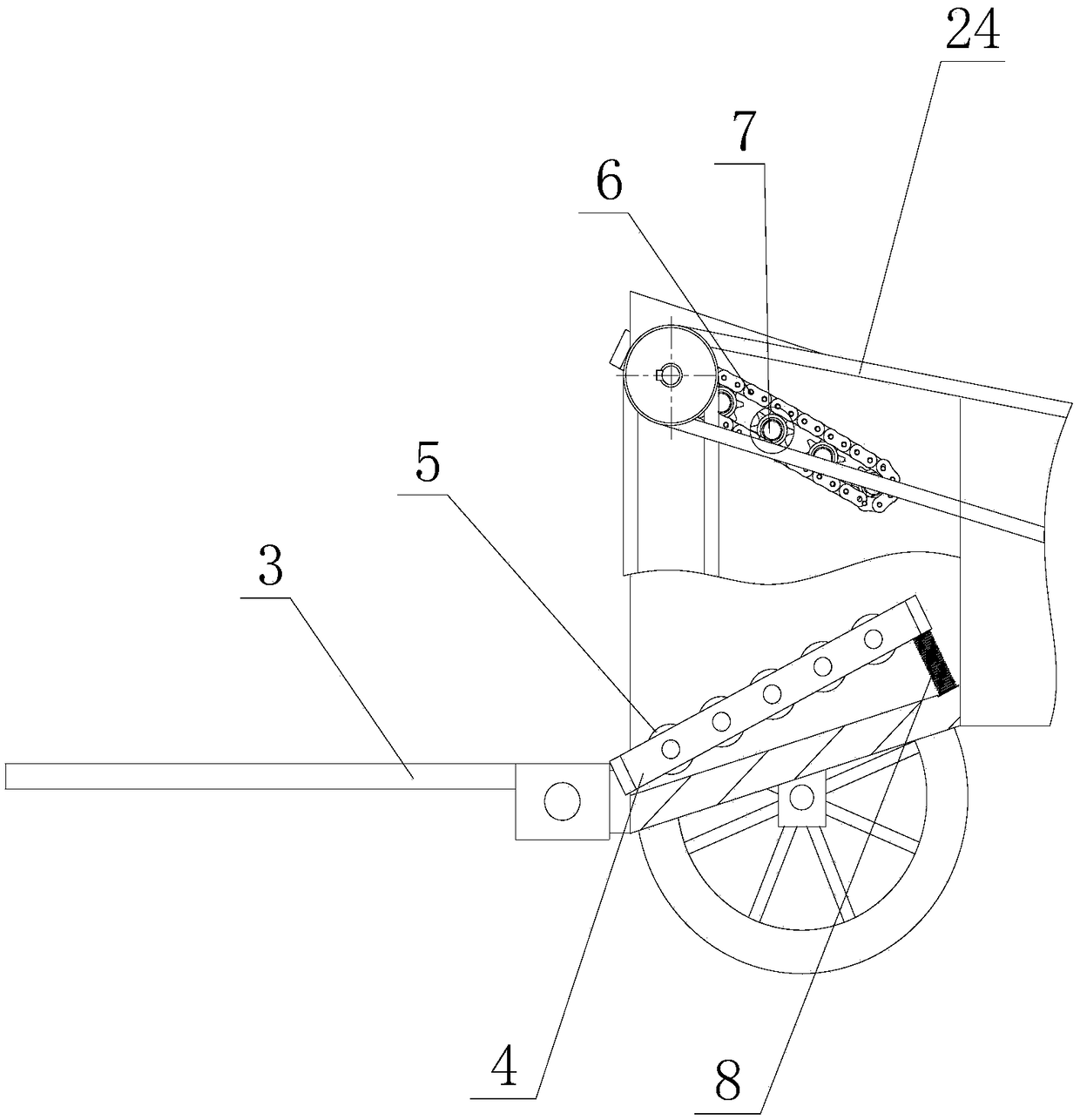

[0033] A wood chipper in this embodiment, such as figure 1As shown, it includes the feeding mechanism, the first crushing mechanism, the second crushing mechanism, the cutting mechanism and the discharging mechanism arranged in sequence along the material conveying direction, and the discharging mechanism is located below the first crushing mechanism, the second crushing mechanism and the cutting mechanism The first crushing mechanism is provided with two matching first hobs, the second crushing mechanism is provided with two matching second hobs, and the first hob and the second hob are vertically arranged; the cutting mechanism Includes matching cutter and baffle. Wherein, each mechanism (including the feeding mechanism, the first crushing mechanism, the second crushing mechanism, the cutting mechanism and the discharging mechanism) is all installed on the frame of the wood crusher. In this embodiment, the material is strip-shaped or stick-shaped logs.

[0034] Such as f...

Embodiment 2

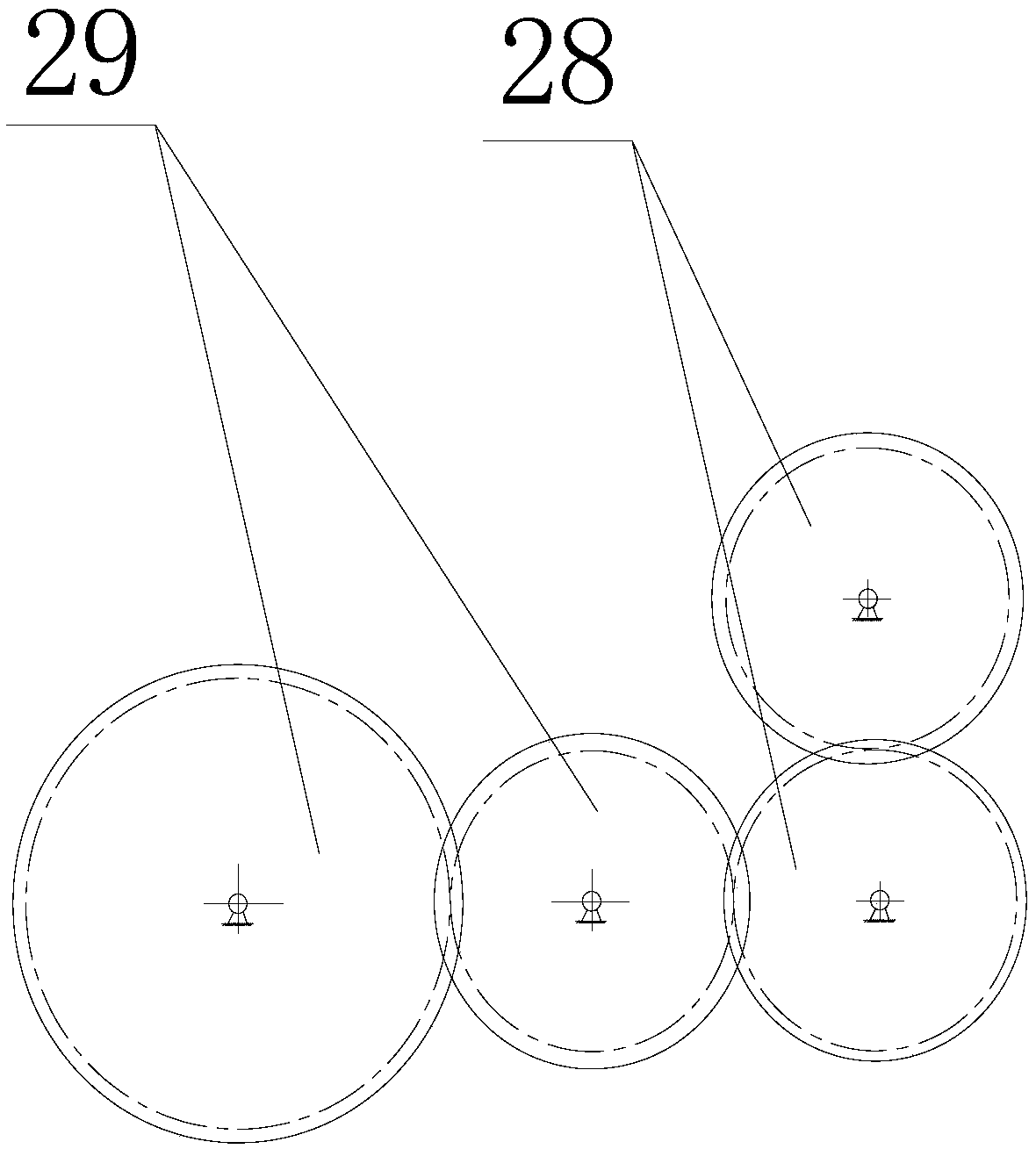

[0045] This embodiment is a kind of wood chipper. Compared with Embodiment 1, the difference is that: the first hob is vertically set (that is, the axis of the first hob is vertical), and the first hob is set between two first hobs. There is a longitudinal first crushing gap; the second hob is arranged horizontally (that is, the axis of the second hob is horizontal), and a transverse second crushing gap is set between the two second hobs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com